AUSTRALIAN iron ore explorer Sherwin Iron has been given the all-clear to mine at its Roper River project in the Northern Territory after reaching an historic agreement with the National Land Council (NLC).

In a recent statement, the company said the NLC contract, which is subject to ministerial approval, was a critical milestone in securing the future of the mine and providing substantial benefits to the Traditional Owners.

Sherwin estimates that direct investment in the mine, which will create 400 jobs once fully operational, will be about $800 million.

The agreement, which was ratified at a NLC council meeting in November 2012, covers mining and exploration across all of Sherwin’s tenements and includes royalty payments.

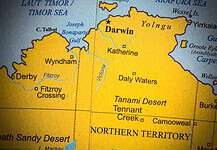

Sprawling more than 4000 square kilometres 500km southeast of Darwin, the project has a current resource of 488 million tonnes.

Sherwin expects the mine will produce 200mt of ore throughout its life, including 40mt of direct shipping ore.

“There has been a real spirit of openness and trust throughout the negotiations,” Sherwin executive chairman Barry Coulter said.

“We are all committed to achieving an outcome that brings benefits to the Traditional Owners, local people and broader Territory community.” Since reaching the transaction, Sherwin has lodged a notice of intent with the Northern Territory Government, providing an overview of the proposed project and an indication of potential impacts. “[The Notice of Intent] continues the momentum we have gained in the development phase and we will continue to progress on a number of fronts concurrently in developing this project,” Mr Coulter said.

The project was granted major project status by the Northern Territory Government earlier this year, and Sherwin is now working towards completing an environmental impact statement and receiving regulatory approval.

Explorer set to strike while the iron is hot

Advertisement