Coerco critical for major clean energy and eco-friendly water management projects

The Kidston Hydro Project is a clear example of how government led incentives programmes have helped to drive investment towards cleaner energy projects.

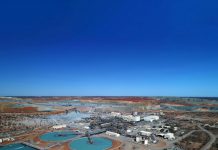

The 250MW Kidston Pumped Storage Hydro Project in Queensland’s north received support from the Northern Australia Infrastructure Facility (NAIF) in aloan worth up to $610 million, in addition to a $47 million grant from the Australian Renewable Energy Arena (ARENA).

The funds helped Genex Power Limited build the first pumped storage hydro project in Australia since 1984 and the first to be used solely for energy storage and generation rather than water management.

A key part of the project involved the dewatering of an abandoned gold mine, about 400km inland from Townsville, a challenge taken on by West Australian based Coerco.

COERCO, widely known for manufacturing industry-leading poly tanks, has successfully expanded its capabilities since it was founded more than 30 years ago.

Its broad range of solutions can now be divided into three main divisions: contain; float; and, move.

The remoteness of the location coupled with difficulties accessing the site required COERCO to draw upon its experience and expertise to solve numerous problems.

Due to the difficulties involved with entrance to the water body in the former mining pit, there were major safety in design considerations to ensure that most importantly the personnel, but also the equipment involved with this scope were safeguarded.

COERCO head of projects Warren Classen says the logistical challenges continued, as COERCO was required to transport large equipment over difficult terrain and long distances.

COERCO head of projects Warren Classen says the logistical challenges continued, as COERCO was required to transport large equipment over difficult terrain and long distances.

“One major factor we needed to take into account was transportability to get it to site, the assembly of the system, and then launching it into the dam,” Mr Classen said.

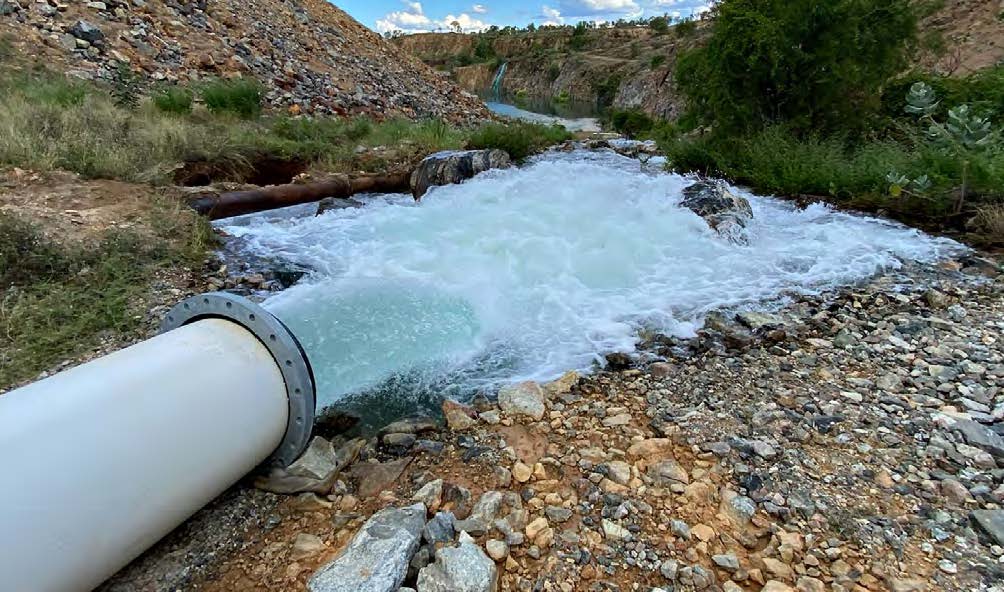

The Kidston Hydro Project, led by construction contractor McConnell Dowell – John Holland (MDJH JV), would ultimately involve moving 30 gigalitres of water from the Eldridge Pit into the new Wises Dam.

COERCO designed and assembled a modular system that consisted of 6 pumps with 850kw motors, allowing a flow rate of 200 litres per second, per pump, or 1200 litres per second for the system.

Will Hefferan, surface works area manager for the project, said COERCO responded well to the challenges.

“It’s been really easy working with COERCO,” Mr Hefferan said. “Whenever I need some information from them, they’re easily accessible to call or chat with or send an email through and receive the information.

“If I had a job requiring a similar solution, I’d like to seek a solution from them. “It’s been very enjoyable working with COERCO, and as you can see with the solution we’ve got there, it all came to fruition pretty well,” Mr Hefferan said.

COERCO has had extensive experience working on major dewatering projects and the company has developed fruitful and long-lasting industry partnerships along the way. Aqua Energy Group design, supply, install, commission and maintain water and slurry packaged pump systems and electrical equipment for major mines in Australia.

Aqua Energy Group has earned a reputation within the mining industry for dealing with the most complex and challenging projects, particularly when it comes to integrated pump systems.

Daniel Thompson, project director at Aqua Energy Group, is well aware of the many complexities that exist when it comes to liquid management in the mining industry.

“When faced with a complex project, many considerations are at play, including the

liquids and site applications involved, the type of pontoon selected, and of course the pumping system required to effectively manage different liquids,” Mr Thompson said.

“Add to this a multitude of other factors and complexities within a project, and it’s no surprise that it takes a unique set of skills to deliver a practical, cost-effective solution.

