Lithium extraction technology takes step towards greener future

ElectraLith, a spinout company from Monash University, has proven its direct lithium extraction and refining (DLE-R) technology can produce battery-grade lithium hydroxide using no water, no chemicals and minimal energy.

Backed by Rio Tinto (ASX: RIO), IP Group and Monash Investment Holdings, the DLE-R technology can produce battery-grade lithium hydroxide from a range of lithium sources, including salar brines, geothermal oilfield brines and spodumene leach in locations across Australia, Argentina and the United States.

This technology is emerging as the cleanest, most versatile and cost-efficient method for extracting and refining lithium.

Most lithium extracting processes are costly and have negative impacts on the environment, such as carbon dioxide emissions, mineral waste and chemical pollution.

DLE-R uses electro-membrane and electrodialysis technology to extract and produce battery-grade lithium hydroxide in a single, scalable and modular step.

ElectraLith chief executive Charlie McGill welcomed the breakthrough.

“These results validate the true potential of DLE-R across lithium resource type, quality and concentration,” he said.

“We’re particularly excited about the Paradox Basin Utah result, where DLE-R produced 99.9% pure lithium hydroxide from Mandrake’s geothermal oilfield brines without water, an increasingly scarce resource in the broader Colorado River Basin.

“This, coupled with the production of lithium hydroxide from a brine with less than 60ppm, demonstrates that DLE-R can unlock otherwise impracticable strategic reserves in the United States and Australia.”

Mandrake chief executive James Allchurch says the company plans to deploy the technology in one of the driest areas in North America.

“The outstanding performance of the DLE-R process is a critical step forward for Mandrake as we seek to commercialise our expansive Utah lithium project,” he said.

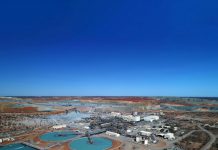

“DLE-R is perfectly suited to the water chemistry of the Paradox Basin and we look forward to partnering with ElectraLith in processing larger volumes of brine from the Utah lithium project.” ElectraLith and Rio will trial and test the first DLE-R prototype at Rio’s Rincon project in Argentina in 2026.