Fortescue backed pilot plant makes debut

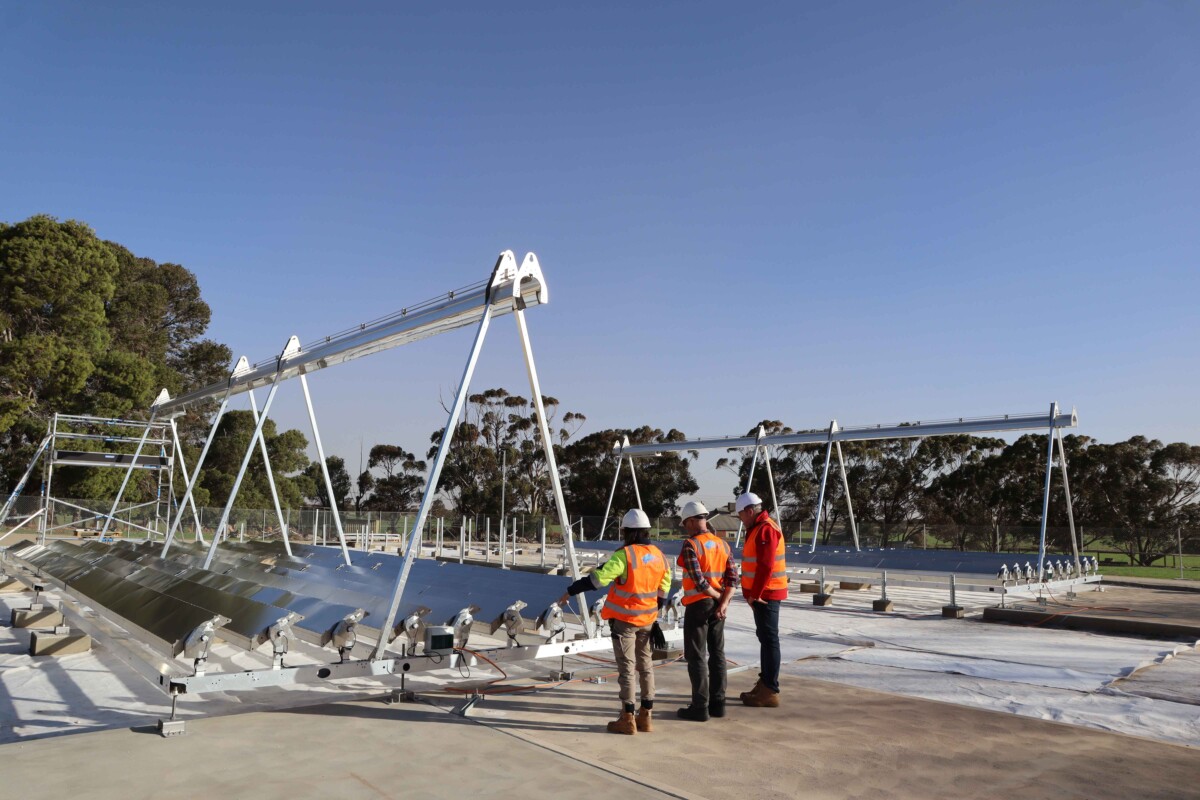

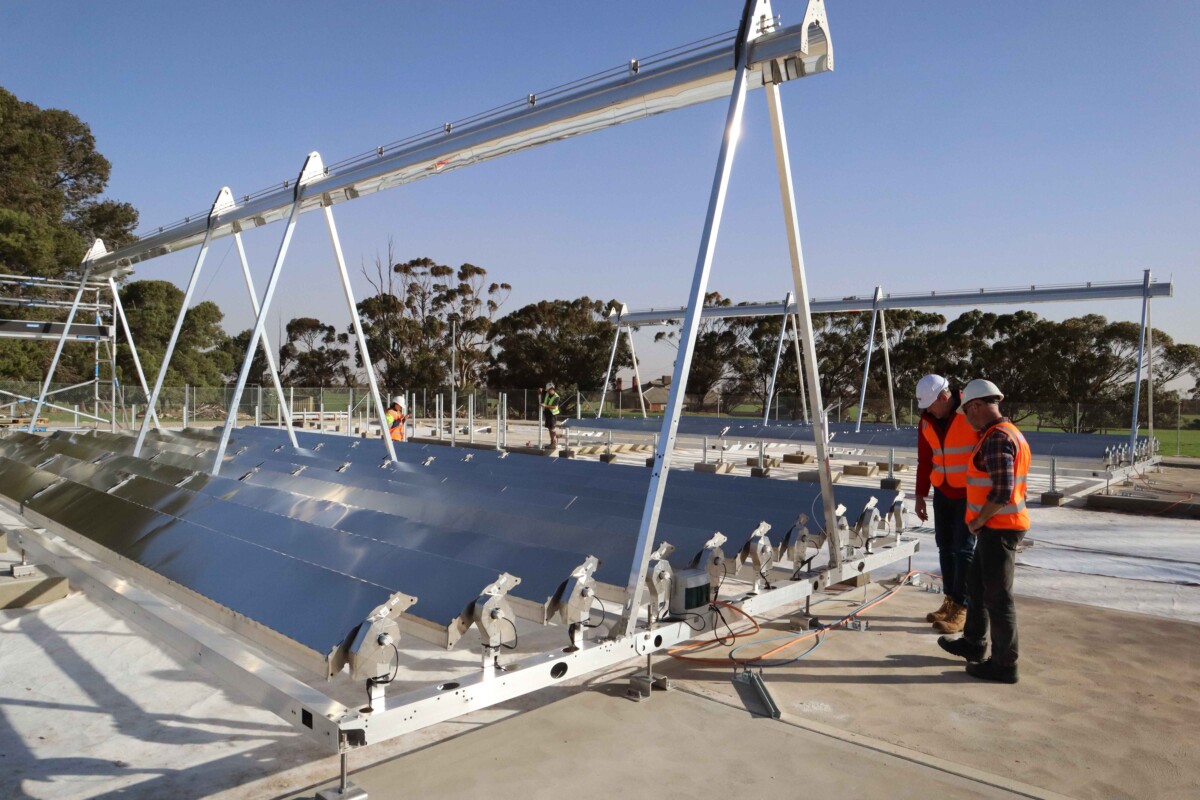

Sparc Hydrogen has launched a pilot plant using first of its kind green hydrogen reactor technology at the University of Adelaide in South Australia.

The company is a joint venture between Fortescue (ASX: FMG), Sparc Technologies and the University of Adelaide founded to translate research conducted at the university.

The Sparc Hydrogen Advanced Research Pilot (SHARP) is a test bed for photocatalytic water splitting (PWS), a process which harnesses solar to extract green hydrogen from water.

The method, unlike traditional processes, does not require electrolysers powered by electricity — a potential game-changer in delivering low-cost renewable hydrogen.

SHARP will accelerate the development of the patented reactor technology and enable real-world evaluation of PWS catalysts being developed globally.

University of Adelaide research deputy vice-chancellor professor Anton Middleberg says Sparc Hydrogen demonstrates how the university is working with industry partners to develop new pathways for the translation of world-class research conducted here in South Australia.

“This project aims to respond to one of the great challenges of our times — the development of green energy solutions for a sustainable future for society,” he said.

PWS is commonly referred to as direct solar-to-hydrogen technology as it avoids the need to convert solar energy into electricity to split water via electrolysis. In photocatalysis, the sun’s energy is directed onto a highly specialised photocatalyst material, which forms reactive sites that splits water into hydrogen and oxygen without electrolysis.

Despite decades of research and notable advancements, the efficiency of PWS remains a key challenge to reaching commercialisation. The SHARP pilot plant aims to improve the economics of producing green hydrogen using PWS through driving increased efficiencies within modular and scalable concentrated solar infrastructure.

Sparc Hydrogen acting director professor Greg Metha says the plant will allow the team to independently and concurrently test different reactor designs and photocatalyst methods.

“This next-generation photocatalytic water splitting technology has major advantages over electrolysis as it offers the potential to produce low cost, scalable green hydrogen and heat without significant electricity use,” he said.

In the lead up to commissioning of the plant, front-end engineering and design was undertaken by leading global engineering and commercial service provider Incitias.

The Sparc Hydrogen’s photocatalytic water splitting reactor, which is being commissioned using photocatalysts developed by Shinshu University in Japan, was developed at the University of Adelaide’s School of Physics, Chemistry and Earth Sciences.

Fortescue R&D director Michael Dolan says the company is investing in a suite of technologies that can accelerate decarbonisation at an industrial scale.

“The SHARP pilot demonstrates the power of partnership in pushing the boundaries of green hydrogen innovation,” he said.

“Photocatalytic water splitting has long held promise and this project is a step toward unlocking its commercial potential.”