Fortescue and the road to real zero

Greenhouse gas emissions are one of the main causes of global warming and according to the CSIRO’s June 2023 update, Australia emitted 465.2mt of carbon dioxide equivalent, a 0.8% increase compared to June 2022.

Energy production is the largest contributor with energy (burning fossil fuels) and stationary energy (mining, manufacturing and residential) contributing to 32.6% and 22.3% of the total emissions, respectively.

Mining giant Fortescue (ASX: FMG) is just one of Australia’s many mining companies aiming to reduce its carbon footprint and is leading the sector regarding its response to customer, community and investor expectation to reduce and eliminate carbon emissions.

The company’s Eliwana mine in WA is on track to become the company’s first site to go green through its deployment of renewable energy generation and battery storage, followed by the deployment of a zero-emission mining fleet.

The Australian Mining Review spoke with Fortescue general manager Eliwana, Vanessa Forster, about the company’s Eliwana mine and the shift towards electric vehicles.

“Eliwana will be one of the first of our sites to go green as we not only move toward electric excavators and battery electric haul trucks, but also through powering the site with green energy,” she said.

“This will mean the whole operational ecosystem, including forklifts, lighting plants, light vehicles, floor sweepers, generators and beyond will all eventually be powered by green energy.”

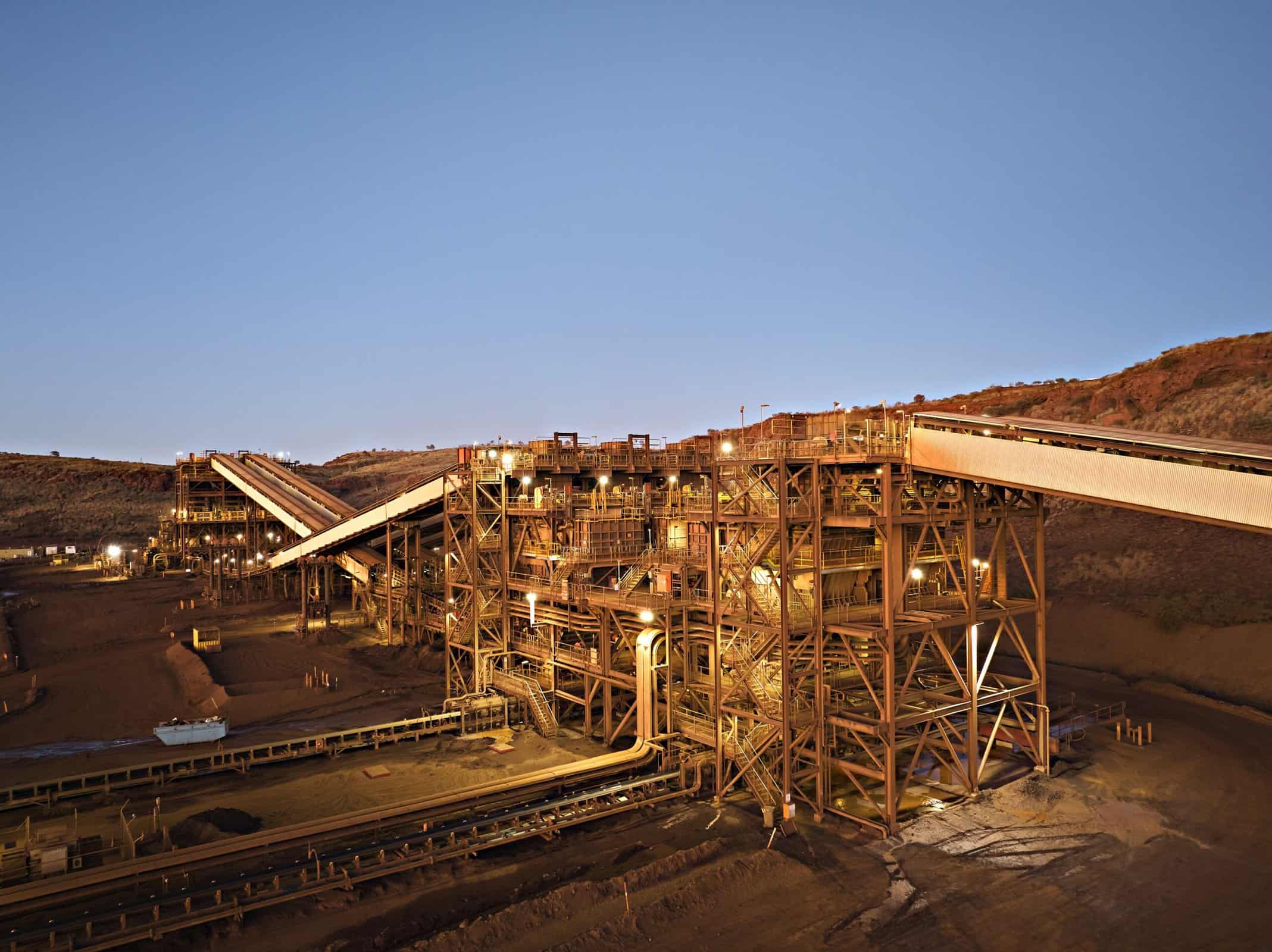

Beginning operations in December 2020, Eliwana produces a premium high-grade hematite product — known as Western Pilbara Fines — which complements the company’s Fortescue Blend.

The mine includes a 30mtpa dry ore processing facility and 143km of rail which links the mine to the Hamersley rail line.

The ore processing facility and dual stacker reclaimer means Eliwana has the capacity to direct load onto trains up to 9000tph.

Eliwana is now producing at an annualised run rate of 30mtpa, contributing to Fortescue’s low-cost status and providing greater flexibility to capitalise on market dynamics.

Green Revolution

After releasing its decarbonisation roadmap in September 2022, Fortescue aims to reduce operating costs by eliminating spend on diesel, natural gas and carbon offsets.

