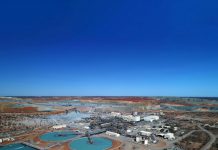

First production at Kathleen Valley imminent

Construction of the process plant was substantially completed in the June quarter at Liontown Resources’ (ASX: LTR) Kathleen Valley lithium project in WA.

Construction of the process plant was substantially complete by the end of the quarter, achieving 99% overall completion.

Dry plant

After beginning dry plant commissioning ahead of schedule in March, Liontown used the June quarter to focus on increasing throughput and driving circuit optimisations in the crushing circuit to the fine ore bin.

At the end of the quarter, 58kt of crushed ore was stockpiled for commissioning the SAG mill and wet plant.

Wet plant

Efficiently transitioning from construction to commissioning the wet plant was a key focus for Liontown in the quarter with mechanical and electrical commissioning of the plant executed to schedule.

Increasing the commissioning resources saw a significant ramp up in June with peak levels reached and expected to continue until July.

Underground mining

Significant progress was made in underground mining throughout the quarter, with 1596m recorded, bringing the total development metres to around 3500m since underground mining began in November 2023.

Underground operations remain on schedule for first development ore in August and first production of ore from the stoping cycle by the end of 2024.

Open pit mining

Significant progress was also made with mining at the Kathleen’s Corner open pit and contractor Iron Mine Contracting remains on track to reach the primary ore zone in early September.

Despite multiple rain events, 1.3m bulk cubic metres (bcm) were mined, contributing to 216kt of clean ore stockpiled ahead of initial production. Since January 2023, around 7.7mbcm has been moved.

Ore sorting product project

The ore sorting product (OSP) project is continuing on schedule, focusing exclusively on processing ore containing gabbro (dense, mafic intrusive rock).

Ore sorting and mobile crushing production rates are near design levels with production of around 11kt sorted since work commenced in April 2024.

Initial results show significant improvements in grade and gabbro rejection, consistent with laboratory-based test work.

Paste fill plant

In the quarter, Liontown signed an engineering, procurement and construction contract with GR Engineering Services for the installation and commissioning of a paste fill plant at Kathleen Valley to support underground mining operations.

Construction of the paste fill plant is over 60% complete, with structural, mechanical, piping and electrical installation works progressing as scheduled.

Cash

Liontown burnt through nearly $39m in the quarter with the majority going towards production costs. Funds were also used for administration and corporate costs, plus exploration and evaluation.

The company ended the quarter with just under $123m in total available funds, representing three quarters left of funding available.

Liontown managing director Tony Ottaviano commented on the quarter.

“Following another huge effort from our project team and contractors, we finished the June quarter on the cusp of completing the development required for first production at Kathleen Valley,” he said.

“In the meantime, we remain focused on achieving first production, ramp-up and solidifying Liontown’s position as a major new producer and supplier of lithium raw materials.”