High-Performance Protective Coatings for Mining Operations

Mining is one of the most demanding industries, with equipment and infrastructure constantly subjected to extreme wear and tear. From abrasive materials to harsh chemicals and fluctuating temperatures, the environment poses relentless challenges. Protecting and enhancing the lifespan of these assets is critical to maintaining operational efficiency and controlling costs. That’s where high-performance protective coatings make all the difference. At Rhino Linings Australasia, we’re proud to offer solutions designed specifically to meet the unique needs of the mining industry.

Why Protective Coatings Are Essential in Mining

Mining operations expose equipment and structures to some of the harshest conditions imaginable. The consequences of neglecting protective measures can include frequent equipment failures, costly downtime, and increased maintenance expenses. Protective coatings provide an effective barrier, delivering the following key benefits:

-

Preventing Corrosion

Mining environments often involve exposure to water, chemicals, and other corrosive substances that can quickly degrade machinery. Protective coatings help prevent rust and corrosion, one of the leading causes of equipment failure.

-

Minimising Abrasion

Constant friction, impact, and abrasive materials can wear down surfaces rapidly. High-performance coatings act as a shield, reducing wear and extending the operational lifespan of machinery.

-

Improving Safety

Protective coatings also enhance safety by offering slip-resistant surfaces and preserving the structural integrity of equipment and infrastructure.

Rhino Linings Australasia: Trusted Experts in Protective Coatings

Rhino Linings Australasia: Trusted Experts in Protective Coatings

At Rhino Linings Australasia, we specialise in developing coatings that stand up to the rigours of the mining industry. Here’s what sets our products apart:

-

Unmatched Durability

Our coatings are engineered to deliver exceptional durability, offering long-lasting protection even in the toughest conditions. This reduces the frequency of maintenance and lowers overall costs.

-

Versatility

Rhino Linings coatings can be applied to a wide variety of surfaces, including metal, concrete, and timber. This versatility makes them ideal for use across all areas of mining operations, from heavy machinery to structural components.

-

Customised Solutions

Every mining operation has unique challenges. That’s why we provide tailored coating solutions to address specific needs, whether for vehicles, conveyor systems, tanks, or pipelines.

-

Expert Application

Proper application is vital to the effectiveness of any protective coating. Our skilled team ensures precise and efficient application, maximising the performance and longevity of the coating.

Applications of Protective Coatings in Mining

Rhino Linings protective coatings are designed to deliver top performance across a variety of mining applications, including:

-

Heavy Equipment

Excavators, dump trucks, and drilling rigs face daily exposure to abrasive materials and harsh conditions. Our coatings provide superior protection against abrasion and corrosion, helping equipment operate more reliably.

-

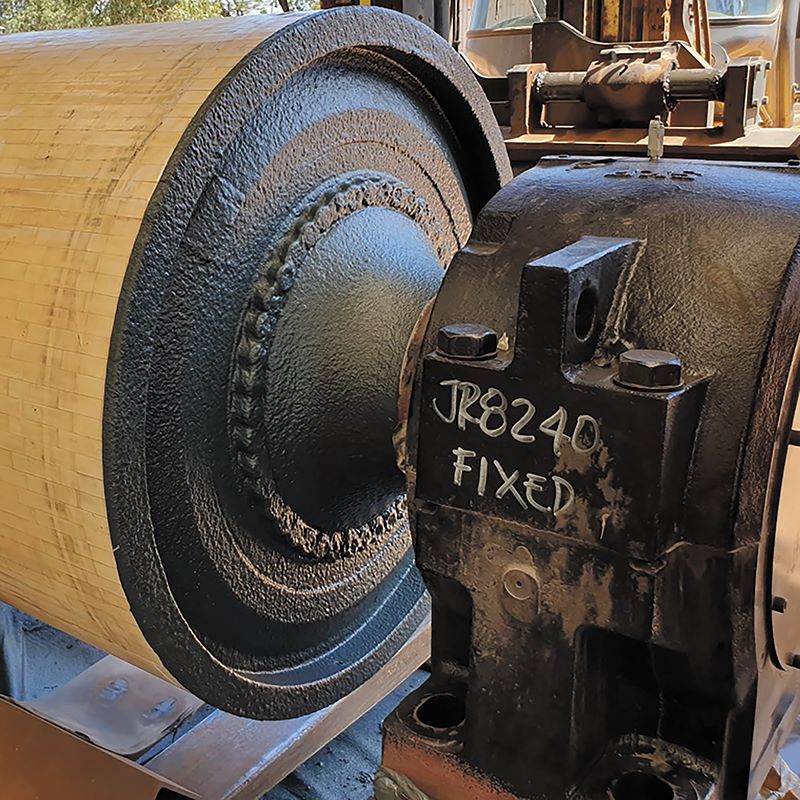

Conveyor Systems

Critical for transporting materials, conveyor systems endure significant wear and tear. Coatings protect these systems, reducing breakdowns and prolonging their operational life.

-

Storage Tanks and Silos

Protecting storage tanks and silos from corrosion is essential for preserving the quality of stored materials and maintaining structural integrity. Our coatings form a seamless barrier to prevent leaks and contamination.

-

Pipelines

The transport of liquids and slurries in mining operations places immense strain on pipelines. Our coatings safeguard both the internal and external surfaces of pipes, ensuring smooth operation and reducing maintenance requirements.

Environmental and Economic Benefits

Protective coatings don’t just safeguard assets; they also contribute to environmental sustainability and cost efficiency. Here’s how:

-

Reduced Environmental Impact

By extending the life of equipment and infrastructure, protective coatings minimise waste and reduce the need for frequent replacements, leading to a smaller environmental footprint.

-

Significant Cost Savings

Investing in high-quality protective coatings can lead to substantial savings over time. With fewer repairs, less downtime, and longer-lasting assets, operational costs are significantly reduced.

-

Enhanced Efficiency

Equipment that’s well-protected and maintained operates more efficiently, consuming less energy and boosting overall productivity. This improves the bottom line for mining operations.

Why Choose Rhino Linings Australasia?

When it comes to protective coatings, Rhino Linings Australasia is the trusted name in the mining industry. Here’s why:

When it comes to protective coatings, Rhino Linings Australasia is the trusted name in the mining industry. Here’s why:

-

Proven Performance

Our coatings have a track record of delivering reliable, high-performance solutions for mining companies across Australia.

-

Innovative Technology

We continuously refine our products to incorporate the latest advancements in coating technology, ensuring they meet the evolving demands of the mining sector.

-

Dedicated Support

We’re committed to providing exceptional customer service, offering ongoing support and guidance to help our clients get the most out of our products.

Conclusion

In the demanding world of mining, protecting equipment and infrastructure is essential to ensure durability, safety, and efficiency. Rhino Linings Australasia offers high-performance protective coatings that deliver on all fronts, reducing maintenance costs and extending the life of valuable assets. Whether you’re protecting heavy machinery, pipelines, or storage tanks, our coatings are designed to withstand the toughest conditions and help your operation thrive.

For more information about our protective coatings and how they can benefit your mining operations, visit Rhino Linings Australasia or call +61 7 5585 7030 today.