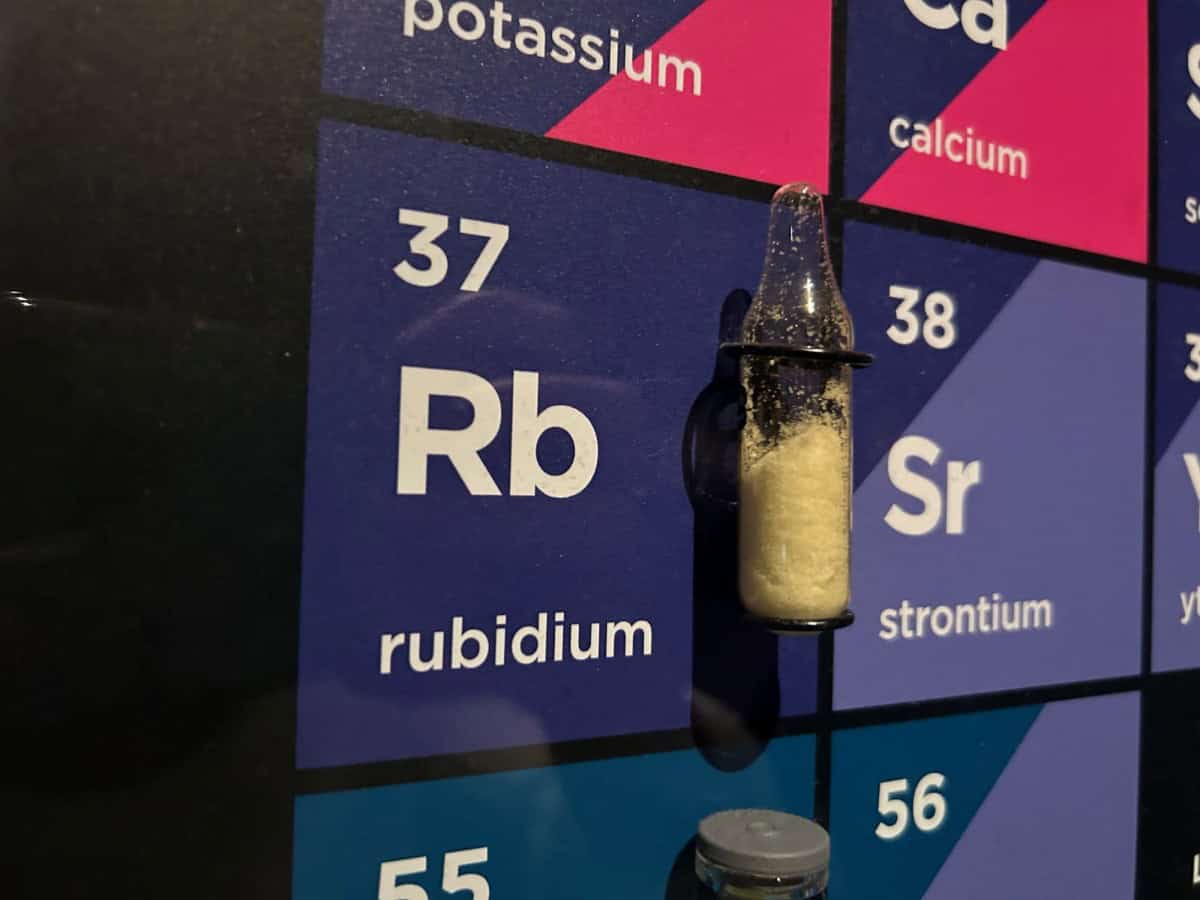

Researchers from Edith Cowan University’s (ECU) Mineral Recovery Research Centre have successfully demonstrated the direct extraction of rubidium from ore samples supplied by Everest Metals Corporation (ASX: EMC).

What began as discussions around lithium extraction at Everest Metal’s Mt Edon project in WA turned into how to best extract rubidium with lithium as a by-product.

A research agreement was executed earlier this year around this, with the first stage involving a small-scale laboratory demonstration of all the processing steps in the recovery of rubidium using advanced processes such as ion exchange.

Rubidium is designated a critical mineral by the US Government and is often associated with caesium and lithium mineralisation.

Its compounds are used in biomedical research, electronics, speciality glass, pyrotechnics and military industrial applications.

Approximately 80% of rubidium is used in the research and development of high-tech applications, including the development of new energy conversion technologies and new communication technologies.

Compared with the previous methods of extracting rubidium which involves destructive methods and a leaching process, the direct extraction offers a range of environmental and economic benefits.

