Boosting Durability and Safeguarding Assets: A Comprehensive Look at Rhino Linings’ Australian Product Lineup

In the realm of industrial coatings, Rhino Linings stands tall as a beacon of excellence. As a revered player in the industry, Rhino Linings has forged a reputation for delivering top-tier protective coatings engineered to withstand Australia’s demanding conditions. With an extensive range of products showcased on www.rhinolinings.com.au, let’s dive into the world of Rhino Linings and explore how their offerings are reshaping protection for various industries across the country.

The Rhino Linings Heritage

Before we delve into the product range, it’s crucial to appreciate Rhino Linings’ rich history. Established in 1988, the company began as a small venture specialising in spray-applied protective linings, primarily for utility vehicle trays. Over time, it has evolved into a global brand recognised for its robustness, innovation, and unwavering commitment to quality. Today, Rhino Linings has a presence in over 80 countries and offers an extensive array of protective coatings.

Unveiling the Australian Product Portfolio

1. Rhino Hybrid HB1140

Rhino Hybrid HB1140 is a versatile coating celebrated for its exceptional resistance to abrasion and wear. This coating is particularly well-suited for applications where toughness and flexibility are paramount. Industries such as agriculture, mining, and construction rely on Rhino Hybrid HB1140 to safeguard their equipment and infrastructure from the harsh Australian environment.

2. Rhino Hybrid HP1150

For applications requiring superior chemical resistance and durability, Rhino Hybrid HP1150 takes the lead. This product is a trusted choice in industrial settings where protection against corrosive substances, chemicals, and solvents is of utmost importance. From manufacturing facilities to wastewater treatment plants, Rhino Hybrid HP1150 ensures extended protection against corrosion and abrasion.

3. Rhino Extreme 1150FR

Rhino Extreme 1150FR is a high-performance coating designed to withstand extreme temperatures. With an ability to endure temperatures up to 150°C (302°F), it finds a perfect fit in industries like petrochemicals, oil and gas, and manufacturing, where exposure to extreme heat is a constant challenge.

4. Rhino HiChem 1170

Rhino HiChem 1170 is engineered for the harshest Australian conditions. This coating offers exceptional resistance to chemicals, making it indispensable for applications in chemical processing plants and other environments where protection against corrosive agents is critical.

5. Rhino PP1195

In Australia’s diverse and challenging landscapes, Rhino PP1195 shines as a protective coating for various applications. Whether it’s safeguarding marine structures, automotive components, or even recreational equipment, Rhino PP1195 delivers durable protection against abrasion, impact, and harsh weather conditions. Potable water certified.

6. Rhino TUFF STUFF

Rhino TUFF STUFF Spray-on lining creates a monolithic seamless coating, it conforms to any shape and size and will bond to virtually all substrates of any dimension, including all metals, concrete, wood and fibreglass. Potable water certified.

7. RhinoChem 2170

RhinoChem 2170 is engineered for versatility, offering protection against water, chemicals, and corrosion. Its low VOC content makes it an eco-friendly choice for those who prioritise sustainability in their projects.

8. RhinoGuard 2185

Features elastomeric properties which allows for application to surfaces subject to extreme vibration, expansion, contraction, movement, flexing, abrasion, and impact.

9. RhinoGuard 2195

Provides high tensile strength, tear strength properties, including resistance to many commercial and industrial chemicals such as acids, alkalis, oils and cleaning chemicals.

The Rhino Linings Edge

1.Unsurpassed Durability

Rhino Linings coatings are renowned for their ruggedness. They are engineered to withstand the most extreme Australian conditions, offering long-lasting protection that reduces maintenance costs and downtime.

2. Tailored Solutions

Recognising that different industries have distinct needs, Rhino Linings provides custom solutions to meet specific requirements, ensuring you get the right protection for your unique assets.

3. Expert Application Services

Rhino Linings doesn’t merely supply coatings; they offer comprehensive solutions. Their network of skilled applicators ensures coatings are correctly applied, adhering to the highest quality standards.

4. Sustainability Commitment

In an era of heightened environmental awareness, Rhino Linings leads the way with industry leading coatings which reduce environmental impact while delivering top-tier protection.

Real-World Applications

Let’s explore real-world applications of Rhino Linings products in Australia:

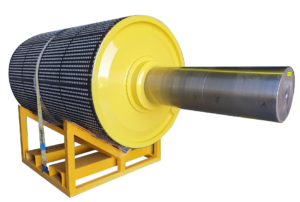

1. Mining Equipment

Rhino Linings mine site protective coatings include thick polyurethane and polyurea linings. These are the optimal solution for your mine site protective coatings requirements reducing costs and increasing equipment return on investment for mining and aggregate operations.

2. Flooring Solutions

3. Containment Solutions

Rhino Linings polyurethane and polyurea formulations offers superior solutions for reliable, impervious primary and secondary containment. The coatings have been specifically designed to reduce containment maintenance costs and maximise equipment return on investment.

Conclusion

In a country where durability and protection are non-negotiable, Rhino Linings stands as an industry leader. Their commitment to innovation, quality, and sustainability has made them a trusted choice across diverse Australian industries. Whether it’s protecting valuable assets from corrosion, guarding against chemical exposure, or enduring extreme temperatures, Rhino Linings’ product portfolio offers the solution.

As industries evolve and confront new challenges, Rhino Linings remains at the forefront, dedicated to providing the ultimate protection that keeps Australian businesses moving forward. Explore the possibilities on www.rhinolinings.com.au and discover how Rhino Linings can elevate the durability and longevity of your assets and infrastructure in the Land Down Under.

Discuss your requirements with the Rhino Linings Team by calling +61 7 5585 7030