AusIMM’s parallel conference debut

The Life of Mine | Mine Waste and Tailings Conference 2025, on July 29-30, saw two of the resource sectors most influential events run side-by-side in a first of its kind dynamic two-day event.

AusIMM’s collaboration with The University of Queensland’s Sustainable Minerals Institute bought together global mining professionals, researchers and industry leaders to connect and collaborate.

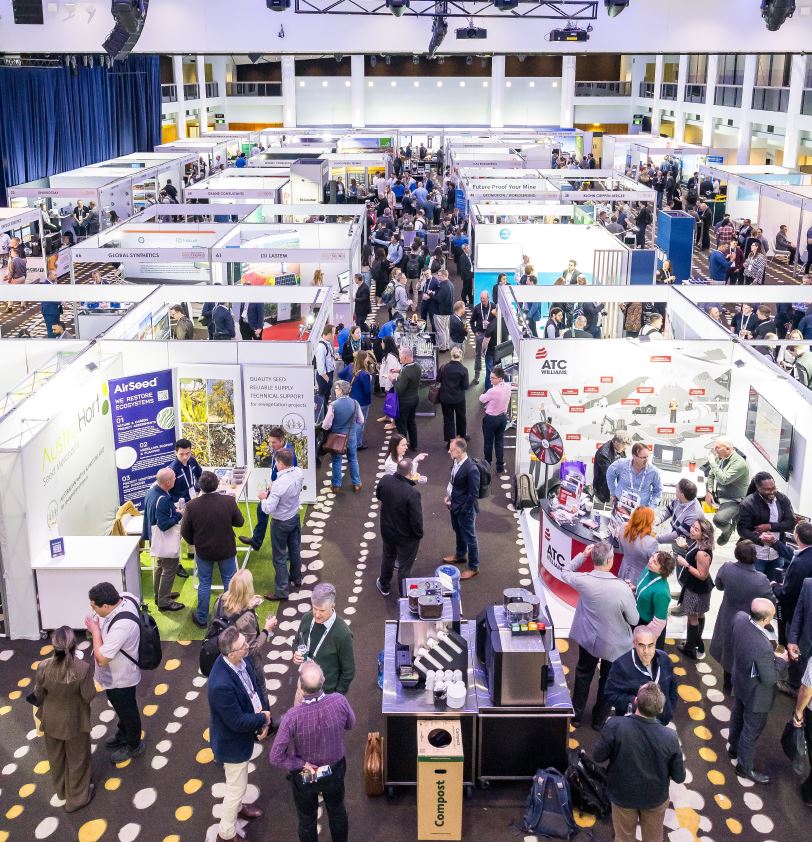

Hosted at the Brisbane Convention and Exhibition Centre, the conference presented a broader scope and increased opportunities for knowledge sharing and collaboration amongst delegates by combining two established audiences.

Delegates no longer had to choose between mine lifecycle planning or waste management topics, as this event combined the best of both worlds. The combined conference prioritised core essentials including practical, real-world solutions and sustainable practices addressing key themes such as responsible mine lifecycle planning, decarbonisation and waste management.

The united platform provided an expanded technical program and access to professionals involved in every aspect of mine development, sustainability, waste management and environmental responsibility, fostering long term resilience within the mining industry.

With a legacy built over six successful iterations, the Life of Mine Conference focused on responsible, end-to-end planning for mining projects. With its unique holistic coverage of topics including regional rehabilitation, circular economy integration, decarbonisation and effective regulatory frameworks, the event attracted industry professionals and creates an essential forum for advancing sustainable operations.

AusIMM’s Mine Waste and Tailings Conference, launched in 2015, quickly established itself as the industry’s premier event for advancing safe and compliant waste management practices. Exploring themes of risk assessment, tailings dam management, stakeholder engagement and post-closure site monitoring the event attracted a highly engaged and specialised audience.

The unified event showcased a comprehensive platform, covering a broad spectrum of critical topics including dewatering, social performance, regional collaboration and biodiversity investments.

