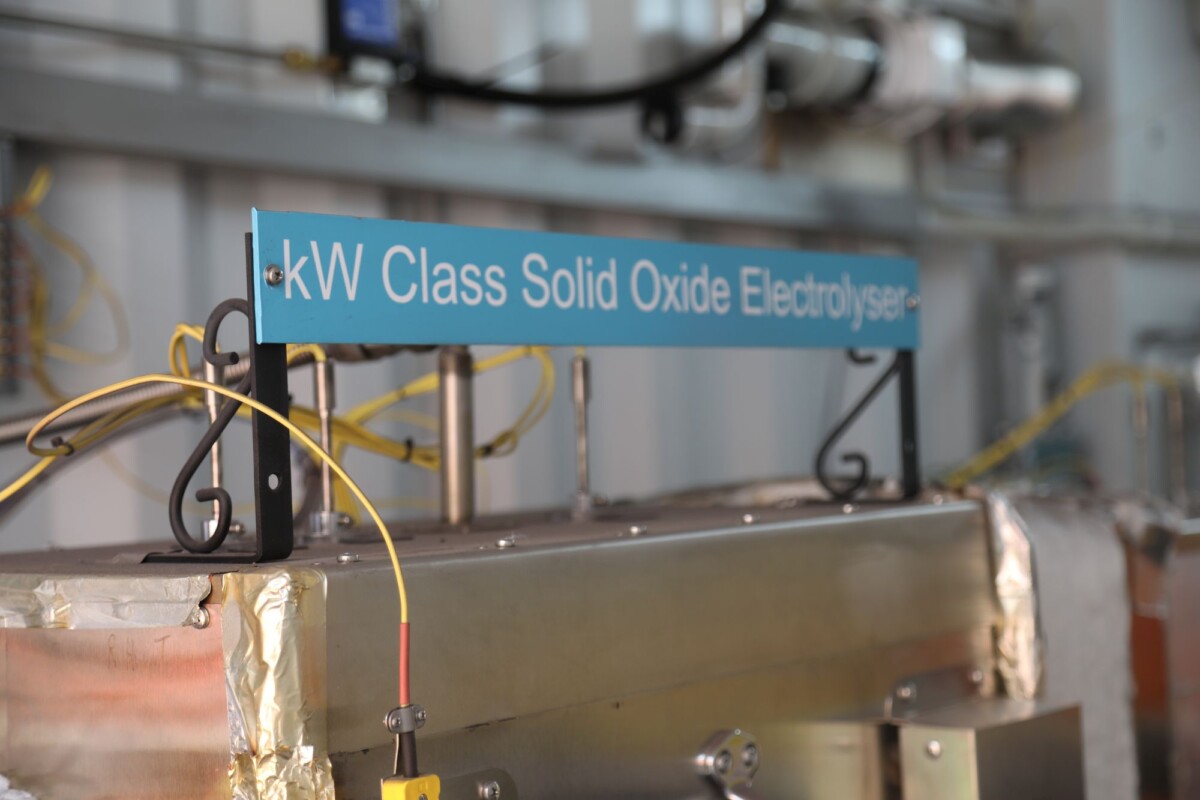

BlueScope low-carbon steel with CSIRO electrolyser

CSIRO has successfully trialled its innovative hydrogen production technology at BlueScope’s Port Kembla Steelworks in NSW, proving that affordable and renewable hydrogen can be generated at scale to help decarbonise heavy industry.

The trial commenced in October 2024 and features the national science agency’s tubular solid electrolysis (SOE) technology, which has clocked 1000 hours of successful operation turning both waste heat and electricity into hydrogen – with much greater efficiency than traditional methods.

Conventional hydrogen electrolysers rely heavily on electricity to split water into hydrogen and oxygen.

CSIRO senior principal research scientist and group leader Dr Sarb Giddey says the trial produced hydrogen with an electrical input of less than 36kWh per kilogram of hydrogen, by using the steam produced in the plant by the steelmaking processes.

“Since electricity takes up the lion’s share of variable production costs for renewable hydrogen, a substantial reduction in the electricity required (up to 30% saving) for hydrogen production could be a game changer for the nascent hydrogen industry.

“Taking a new technology out of the lab and into the field can highlight unforeseen challenges, so we are delighted to see that our technology is meeting the performance requirements in terms of hydrogen production, electrical efficiency and reliability.”

BlueScope head of future technologies Chris Page says hydrogen is an important part of the company’s pathway to net zero.

“BlueScope is proud to support pilot projects on site, which align with our goals of low carbon emission steelmaking in the future,” he said.

“The CSIRO electrolyser pilot has produced positive outcomes in its short-term operation, and we look forward to seeing it evolve.”

CSIRO spinout Hadean Energy has licensed the agency’s SOE technology and is on a mission to accelerate industrial decarbonisation.

Hadean Energy chief executive Chris Rowland says the tubular SOE technology has a further advantage of being inherently less expensive to build because of the simplified manufacturing process and more readily available materials.

“The 1000-hour milestone validates the technology in a real-world industrial setting, increasing the technology readiness level to prepare for commercialisation,” he said.

“It shows the potential for Hadean Energy’s electrolyser to decarbonise hard-to-abate industries.”

This research is supported by the Science and Industry Endowment Fund.

While CSIRO is trialling the tubular SOE electrolyser in the field with BlueScope, Hadean Energy is testing the long-term durability and performance of the modular design at CSIRO’s Hydrogen Technology Demonstration Facility.

Following these successful trials, Hadean Energy is preparing to showcase a 5kW demonstration unit as part of the Australia-UK Renewable Hydrogen Innovation Partnerships.

This will serve as a stepping stone toward a large-scale industrial pilot, positioning Hadean Energy as a leading global clean hydrogen technology provider.