IN February, global mining giant Rio Tinto reported a record underlying earnings result of US$15.5 billion for the 12 months to December 31, 2011. The achievement was overshadowed, however, by the company’s 59 per cent slump in its 2011 calendar year net profit to US$5.8 billion, due mainly to a US$8.85 billion write down of its aluminium business, Rio Tinto Alcan. The impairment prompted chief executive Tom Albanese to forego his annual bonus because the purchase of the Alcan aluminium business “happened on his watch”: Rio Tinto

IN February, global mining giant Rio Tinto reported a record underlying earnings result of US$15.5 billion for the 12 months to December 31, 2011. The achievement was overshadowed, however, by the company’s 59 per cent slump in its 2011 calendar year net profit to US$5.8 billion, due mainly to a US$8.85 billion write down of its aluminium business, Rio Tinto Alcan. The impairment prompted chief executive Tom Albanese to forego his annual bonus because the purchase of the Alcan aluminium business “happened on his watch”: Rio Tinto

acquired Alcan in 2007 for US$38.1 billion at the top of the market. Chief financial officer Guy Elliott also elected not to receive his bonus for 2011 in light of the aluminium business’s performance.

In a statement, Rio Tinto reported that Rio Tinto Alcan’s underlying earnings of US$442 million were 28 per cent lower than 2010.

“Higher exchange-traded aluminium prices increased earnings by $574 million compared with 2010,” the company stated. “This was more than offset by adverse currency movements of US$282 million, mainly from the strengthening of the Canadian and Australian dollars against the US dollar, higher costs from increased input prices and the effects of adverse weather conditions in the early part of 2011, mainly in Queensland, Australia. “In the latter half of the year, the combination of lower London Metals Exchange metal prices and continued higherprices for key raw materials such as pitch, coke and caustic soda exacerbated the decline in underlying earnings.”

Rio Tinto reported that the global aluminium market in 2011 was characterised by a year of “two halves”.

“In the first half, the strong demand along with factors such as power cutbacks in China, escalating socio-political tensions in the MENA [Middle East and North Africa] region and improving macro data from OECD [Organisation for Economic Co-operation and Development] countries,

pushed the LME cash prices to a high of US$2771 per tonne in April,” the company stated “In the second half, macroeconomic concerns took hold, particularly the unfolding debt crisis in Europe, thereby reducing prices to below US$2000 per tonne towards the end of 2011, significantly

hampering earnings as a result. “The 2011 average aluminium price was US$2395 per tonne, an increase of 10 per cent on 2010.”

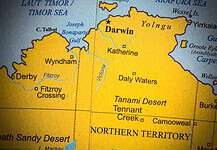

In Australia, Rio Tinto Alcan’s assets include a number of key mining, refining and smelting operations. The Gove mining operation covers a lease area of 22,625.7 hectares on the Gove Peninsula in North East Arnhem Land in the Northern Territory.

The history of European exploration in the area extends back as far as the early 1600s, but it wasn’t until 1934 that the area was settled when a Methodist mission was established to provide medical services to the local indigenous people.

Bauxite exploration began in the region in 1952 and substantial bauxite reserves were identified in 1955. In 1969, the Commonwealth Government granted special mining and special purpose leases to the Gove Joint Venture Participants, known as the Gove Agreement. The township of Nhulunbuy and associated infrastructure was established in 1972 to house mining employees.

Today, Rio Tinto Alcan’s Gove operation consists of a mine, refinery, residue disposal storage facility, port and steam power station. At full capacity, the mine can produce about 8.5 million tonnes per annum of bauxite and the refinery can produce 3.8mtpa of alumina. Gove has ore reserves of more than 180mt and the operation employs more than 800 people. Weipa mine Commercial quantities of bauxite were first discovered on Aboriginal land at Weipa, in western Cape York, in 1955 by a geologist named Harry Evans. In 1961, bauxite mining began on Cape York Peninsula, and first commercial production was achieved in 1964 when 453,365t of bauxite were mined and shipped. Today, this annual production figure has increased to more than 16 million dry product tonnes per annum. Rio Tinto Alcan owns 100 per cent of the Weipa project, which it operates under two individual land use agreements: the Western Cape Communities Coexistence Agreement and the Ely Bauxite Mining Project Agreement. These agreements provide economic, education and employment benefits, as well as cultural heritage support and formal consultation processes between the company and the area’s Traditional Owners. Rio Tinto Alcan’s ore reserves at Weipa cover more than 3800 square kilometres, and ore from the area is transported to the company’s Yarwun refinery, Queensland Alumina’s Gladstone refinery and overseas customers.

In 2008, Rio Tinto Alcan began a feasibility study and environmental impact assessment to extend the Weipa mine in an area south of the Embley River. The company reported that the South of Embley extension project could extend Weipa’s mine life by about 40 years, depending on production rates.

The key features of the project, which represents a $1.45 billion investment, are an open-cut bauxite mine, processing plant and bauxite stockpiles. Infrastructure development will include construction of beneficiation plants, a power station, warehouses, workshops, bargeand ferry facilities, ship-loading facilities and an access road.

