The industry leader in OTR and LME tyre management

Since 1972, Otraco International has helped customers across the mining sector move more with less by increasing productivity and reducing the total cost of tyre ownership.

A wholly owned subsidiary of Bridgestone Mining Solutions Australia, Otraco has more than 50 years of experience in off-the-road (OTR) and light mobile equipment (LME) tyre management.

Today, Otraco’s team of more than 600 employees delivers onsite tyre management to more than 40 mining operations across Australia, New Zealand and Chile.

Its expert team is supported by accredited training programs, innovative technology solutions, tyre bay tooling and consumables supply, and consulting services.

Committed to safety and with innovation at its core, teams work within Otraco’s Safety First Always framework across all operations worldwide.

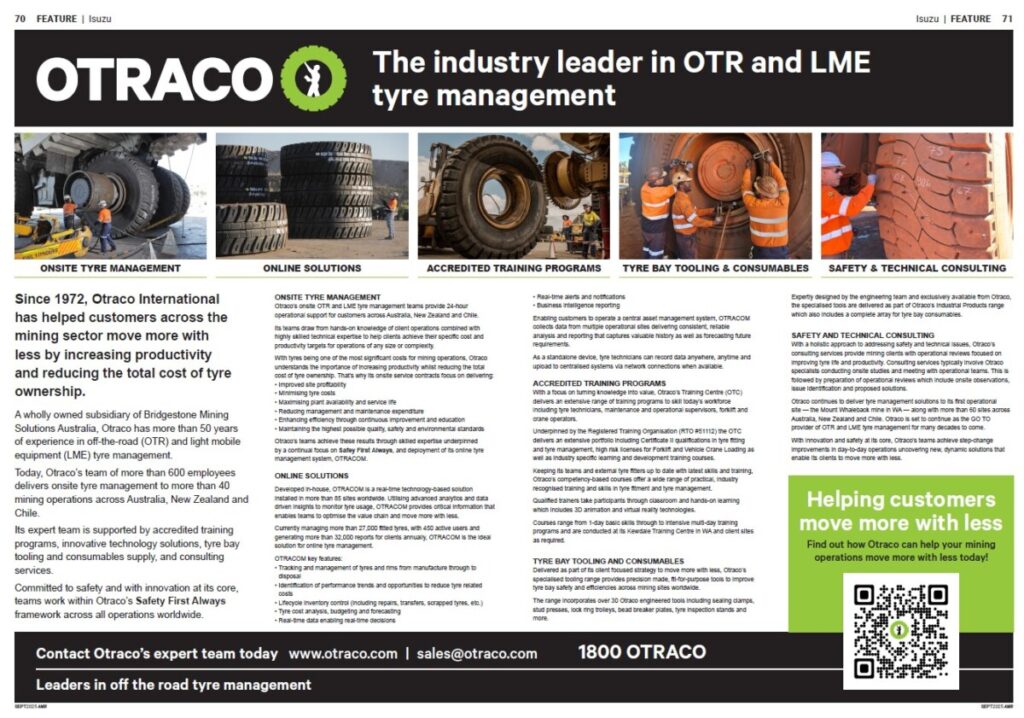

Onsite tyre management

Otraco’s onsite OTR and LME tyre management teams provide 24-hour operational support for customers across Australia, New Zealand and Chile.

Its teams draw from hands-on knowledge of client operations combined with highly skilled technical expertise to help clients achieve their specific cost and productivity targets for operations of any size or complexity.

With tyres being one of the most significant costs for mining operations, Otraco understands the importance of increasing productivity whilst reducing the total cost of tyre ownership. That’s why its onsite service contracts focus on delivering:

- Improved site profitability

- Minimising tyre costs

- Maximising plant availability and service life

- Reducing management and maintenance expenditure

- Enhancing efficiency through continuous improvement and education

- Maintaining the highest possible quality, safety and environmental standards

Otraco’s teams achieve these results through skilled expertise underpinned by a continual focus on Safey First Always, and deployment of its online tyre management system, OTRACOM.

Online solutions

Developed in-house, OTRACOM is a real-time technology-based solution installed in more than 85 sites worldwide. Utilising advanced analytics and data driven insights to monitor tyre usage, OTRACOM provides critical information that enables teams to optimise the value chain and move more with less.

Currently managing more than 27,000 fitted tyres, with 450 active users and generating more than 32,000 reports for clients annually, OTRACOM is the ideal solution for online tyre management.

OTRACOM key features:

- Tracking and management of tyres and rims from manufacture through to disposal

- Identification of performance trends and opportunities to reduce tyre related costs

- Lifecycle inventory control (including repairs, transfers, scrapped tyres, etc.)

- Tyre cost analysis, budgeting and forecasting

- Real-time data enabling real-time decisions

- Real-time alerts and notifications

- Business intelligence reporting

Enabling customers to operate a central asset management system, OTRACOM collects data from multiple operational sites delivering consistent, reliable analysis and reporting that captures valuable history as well as forecasting future requirements.

As a standalone device, tyre technicians can record data anywhere, anytime and upload to centralised systems via network connections when available.

Accredited training programs

With a focus on turning knowledge into value, Otraco’s Training Centre (OTC) delivers an extensive range of training programs to skill today’s workforce including tyre technicians, maintenance and operational supervisors, forklift and crane operators.

Underpinned by the Registered Training Organisation (RTO #51112) the OTC delivers an extensive portfolio including Certificate II qualifications in tyre fitting and tyre management, high risk licenses for Forklift and Vehicle Crane Loading as well as industry specific learning and development training courses.

Keeping its teams and external tyre fitters up to date with latest skills and training, Otraco’s competency-based courses offer a wide range of practical, industry recognised training and skills in tyre fitment and tyre management.

Qualified trainers take participants through classroom and hands-on learning which includes 3D animation and virtual reality technologies.

Courses range from 1-day basic skills through to intensive multi-day training programs and are conducted at its Kewdale Training Centre in WA and client sites as required.

Tyre bay tooling and consumables

Delivered as part of its client focused strategy to move more with less, Otraco’s specialised tooling range provides precision made, fit-for-purpose tools to improve tyre bay safety and efficiency across mining sites worldwide.

The range incorporates over 30 Otraco engineered tools including sealing clamps, stud presses, lock ring trolleys, bead breaker plates, tyre inspection stands and more.

Expertly designed by the engineering team and exclusively available from Otraco, the specialised tools are delivered as part of Otraco’s Industrial Products range which also includes a complete array for tyre bay consumables.

Safety and technical consulting

With a holistic approach to addressing safety and technical issues, Otraco’s consulting services provide mining clients with operational reviews focused on improving tyre life and productivity. Consulting services typically involve Otraco specialists conducting onsite studies and meeting with operational teams. This is followed by preparation of operational reviews which include onsite observations, issue identification and proposed solutions.

Otraco continues to deliver tyre management solutions to its first operational site — the Mount Whaleback mine in WA — along with more than 60 sites across Australia, New Zealand and Chile. Otraco is set to continue as the GO TO provider of OTR and LME tyre management for many decades to come.

With innovation and safety at its core, Otraco’s teams achieve step-change improvements in day-to-day operations uncovering new, dynamic solutions that enable its clients to move more with less.