“We have completed a significant number of projects over the years, from small pump stations to large turnkey projects such as containerised fire pumps and pontoon pump stations, dewatering operations and waste water treatment plants.

“Our pumping and electrical solutions are on show across multiple industries including mining, fire, civil, renewable, and tunnelling, with projects including mine sites, municipal projects, renewable hydro power plants, and industrial sites.”

It is difficult to discount the value of a collaborative partnership.

This is particularly evident in projects that face time pressures on designs that require integration of liquid management products, or unique expertise from different industries as a single point of contact, to facilitate a holistic approach to the project.

As the industry’s liquid control specialists, COERCO understand the mutual benefits a collaborative approach and long-term partnership with industry experts such as Aqua Energy Group can provide.

With COERCO designing and supplying floating pontoons and Aqua Energy Group building pumping systems for projects all around the country, the alliance has successfully completed numerous challenging projects.

Mining and water infrastructure industries utilise pontoons and floating walkways to support heavy pumping equipment or machinery during floating applications.

Floatation on liquid, specifically industrial pump pontoons, is a specialised area where COERCO excel.

“Knowing COERCO’s extensive experience in pontoon design, and our capability from a pump system perspective, we leverage mutual expertise and resources that are second to none,” Mr Thompson said.

Controlling liquids with fit-for-purpose pontoons Dewatering is performed regularly in most open-pit and underground mining operations that are prone to flooding as a result of a shifting landscape and heavy rainfall.

As well as reducing flood risk and helping operations avoid shutdown, preventing toxic substances from leaking into nearby water or local ecosystems is a core function of pump pontoons which are used to drain excess water from mine tailings dams.

As well as reducing flood risk and helping operations avoid shutdown, preventing toxic substances from leaking into nearby water or local ecosystems is a core function of pump pontoons which are used to drain excess water from mine tailings dams.

A floating pontoon equipped with heavy pumping equipment is an ideal solution for miners when de-sludging and pumping effluent water from holding ponds.

It’s also suitable for reclaiming and cleaning shallow bodies of water or pits without heavy excavation and drainage.

Mine sites commonly use floating pontoons to provide a reliable platform when dredging pumps in high solid industrial pumping applications. They can also serve as stable access walkways for mining, or industrial floating operations in remote areas during floods.

COERCO have been building floating walkways and pontoons for decades. With many different styles, sizes and materials available, the type of pontoon depends upon the site requirements and type of environment in which liquids are being managed.

“When we work on a specific project with COERCO, we ensure the pontoon configuration and our pump system will function from a design point of view,” Mr Thompson said.

“Whether it’s a heavy-duty, lightweight poly, or modular setup, the type of pontoon makes a big difference to how we integrate the required pump system.

“The heavy-duty pontoons work really well for clients needing a robust, safe and stable platform capable of handling large pump setups and heavy loads of up to 25 tonnes.

“You’ve also got lightweight and versatile poly pontoons, ideal for tight spaces and temporary setups. These are manufactured using high-quality polyethylene materials, and are UV stabilised and resistant to corrosion and harmful chemicals.

“Then there’s the modular pontoons, which easily adapt and change your pontoon’s shape and size as your project requirements change. These can support a maximum load of 5 tonnes and are simple to assemble and reassemble as required.”

Coerco and Aqua Energy Group have partnered on a number of major mining projects, delivering solutions that aim to solve the most complex problems in liquid management.

They have leveraged their shared capabilities to achieve success in the areas of liquid containment, flotation on liquid, and liquid movement.

Two mine infrastructure projects the companies have worked on are based in the Moranbah region of Queensland, both of which were complex tailings management projects requiring a highspec engineered solution.

“The first project was for tailings storage management, which involved the design, supply and installation of all electrical and mechanical requirements,” according to Mr Thompson.

“We had two dual electric pontoons and custom walkways, two kiosk substations, and mine spec control panels, instrumentation, and electrical and pipework manifolds that were commissioned and integrated.

“The second complex tailings infrastructure project came off the back of a successful tender win for a flagship mining company. It involved a full turnkey solution from design to commission, and required a huge collaborative effort between ourselves and COERCO.”

COERCO is continuing to expand its network and involvement in the mining industry and will be attending the International Mining and Resources Conference (IMARC) in Sydney later this year.

The theme for the 2024 conference is:

“Accelerating the Critical and Responsible Pathway to Net Zero”.

COERCO will join others in the industry to learn more about strategies, expertise, and collaboration that will lead the industry toward a more sustainable future, at the Sydney International Convention Centre The event will be held from 29-31 October and is expected to be the biggest IMARC event yet, with record delegates, speakers, exhibitors, sponsors.

IMARC serves as a platform for industry, government, and community leaders from around the globe to engage in crucial discussions that will shape a sustainable and clean energy future.

“We take great pride in taking part in this significant event in the heart of Australia’s thriving metropolis, providing insights into the future of mining,” a COERCO spokesperson said.

“You can discover more of our efficient Mining Pontoon solutions and hear strategic ideas that will help lead to a more sustainable and greener energy future.

“With this, we hope to add value to your future projects.

“Coerco invites you to book a meeting with us ahead of time for an opportunity to have a productive discussion with our experienced team of Mining Pontoon specialists, as well as get fit-for-purpose solutions to suit your needs.”

For more information, visit https://www.coerco.com.au/