ASPEC Engineering and the Amrun Project

A benchmark in materials handling Innovation

ASPEC Engineering is a specialist consultancy with a strong reputation in the design, assessment and delivery of materials handling systems across Australia’s mining and port sectors.

With decades of experience, ASPEC has built a unique expertise in mobile, rail-mounted materials handling machines, including stackers, reclaimers and shiploaders. Its work spans from early-stage concept and feasibility studies to detailed design audits and on-site commissioning support, ensuring practical and innovative engineering solutions for complex industrial environments.

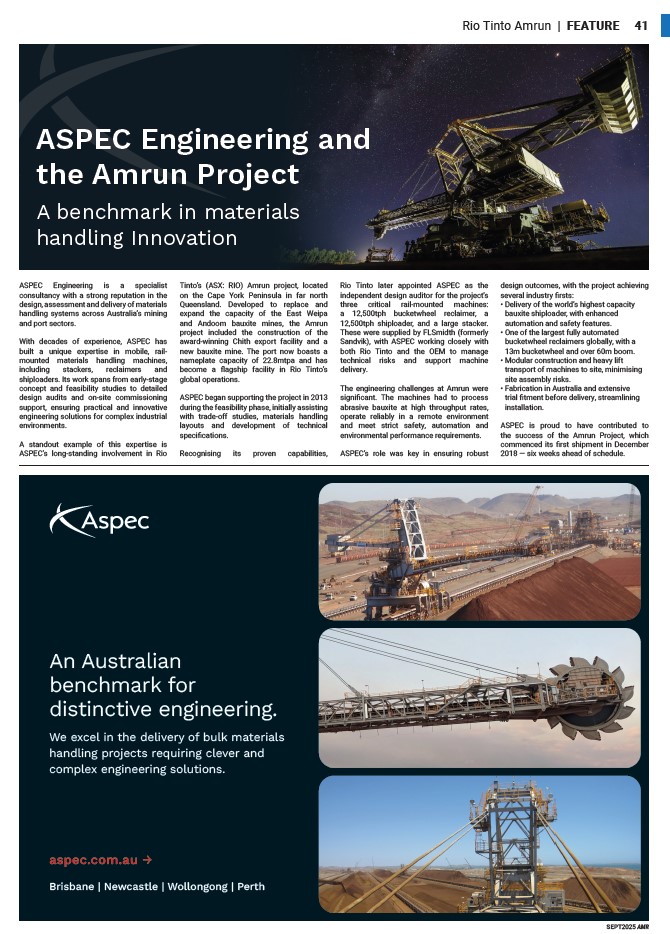

A standout example of this expertise is ASPEC’s long-standing involvement in Rio Tinto’s (ASX: RIO) Amrun project, located on the Cape York Peninsula in far north Queensland. Developed to replace and expand the capacity of the East Weipa and Andoom bauxite mines, the Amrun project included the construction of the award-winning Chith export facility and a new bauxite mine. The port now boasts a nameplate capacity of 22.8mtpa and has become a flagship facility in Rio Tinto’s global operations.

ASPEC began supporting the project in 2013 during the feasibility phase, initially assisting with trade-off studies, materials handling layouts and development of technical specifications.

Recognising its proven capabilities, Rio Tinto later appointed ASPEC as the independent design auditor for the project’s three critical rail-mounted machines: a 12,500tph bucketwheel reclaimer, a 12,500tph shiploader, and a large stacker. These were supplied by FLSmidth (formerly Sandvik), with ASPEC working closely with both Rio Tinto and the OEM to manage technical risks and support machine delivery.

The engineering challenges at Amrun were significant. The machines had to process abrasive bauxite at high throughput rates, operate reliably in a remote environment and meet strict safety, automation and environmental performance requirements.

ASPEC’s role was key in ensuring robust design outcomes, with the project achieving several industry firsts:

- Delivery of the world’s highest capacity bauxite shiploader, with enhanced automation and safety features.

- One of the largest fully automated bucketwheel reclaimers globally, with a 13m bucketwheel and over 60m boom.

- Modular construction and heavy lift transport of machines to site, minimising site assembly risks.

- Fabrication in Australia and extensive trial fitment before delivery, streamlining installation.

ASPEC is proud to have contributed to the success of the Amrun Project, which commenced its first shipment in December 2018 — six weeks ahead of schedule.