Krux of the matter: more metres for your dollar

IMDEX-Krux partnership set to improve productivity in exploration and production drilling.

Increasing Productivity in Exploration and Production Drilling

A partnership between leading global mining-tech company IMDEX and drilling analytics market leader Krux is driving a digital transition to improve productivity in exploration and production drilling.

With recent figures revealing a reduction in metres drilled despite record mineral exploration spending, IMDEX and Krux say it is time for the mining industry to embrace technology that will deliver better outcomes.

IMDEX chief executive Paul House says the Australian Bureau of Statistics (ABS) figures for the June quarter shows a reduction in metres drilled against a June spending record of $1.069b, revealing the productivity gap facing the mining industry.

While the figures were for Australia, the same cost pressures were present in other countries, he said.

IMDEX took a 40% interest in Krux earlier this year.

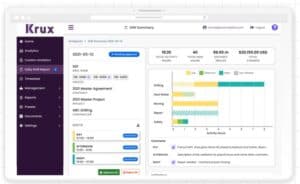

Krux collects and analyses exploration and production drilling data in near real time.

Founder and chief executive Jody Conrad says Krux’s software is central to solving the productivity challenge.

“We definitely fill that productivity gap,” she said. “Our goal is to get you as many metres as possible.”

Ms Conrad said a combination of technology and innovation meant it was now cost effective to make the digital transition.

Together, IMDEX and Krux have the software and tools to collect and analyse the increasing streams of data from digital drill rigs.

The History Behind Krux

A mechanical engineer who built and designed automated drilling rigs for the oil and gas sector, Ms Conrad founded Krux in 2016 to marry real-time drilling analytics with financial data to optimise drilling operations.

The plan was to target the oil and gas sector.

Instead, Krux found itself solving the same problem in the mining sector, ending the need for spreadsheets and manual data entry, and resolving time delays, inefficiencies and inconsistencies caused by trying to compare separate data sets, contracts and financial statements.

“It was an onerous, manual process,” Ms Conrad said.

“There was never a reconciliation in the old process.

“Someone might have entered the operational data and done analysis but the two would be sitting separately.

“The number one thing we do is bring all the data together so you can understand what’s costing you money and what’s producing your metres so you can optimise your operations.

“It’s vital that there is a single source of data.

“That’s the problem, or the crux of the matter, that we solved.”

Developing a Global Solution

Mr House said that in time Krux software would replace the IMDEX Mobile product and provide a clear pathway for customers to receive a best-in-class solution.

Krux’s strong market position in North America, combined with IMDEX’s strength in the Asia Pacific and Africa, presented the opportunity to develop a global solution.

Ms Conrad says the migration of IMDEX Mobile customers to the Krux platform is progressing well.

“More than 80% of customers are in conversations with us,” she said.

“Our platform is currently on over 600 rigs worldwide, but the potential market is more than 4000 rigs.”

One of the benefits of the Krux software is that data is normalised, allowing for meaningful comparisons of drilling campaigns.

“Regardless of who is drilling or which mining company, our data goes into a normalised system so that if I’m a mining company with operations in Australia, Canada and the US I can normalise all those operations to say how is the US doing compared with Canada or how is the drilling performance different between these rigs or how are my costs different,” Ms Conrad said.

“The transparency is the key to driving better results.

“Mining clients want to reduce their costs, but they don’t mind as much if they are drilling more metres.

“For drillers, at the end of the day they are trying to drill as many metres as possible for their client and there is a budget.

“If we can optimise their drilling, then they get work next year.

“What driller wants to sit on standby and get a lower rate from the mining client because their drilling program took longer than expected and was disrupted, rather than get the higher metreage rate.

“The interactive process is the benefit we have over our competitors. It’s the approval and validation, a single source of data for all decisions.

“Others take data from multiple sources and provide it for analysis.

“That’s one step up from a spreadsheet.

“We take the data to the next level.

“It’s approved and validated; everyone has access, and everyone is on the same page.”