When you’re operating heavy machinery in the toughest mining environments on earth, failure of critical components like hydraulics, hoses, couplings or power transmission equipment can be catastrophic.

Replacement parts for OEM assemblies can take an average of 2.5 days to arrive by airfreight, while operators face significant downtime per incident. Then, each piece of failed equipment can cost between $500,000 and $600,000 in downtime for maintenance and repair annually.

Simply, wasted seconds mean wasted money. That’s why you need to power your mining operations with equipment you can count on.

Whether it’s trucks, hydraulic shovels, dozers, scrapers, drill rigs, rockbreakers, hydrostatic drives, or off-road vehicles, Gates Australia offer a complete line of quality components that not only keep mines productive and improve equipment uptime, but help reduce inventory expenses and get replacement parts faster.

For over a century, Gates has been a trusted source for fluid power and power transmission solutions, levelling up their engineered product solutions to meet the harsh demands of the industrial and mining industries.

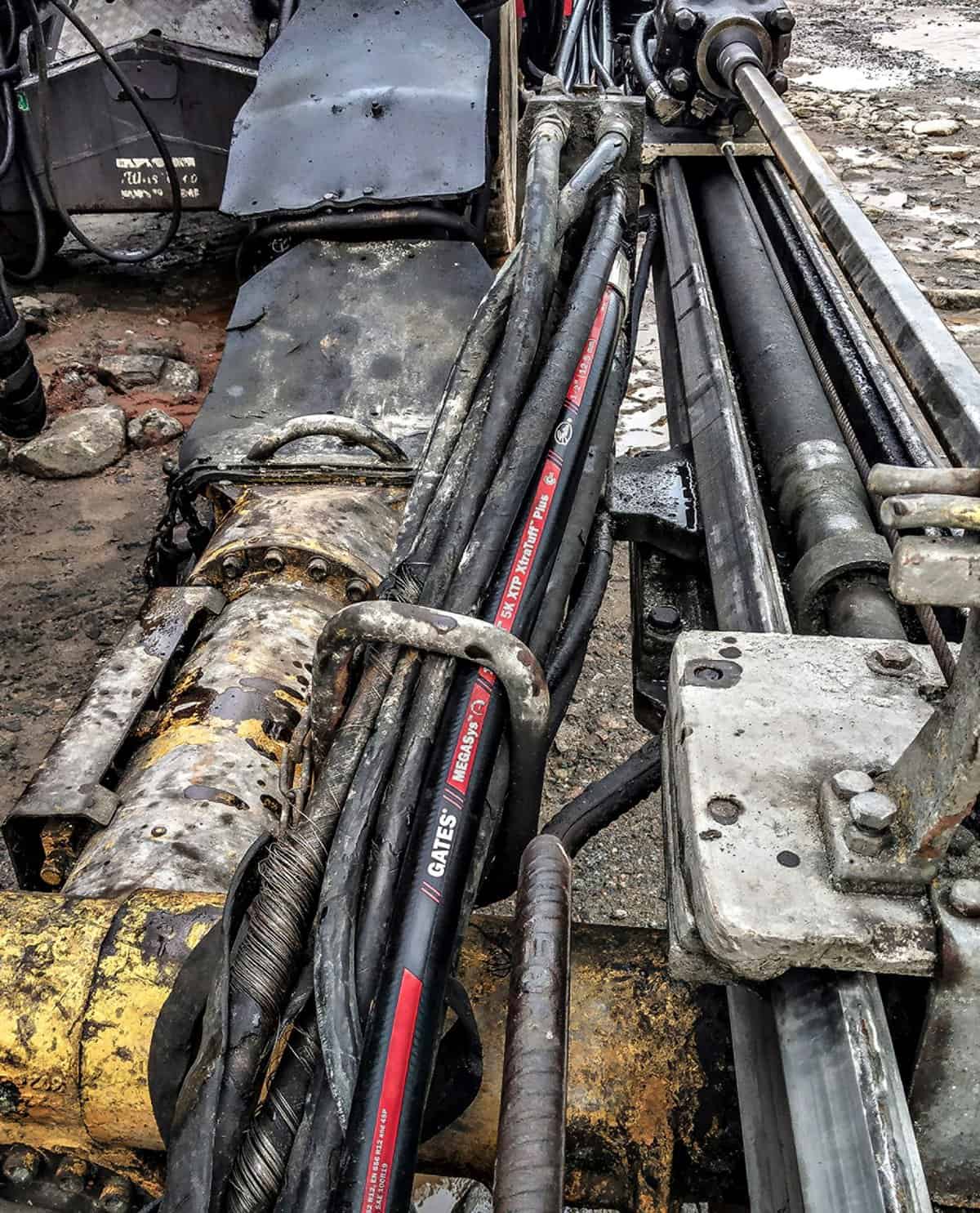

Gates’ hydraulic systems transmit power to all types of machines. However, it’s the company’s new class of high-pressure hydraulic hoses that are redefining performance for industrial and mobile equipment requirements.

Gates Industrial Fluid Power Product Manager, Arshad Ashroff, said that their MegaSys MXG 4K and 5K hydraulic hoses are engineered with productivity, equipment uptime, and durability in mind. “Integrating proprietary application of materials science and processing technology, we’ve been able to design next-level performance hoses that are lighter, smaller OD, tougher and more agile.”

High-Pressure Performance Redefined

Where others see a hose, Gates see a solution. The MXG™ 4K (4,000 psi max pressure) and MXG™ 5K (5,000 psi max pressure) hydraulic hoses exceed the pressure and performance of wire spiral constructions, but with the lower weight and flexibility driven by Gates’ patented Xpiral™ technology.

Where others see a hose, Gates see a solution. The MXG™ 4K (4,000 psi max pressure) and MXG™ 5K (5,000 psi max pressure) hydraulic hoses exceed the pressure and performance of wire spiral constructions, but with the lower weight and flexibility driven by Gates’ patented Xpiral™ technology.

