RaptorTech’s Next Generation Fleet Management and Collision Avoidance Technology Set to Revolutionise Mining Operations

Jean Ferreira (left) and Aaron Locke, (founders of RaptorTech) at a recent commissioning of a Raptor Data Centre, an independently powered mine-wide private LTE (4G) network.From the distant echoes of 17th century experiments to the pulsating digital realms of today, telemetry has etched its mark on the annals of innovation. Its story is one of relentless evolution, fuelled by human ingenuity and the quest for remote connectivity. Imagine early scientists tinkering with rudimentary forms of remote communication, laying the groundwork for what would become the backbone of modern telemetry. Fast forward to the tumultuous battlegrounds of World War II, where telemetry emerged as a silent sentinel, guiding weapons systems and tracking missiles with unparalleled precision. Then came the space age, where telemetry became the lifeline of astronauts, bridging the gap between Earth and the cosmos.

As the 20th century unfolded, advancements in electronics propelled telemetry into new frontiers, empowering industries from aerospace to medicine with real-time data transmission and control. With the dawn of the digital revolution, telemetry shed its mechanical shackles, embracing wireless communication and ushering in an era of unprecedented connectivity.

Looking into the future, the mining industry stands poised on the brink of a technological renaissance, leveraging the capabilities of telemetry to unlock new opportunities in efficiency and safety. Mines where every movement is monitored and optimised in real-time, where equipment maintenance is predictive rather than reactive, and where safety is not just a goal but a fundamental principle. This is the logical future that telemetry promises—a future where RaptorTech thrives on the cutting-edge of innovation, propelled by the transformative power of technology.

Nestled in Perth, Western Australia, amidst the bustling landscape of rugged terrain and rich mineral deposits, RaptorTech, a small mining technology business, has taken on the challenge of delivering solutions to the entire mining industry. They harness the potency of telemetry to reshape the landscape of fleet management and collision avoidance/prevention.

RaptorOS Fleet Management

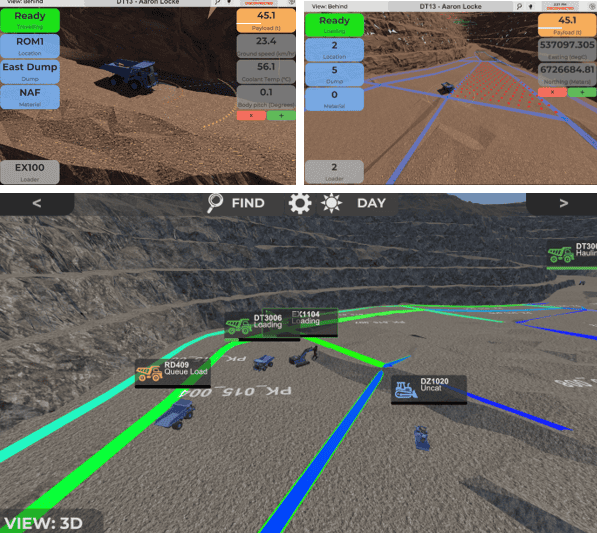

Enter RaptorOS Fleet Management Solution, a technological breakthrough that harnesses the power of telemetry to revolutionise fleet management, providing fully immersive, real-time insights and driving operational excellence. RaptorOS has been designed to help operations become safer, more productive, and more profitable. Real-time data can be pulled from virtually any mining or industrial machine, enabling exceptionally informed operational decision-making, material tracking, and production reporting.

Jean Ferreira, co-founder and director of RaptorTech, explained the benefits of its new fleet management and collision avoidance/prevention products and how the technology is presented in a suite of features designed to optimise efficiency, enhance safety, and maximise productivity.

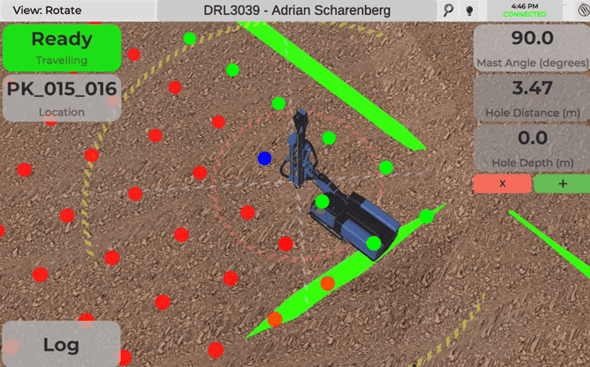

“RaptorCore, the telemetry platform central to our products, features an integrated HPGPS proximity awareness system that provides immersive safety awareness through real-time visualization of the 3D mine environment,” he said.