ICMM data and researcher director Emma Gagen says she was very pleased to see the Mine Waste and Tailings and Life of Mine conferences running in parallel.

“The Life of Mine Conference focuses on closure, and when it comes to integrated closure there’s no more complex domain on a site than a tailings storage facility,” she said.

“This is the place where we should see the cross-pollination of ideas that could unlock one of the critical challenges for both closure and tailings practitioners.”

The program featured 110 oral presentations across the two conferences, seven panel discussions, three keynote presentations and 66 organisations.

There were 12 nations represented throughout the program, indicating the strong international interest and involvement in the dual event.

Delegates heard insightful keynotes, thought-provoking panel discussions and fantastic presentations across two action-packed conference streams. There was also plenty of time for connection and networking in the breaks in the buzzing exhibition hall.

Keynote speakers

Dr Gagen, an industry leader in mine rehabilitation, delivered a keynote backed by her extensive first-hand experience — Simplifying the mining standards landscape.

The University of Queensland Centre for Social Responsibility in Mining director Deanna Kemp, a leading international expert focused on the social and political challenges of the global mining industry, delivered the opening keynote on day two of the event.

WSP senior vice president and geotechnical engineer Christopher N. Hatton and The University of Queensland Geotechnical Engineering Centre director David Williams used their more than 80 years of combined industry experience to present a keynote on tailings management.

“Tailings dam design, for all practical purposes, is a guess,” Mr Hatton said.

“It’s an educated guess — but still a guess.

“We spend the entire period of constructing the dam verifying that our guess was correct.”

Mr Williams offered a global perspective, focusing on notable tailings management failures and the systematic changes that resulted.

Describing the 1965 El Cobre disaster in Chile, that resulted in more than 200 fatalities, as a turning point in the industry. Mr Williams says though it was a tragedy, it spurred real change.

“The industry banned upstream dam construction in seismic zones long before regulators did,” he said.

“They moved from two-to-one slopes to four-to-one. That doubled the margin of stability.”

Mr Williams then flipped the focus to the fragility of governance in tailings management that was exposed by the more recent Samarco disaster in 2015 and Brumadinho in 2019. Both failures, located in Brazil, resulted in flooding that devastated downstream villages and infrastructure and killed nearly 300 people.

“Brumadinho was different. It wasn’t just a Brazilian failure — it was a global one,” he said.

“That tells you the pressure isn’t just coming from engineers anymore. It’s coming from markets and shareholders.”

Both Mr Williams and Mr Hatton highlighted the financial fallout that the responsible companies experienced due to their oversight.

“They nearly didn’t survive, the reputational damage was immense,” Mr Williams said.

“These weren’t just engineering failures — they were corporate catastrophes.”

In closing, both speakers advocated for the prioritisation of simple and stable structures that work.

“Stay true to the science, don’t build in layers of conservatism without justification,” Mr Hatton said.

“That doesn’t help the industry — it distorts reality and drives bad decisions.”

Panel discussions

Key players exchanged ideas on important topics at the conference panel discussions.

On day one of the event, the presentation titled Beyond the Mine: Strategies for Thriving, Sustainable Communities opened the series of panels.

In a panel titled Insights, successes and improvement opportunities: implementing and assuring the Global Industry Standard on Tailings Management (GITSM), key learnings and a view to the future on topics including risk management, safe closure, corporate governance and ongoing assurance were explored.

Topsoil deficits and establishment of growth media suitable for vegetated post mining land uses are a major ongoing challenge which poses difficult questions requiring innovative solutions. Bringing together industry leaders and experts to share their knowledge on managing such deficits, the Challenges with managing topsoil deficits for mine rehabilitation panellists divulged their firsthand experience addressing these challenges.

With more than 900 delegates in attendance, this new side-by-side conference experience provided some great moments, valuable insights and a unique cross-pollination of ideas to unlock new solutions in the industry.

AusIMM thanked the delegates, sponsors, exhibitors, presenters, committee members and staff that made this event such a resounding success.