Rio Tinto Alcan’s Yarwun refinery is 10km northwest of Gladstone in Central Queensland. The world-class operation was Rio Tinto Alcan’s first 100 per cent owned and operated alumina refinery, and utilises industry-leading technology and environmental design features. These were

also incorporated into the design of Yarwun 2, a $2.3 billion expansion to the original Yarwun refinery that will increase the operation’s alumina production from 1.4mtpa to 3.4mtpa. Yarwun 2 includes components such as a co-generation facility, which will allow for reduced greenhouse emissions intensity and enable the operation to feed surplus electricity back into the power grid.

The expansion was approved in July 2007 and is expected to begin operating in August, with first bauxite to be processed through the expanded plant in mid-2012. Yarwun is supplied with bauxite from Rio Tinto Alcan’s Weipa mine, and produces alumina for customers in Australia, New

Zealand, China and the Middle East. Yarwun uses the Bayer process to refine bauxite into alumina: grinding mills prepare the bauxite for high-temperature digestion, where aluminium hydroxide is dissolved from the bauxite into a solution of caustic liquor. The resultant liquor and solids are separated in clarifiers before the liquor is sent to precipitation and the solids are washed and pumped into residue storage. Open-top precipitation tanks allow hydroxide crystals to form from the super-saturated liquor.

These crystals are then heated in calciners to remove water molecules and produce alumina powder, which is stored for shipment to domestic and international customers. Bell Bay smelter Owned and operated by Rio Tinto Alcan, the Bell Bay aluminium smelter sits at the mouth of the Tamar River in Tasmania, about 5km from George Town and 45km from Launceston.

The smelter was the first of its kind to be built in the southern hemisphere, and began operation in 1955 as a joint venture between the Australian and Tasmanian Governments. In its first year of operation, the smelter produced just 1200t. In 1960 the business was acquired by Comalco Industries, which later became Rio Tinto Alcan.

Bell Bay is a major contributor to the economic well-being of Northern Tasmania: it creates employment, contributes significant export earnings, pays government taxes and charges, and invests directly in local communities through the purchase of goods and services plus participation in community programs. The operation continues to play a key role in the development of Bell Bay as a major industrial centre, providing a strong economic and industrial base for many industries and specialist contractors in the wider area.

The Bell Bay operation has three main processes: manufacture of carbon products; conversion of alumina to metal; and metal alloying and casting. Due to the high temperatures required for the aluminium smelting process, production at the smelter operates 24 hours a day, 365 days a year.

Electricity is a major raw material in the production of aluminium and the Bell Bay smelter is the largest industrial user of electricity in Tasmania, with its annual consumption of 322 megawatts equivalent to about 25 per cent of Tasmania’s total demand. The Bay Bell smelter produces ingot, block and T-bar products that are marketed to customers in Australia, India, Asia and the US. Ingots are cast in 8kg, 12kg and 22kg sizes; block is cast in a variety of sizes and lengths ranging in weight from 9t to 13.5t per slab; and T-bars are cast to a variety of lengths to meet customer requirements.

Rio Tinto Alcan is the largest shareholder (with 59.39 per cent), in the Boyne Smelters Limited (BSL) joint venture. The other shareholders are YKK Aluminium (9.5 per cent) SLM Australia (9.29 per cent), SLMA No. 2 (7.71 per cent), Ryowa Development II (6.46 per cent), Ryowa Development (5.19 per cent) and Sumitomo Chemical (2.46 per cent). The Boyne smelter, on Boyne Island in Queensland, has been in operation since 1982, and has undergone extensive expansion in that time. The smelter began commercial operation in 1982 and underwent a $1 billion expansion in 1997, introducing a third reduction line that increased aluminium production from 260,000tpa to more than 558,000tpa. BSL then undertook further modernisation at the smelter, re-building the operation’s carbon baking furnace 3 and constructing a new carbon baking furnace (4).

The Boyne smelter produces T-bars, ingots and billets, which are marketed to clients in Australia, Asia and the US. Restructuring for future growth In October 2011, following a strategic review, Rio Tinto announced plans to restructure and streamline its aluminium business. The company reported that it would divest 13 assets “at an appropriate point in the future”, and said some would be managed separately in the meantime by a new business unit called Pacific Aluminium.

The Gove bauxite mine and alumina refinery, Boyne smelter and associated Gladstone Power Station, and the Bell Bay smelter will fall under the jurisdiction of Pacific Aluminium. Mr Albanese said the decision was a significant step towards achieving the company’s performance targets for its aluminium product group. “We have already made good progress, with plans in place to generate sustainable performance improvement, and we are investing at a number of our core assets,”

he said. Rio Tinto Alcan chief executive Jacynthe Cote echoed Mr Albanese’s statement. “We are already well on our way to building a truly outstanding aluminium business,” she said. “Streamlining the product group allows Rio Tinto Alcan to concentrate its efforts even more on driving performance improvements and investing in growth to increase shareholder value.”

By Amy Mattes-Harris