“This woven spiral technology is lightweight, highly flexible, and qualified to one million impulse cycles with Gates’ GS couplings, which is a drop-in replacement for conventional spiral hoses,” said Ashroff.

“They also feature our XtraTuff Plus abrasion resistant cover, which offers improved ozone resistance, withstands operating temperatures up to 121°C, and delivers exceptional durability to power the most demanding fluid power applications. The XtraTuff™ cover provides 25 times the abrasion resistance of standard covers.”

————

Experience Unparalleled Performance

Gates MXG™ 4K and MXG™ 5K hydraulic hoses are engineered for long-lasting performance in rugged environments. They are lighter and more flexible, making them easy to transport and install, which reduces costs. Their compact design also means they take up less space where limited storage is available (force-to-bend is 25% better and OD is 5% smaller).

Gates MXG™ 4K and MXG™ 5K hydraulic hoses are engineered for long-lasting performance in rugged environments. They are lighter and more flexible, making them easy to transport and install, which reduces costs. Their compact design also means they take up less space where limited storage is available (force-to-bend is 25% better and OD is 5% smaller).

- Tested to 1,000,000 impulse cycles (3 x industry standard)

- 30% lighter than traditional spiral-wire hose

- 40% more flexible than traditional spiral-wire hose

- 5% more compact than traditional spiral-wire hose

- Temperature range: -40oC to +121oC (-40oF to +250oF)

- Certified MSHA Flame Resistant

- Exceed SAE 100R19 for inventory consolidation

- Exceed performance criteria of ISO 18752 350DC, SAE 100R13, EN856 R13, and ISO 3862 R13; sizes -10, -12 and -16 also rated for EN856 4SP

- All MXG hoses utilise Gates’ innovative Xpiral™ technology, which features 4 layers of high-tensile steel wire reinforcement

- All MXG hoses come with Gates’ XtraTuff™ Plus cover that provides 25x more abrasion resistance and 800+ hours of ozone resistance compared to standard hose covers

————

Contact Gates Australia

200 National Drive, Dandenong South VIC 3175

T: +61 3 9797 9688