Fabrum and Fortescue commission liquid hydrogen plant

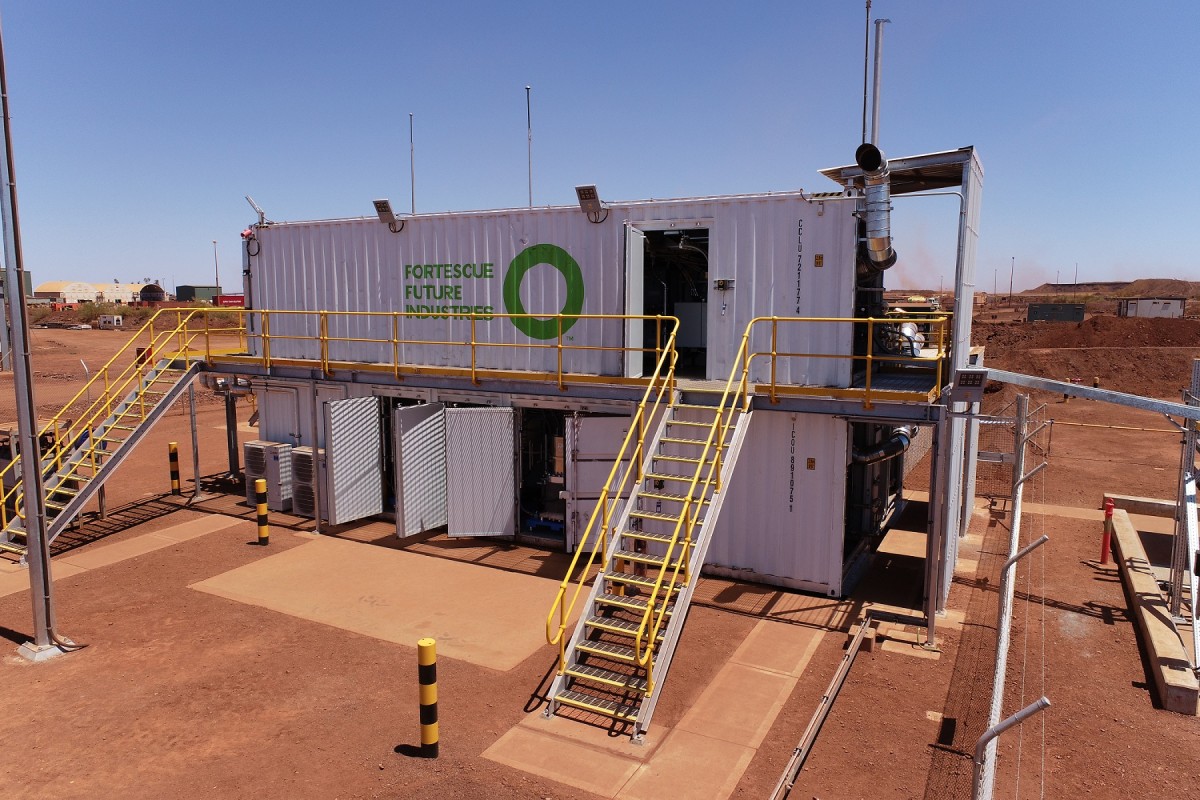

Manufacturing company Fabrum has collaborated on the design, build and commissioning of Australia’s largest liquid hydrogen plant at a mine site.

The liquid hydrogen plant at Fortescue’s Christmas Creek mine in WA comprises of a hydrogen liquefaction facility, liquid hydrogen storage and a liquid hydrogen refuelling station, was unveiled today.

Liquid hydrogen will be used to power Fortescue’s zero-emission mining equipment prototypes, including the offboard power unit and the hydrogen-powered haul truck prototype.

The liquid hydrogen plant can produce around 350kg of liquid hydrogen per day and has 600kg of storage.

Fabrum chief executive Dr Ojas Mahapatra commented on the milestone.

“This is the first project we’ve collaborated on with Fortescue and it highlights the great opportunities we see to help each other be successful in the future,” he said.

“This project also represents our entry into the mining and minerals industry to add to our work in heavy transport, aviation and other industries.

“It’s an exciting time for Fabrum as we continue to grow rapidly to meet increasing global demand for hydrogen production systems and other technologies.”

Fortescue chief executive Dino Otranto says this renewable hydrogen plant is versatile.

“Hydrogen and fuels made using renewable energy will have a role to play in decarbonising mining, whether it’s in buses, heavy mining equipment such as haul trucks and excavators, or producing green iron,” he said.

“This renewable hydrogen plant enables us to produce gaseous and liquid hydrogen to be used to power our mining equipment prototypes, while also providing the added benefit of refuelling our fleet of coaches at Christmas Creek.”