World-class material handling solutions

KOCH Solutions is your global partner for all your material handling requirements. With a heritage spanning more than 10,000 projects world-wide, KOCH Solutions has a thorough understanding of what truly matters in material handling.

The company offers an all-encompassing range of services, from designing and supplying to installing, operating, and servicing a vast array of material handling equipment. Whether you seek a reliable partner for a single project or require a long-term, full-scale solution provider — KOCH Solutions are equipped to elevate your operations.

Precision and reliability are at the core of KOCH Solutions’ operations, proven by its installed base track record and extensive expertise in operations and servicing. Backed by its commitment to first-class and lifelong service, KOCH Solutions is a dependable partner for the complete life cycle of material handling projects.

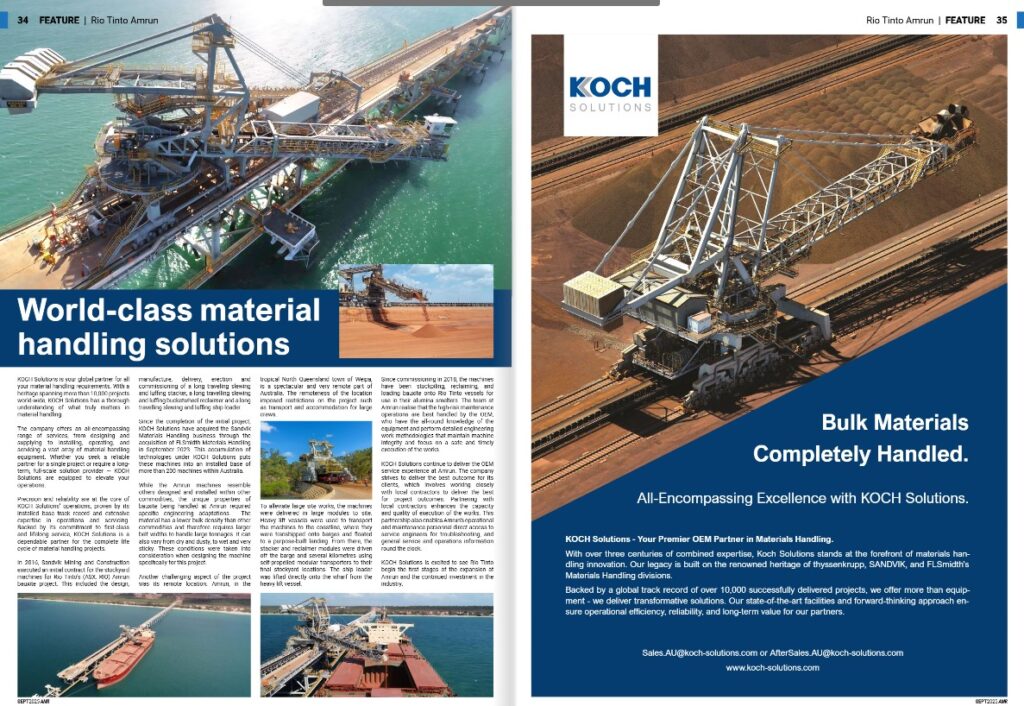

In 2016, Sandvik Mining and Construction executed an initial contract for the stockyard machines for Rio Tinto’s (ASX: RIO) Amrun bauxite project. This included the design, manufacture, delivery, erection and commissioning of a long traveling slewing and luffing stacker, a long travelling slewing and luffing bucketwheel reclaimer and a long travelling slewing and luffing ship loader.

Since the completion of the initial project, KOCH Solutions have acquired the Sandvik Materials Handling business through the acquisition of FLSmidth Materials Handling in September 2023. This accumulation of technologies under KOCH Solutions puts these machines into an installed base of more than 200 machines within Australia.

While the Amrun machines resemble others designed and installed within other commodities, the unique properties of bauxite being handled at Amrun required specific engineering adaptations. The material has a lower bulk density than other commodities and therefore requires larger belt widths to handle large tonnages. It can also vary from dry and dusty, to wet and very sticky. These conditions were taken into consideration when designing the machine specifically for this project.

Another challenging aspect of the project was its remote location. Amrun, in the tropical North Queensland town of Weipa, is a spectacular and very remote part of Australia. The remoteness of the location imposed restrictions on the project such as transport and accommodation for large crews.

To alleviate large site works, the machines were delivered in large modules to site. Heavy lift vessels were used to transport the machines to the coastline, where they were transhipped onto barges and floated to a purpose-built landing. From there, the stacker and reclaimer modules were driven off the barge and several kilometres using self-propelled modular transporters to their final stockyard locations. The ship loader was lifted directly onto the wharf from the heavy lift vessel.

Since commissioning in 2018, the machines have been stockpiling, reclaiming, and loading bauxite onto Rio Tinto vessels for use in their alumina smelters. The team at Amrun realise that the high-risk maintenance operations are best handled by the OEM, who have the all-round knowledge of the equipment and perform detailed engineering work methodologies that maintain machine integrity and focus on a safe and timely execution of the works.

KOCH Solutions continue to deliver the OEM service experience at Amrun. The company strives to deliver the best outcome for its clients, which involves working closely with local contractors to deliver the best for project outcomes. Partnering with local contractors enhances the capacity and quality of execution of the works. This partnership also enables Amrun’s operational and maintenance personnel direct access to service engineers for troubleshooting, and general service and operations information round the clock.

KOCH Solutions is excited to see Rio Tinto begin the first stages of the expansion at Amrun and the continued investment in the industry.