“In executing our roadmap, we are using well-established technologies and, in some cases, using those technologies in new ways,” Ms Forster said.

“We believe battery electric, green hydrogen and green ammonia will be critical, and we are taking practical steps to apply the best solution to each different situation.

“Eliwana will be one of our first sites to transition to real zero.

“Real zero means no fossil fuels, and where possible, no offsets.”

In October 2023, Fortescue received its first T 264 haul truck at Eliwana from Liebherr, forming part of a deal for the supply of 120 zero emission T 264 trucks to be deployed to Fortescue by 2030.

The first trucks will be diesel powered and converted to Fortescue’s in-house battery solution — developed by Fortescue WAE — before the end of the decade.

“The Pilbara Energy Connect (PEC) project, together with the Chichester Solar Gas Hybrid Project, will deliver up to 25% of our daytime stationary energy requirements from solar power by FY25,” Ms Forster added.

“The project will enable renewable electricity generated at any of Fortescue’s sites to move between our operations in Port Hedland, Iron Bridge, Cloudbreak, Christmas Creek, Solomon and Eliwana, via over 500km of transmission lines.”

In late 2023, construction began on a 132km transmission line and a 220kV substation to connect Solomon and Eliwana.

The transmission line and substation will be used to electrify Eliwana’s mining fleet with the grid connection allowing the mine to receive renewable energy by the end of 2025.

Transition to Battery System Haul Trucks

In March 2022, Fortescue acquired Williams Advanced Engineering (WAE), giving the company critical technology and expertise in high-performance battery systems and electrification.

The acquisition enables the company to develop the zero emission battery solutions needed to decarbonise its mining fleet.

“Last year, we deployed our first battery electric haul truck prototype, Roadrunner, to our Christmas Creek operations for site-based testing,” Ms Forster said.

“Integrated with a 1.4MWh prototype power system, Roadrunner is the only surface mining truck capable of fast charging in 30 minutes and storing regenerated power as it drives downhill.

“As part of this testing, we are gaining insights that will be incorporated into our future zero emissions haul truck fleet.”

Fortescue plans to have its first battery electric production trucks operational in the Pilbara during 2026.