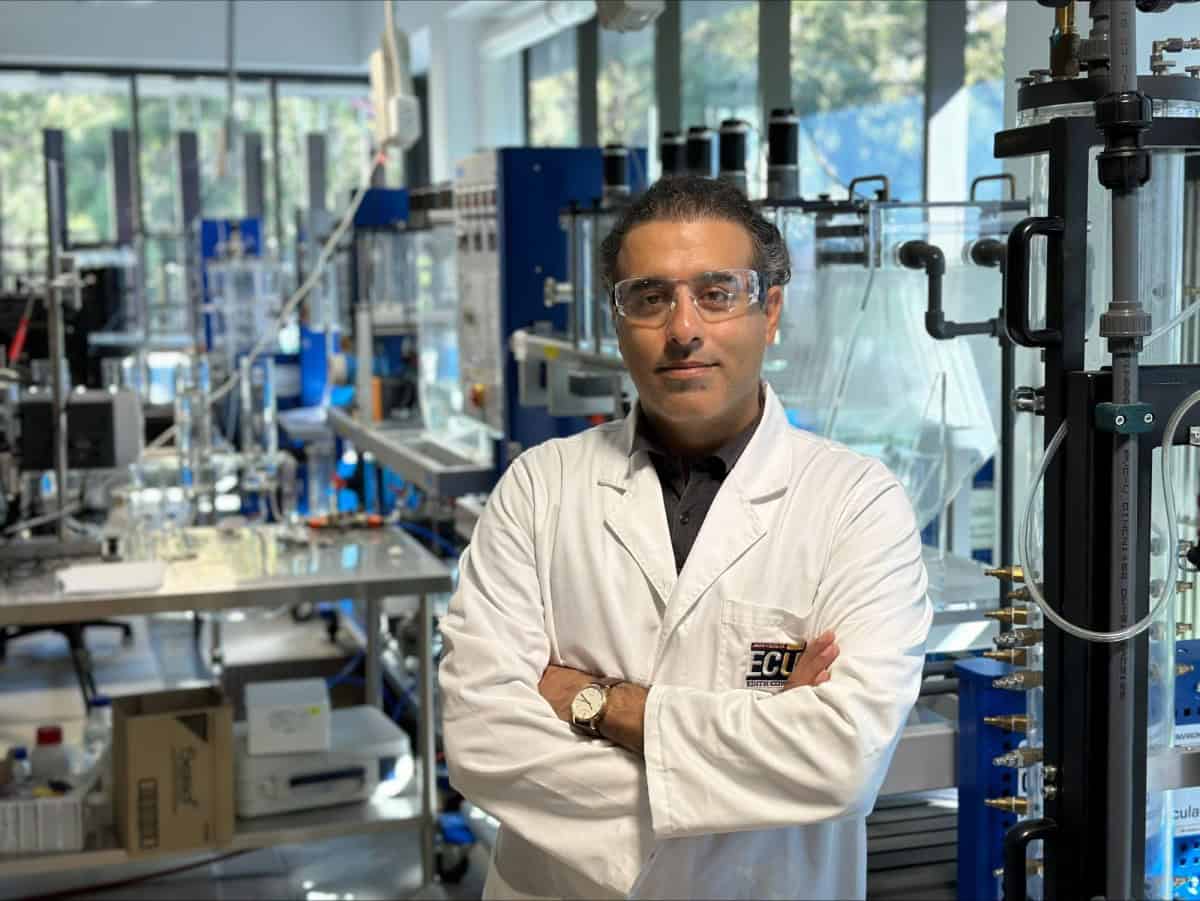

ECU Associate Professor Amir Razmajou comments on this.

“Traditional mineral processing is very energy and water intensive,” he said.

“Our aim with the direct rubidium extraction is to lower the carbon footprint of the operation.

“Our process also allows us to recycle water, which will reduce the water consumption rate for this project.

“Additionally, the project development would be modular, meaning that the technology is easy to scale up to ramp-up production.”

Over the coming months, the ECU researchers will undertake purification work on the rubidium extracted to-date.

“We are working towards producing a few grammes of high-grade rubidium to prove the concept of the technology and the extraction process that we have developed,” Professor Razmjou said.

“Following that, we will work towards a piloting plant and ultimately a demonstration plant.”

While the intellectual property derived under the research agreement with Everest Metals will remain with the company, Professor Razmjou says that there is significant potential to adapt the process to extract other resources in a similar way.

“Depending on the deposit, and the economy of the project, the direct extraction method could be deployed for other types of minerals.”