MINING is a tough game.

It all comes down to how much material you can extract for the least amount of money and any interruptions to that extraction process cost companies many, many thousands of dollars.

Specialising in on-site earthmover and OTR machinery tyres, OTR Tyres’ expert team of mobile tyre technicians manage a fleet of field service units and tyre fitting trucks for all on-site fitting and maintenance.

OTR staff are experts in the mobilisation and de-mobilisation of heavy equipment, working to minimise downtime for tyre removal and re-fitting once on site.

With global sourcing and supply capacity, OTR Tyres has the ability to source the right tyres and wheels for your requirements and is the chosen project partner for major state, national and international projects.

OTR Tyres has factory direct access to all product categories and the capacity to ensure continuity of supply of competitively priced tyres of all segments, from budget to premium brands.

It can also arrange tyre disposal and offer trade-in services.

OTR Tyres’ extensive range of new and used (quality part-worn) OTR tyres offers a real commercial advantage, particularly if preparing machinery for sale, or if to match with existing tyres in service.

OTR Tyres combines world class facilities, tools and equipment with professional and experienced technicians to ensure tyres are serviced to the highest standards.

The team of tyre fitters and service technicians are highly trained and assessed regularly to ensure compliance to industry best practice.

The company offers a comprehensive range of tyre service and repair options including on-site coverage, call-outs and emergency repairs.

With a fast and reliable turnaround for all inspection and repairs, your equipment will be back on the road as soon as possible.

Get rid of flats for good

Have your operations ever been disrupted due to tyre failure?

One method that is proven to extend tyre life, eliminate punctures and virtually eradicate unexpected tyre repairs, is the use of solid filling.

The process involves filling the void in the tyre with a compound other than air to make it impervious to punctures or ruptures. Technology advances and one of the most highly adopted solid fill products in the world, Carpenter’s world-leading Rely T-25 compound, has proven itself time and again to reduce solid-shock and give drivers the same ride as pneumatic tyres.

Rely T-25 is available from TyreFill WA, part of OTR Tyres, based in Bellevue, WA.

TyreFill WA has been solid filling tyres for use in mining, agriculture, civil construction and aerial platforms for many years.

That experience has enabled the company to develop techniques to not only completely fill tyres and eliminate air pockets but also to set the ‘tyre pressure’ to OEM specs and, being a solid compound, that pressure does not vary for the life of the tyre.

A special storage and mixing facility is required to fill tyres with Rely T-25 as each of the two parts of the polymer compound must be stored at a specific temperature.

Dual pumps are used to draw Part A and Part B from their individual containers and push them through a mixing screw before the combined liquid compound is forced through the valve of the tyre, which is mounted to the rim.

As the tyre fill compound enters the tyre, displaced air exits from a vent hole – just like bleeding a brake cylinder.

Once the tyre is filled with exactly the right volume of T-25 to give the required working pressure, it is allowed to set for 48-hours. From that point the tyre is flat-proofed and will be serviceable, without fail, until the tread is worn down to the witness marks.

Benefits of solid filling

The benefits of solid filling tyres are manifold as they become impervious to nails, spikes, slag and rocks.

TyreFill WA’s solid fill is an investment that pays for itself.

Asset downtime is a costly exercise for any mining operation and unexpected tyre maintenance and replacement can often sideline equipment for days at a time.

By solid filling their tyres, mining operations save on expensive flat tyre repair and service charges, extend the service life of their tyres, eliminate interrupted work schedules, eliminate costly down time due to flats, and increase job productivity.

Improved safety is another significant advantage of solid filling tyres.

The process eliminates sudden loss of pressure, helps to handle overload situations, lowers the machine’s centre of gravity to reduce roll-over possibilities and improves traction.

Once the tyre is filled and fully, cured the chances of tyre failures and blowouts are eliminated, improving on-site safety.

Tyres that are improperly inflated pneumatically, wear out sooner due to over or under-inflation.

Tyres filled with TyreFill WA’s solid fill are pressurised to manufacturer specifications and will stay that way throughout the tyre’s life.

Rely T-25 filled tyres can be run continually at 56kph or for up to two hours in an eight-hour period at 88kph.

OTR tyres, wheels, servicing and repairs

OTR Tyres is a WA success story, having tyre supply and service contracts with the country’s largest mining operations and an assembled fleet of 16 service trucks to handle tyre repairs and fitting for clients right across WA.

OTR’s experienced and knowledgeable technicians are wheel experts, providing engineering consultancy with the design of wheel assemblies most suited to meet both machine and project requirements and working closely with all customers to ensure optimum products are supplied.

They also consider the equipment type, operating environments, tyre size and load capacity expectations.

OTR Tyres also conducts in-house wheel examination, NDT testing, repair and certification for mandatory 10,000-hour inspections and is able to blast and repair rims or supply new components accordingly.

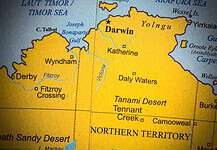

With branches in Bellevue, Port Hedland, Karratha and Kalgoorlie and a depot in Yatala, QLD, OTR Tyres has stock, equipment and personnel close at hand for their mining customers.

Source:

OTR Tyres/TyreFill WA

08 9250 8949