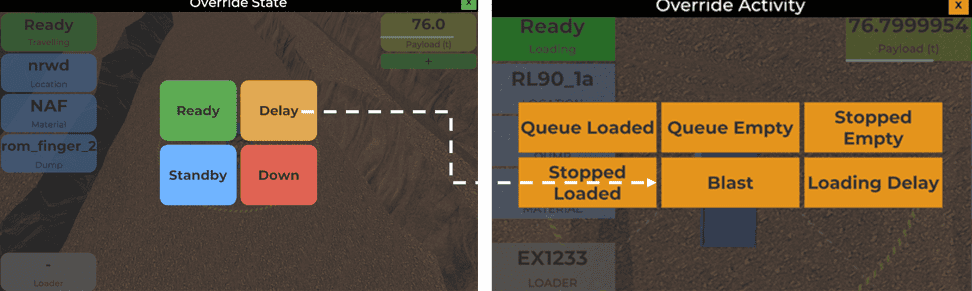

“Multi-sensor telemetry gives operators, supervisors, superintendents and management greater visibility over driving behaviour. Based on real-time values like speed, proximity, and gear selection, operators will receive alerts for any imminent failures. Operations will also benefit from full 3D spatial playback, which enables comprehensive incident investigation and review, as well as a traffic flow heatmap feature that identifies high-risk interaction zones, further improving safety protocols and accident prevention measures.”

From a productivity perspective, RaptorOS leverages automated activity categorisation using peer-to-peer, machine data, and GPS positioning, which can accurately identify operational metrics, enabling targeted improvements.

Mr Ferreira said that real-time payload monitoring between trucks and diggers optimises material handling, while its dispatch application empowers supervisors to closely monitor multi-digger fleet performance and achieve targets.

“The standby categorisation feature provides insights and key metrics around shift changes and break performance, which facilitates effective management strategies. We also offer real-time reporting of excavator tonnes per hour, hang time, drill-rate for drills, payload, queue time for trucks, and fleet cycle times. This granular level of performance tracking also allows quick identification of skills gaps and training needs at the operator or crew level.”

Profitability is another core driver that is addressed by the RaptorOS platform. “Our solution allows operators to extract more product at a lower cost through more precise digging and drilling applications,” said Mr Ferreira.

“Machine guidance features for excavators, dozers, wheel loaders, and drills are focused on optimising ‘mine to plan accuracy,’ while full integration with fleet management systems and safety functions streamlines workflows.”

“Our products feature user-friendly interfaces with less clutter in the cab, consolidating multiple functions onto a single screen for ease of use,” added Mr. Ferreira. “Real-time identification of material types from design files further enhances operational efficiency, and our hoist interlock feature prevents material being dumped in the wrong locations, reducing costly errors and increasing overall profitability.”

Collision Avoidance Systems and Their Impact on Mining Operations

The implementation of collision avoidance systems has played a critical role in increasing efficiencies and profitability of mining operations. These systems enable sites to operate autonomously, which in-turn, lowers operating costs by streamlining personnel requirements and related costs.

“As collision avoidance technology has improved and matured, it has also allowed operations to increase daily running hours for improved efficiencies,” said Mr Ferreira.

“However, the key benefit that sites have seen from autonomous haulage systems and collision avoidance systems has been the significant improvement in safety. There have been fewer PFI’s linked to manually operated fleets by removing human error from the decision-making process.”

Mr. Ferreira added that functional safety redundancy is the real stand-out feature of Percept collision avoidance/prevention.

“Well before progressing to the benefits of an autonomous haulage fleet, our objective is zero vehicle/vehicle interactions and zero vehicle/personnel interactions. The Percept system offers four levels of functional safety, stereo vision, radar, peer-to-peer, and high precision GPS. Percept auto provides the LVL9 braking intervention. The system can be retrofitted to almost any piece of equipment and is OEM agnostic. The Immersive 3D visualization enables virtual mine drives for a realistic experience, and the real-time alerts keep operators and supervisors informed, improving their situational awareness,” he said.

“Historical playback supports incident investigation and facilitates post-event analysis. Additionally, the traffic flow heatmap identifies interaction risk zones, allowing for proactive risk management strategies.”

The importance of collision avoidance/prevention cannot be overstated.

“The South African Department of Mineral Resources has legislated that ALL mining equipment be fitted with LVL9 collision avoidance capability and failure to comply could result in operations being suspended. Like seatbelts in a motor vehicle, this safety measure is inevitable in the mining industry, and there are numerous countries considering their position in this regard,” said Mr Ferreira.

A Technology as a Service (TaaS) Model Approach

Now, in a world of ever-increasing costs, the race to zero emissions, and accessing lower-grade mineral deposits for raw materials needed to make green energy power generation, every last ounce of productivity must be squeezed out of an asset’s fleet. This relies heavily on accurate data to drive more informed decision-making.

“Our TaaS model helps mining operations become more integrated and cost-efficient,” said Mr Ferreira.

“We see existing technology products as capital intensive (both directly and for supporting infrastructure); however, our solutions use a TaaS model, which is designed from the ground up as a zero CAPEX solution. This consists of FMS, communications, and HPGPS, all in a single package, priced as a monthly subscription.

“Essentially, we make cutting-edge technology accessible to every mining operation. But importantly, solutions that are cost-effective, scalable, and seamlessly integrated, and easily deployed.”

Traditionally, mining has been fraught with labour-intensive tasks and inherent risks. However, RaptorTech is reshaping this narrative by leveraging telemetry’s ability to remotely measure and transmit crucial data, thereby enhancing safety and streamlining operations. Through RaptorOS and Percept, RaptorTech encapsulates the essence of telemetry, revolutionising how mining operations are managed and executed.

For more information on RaptorTech’s suite of industrial solutions, email [email protected] or visit www.raptortech.com.au/