ACE: Fast. Safe. Unstoppable.

Good enough isn’t good enough when it comes to protecting your people.

In the absence of work-related injuries and illnesses between 2008 to 2018, Australia’s economy would have been $28.6b larger each year, according to a 2022 study by Safe Work Australia.

That’s why the Multotec team has reassembled — putting in the work to make its ACE screening panels safer and simpler so your crews go home safe, delivering projects on-budget and on-time.

ACE: new and improved

Over six months, the Multotec team focused on design enhancements that would improve safety and efficiency across applications.

Traditional screening panels can be ineffective and unsafe. Not only does this mean valuable product can be entirely missed, going right down the drain and never making its way to market, but your team also risks impact injuries and pinch points during installation.

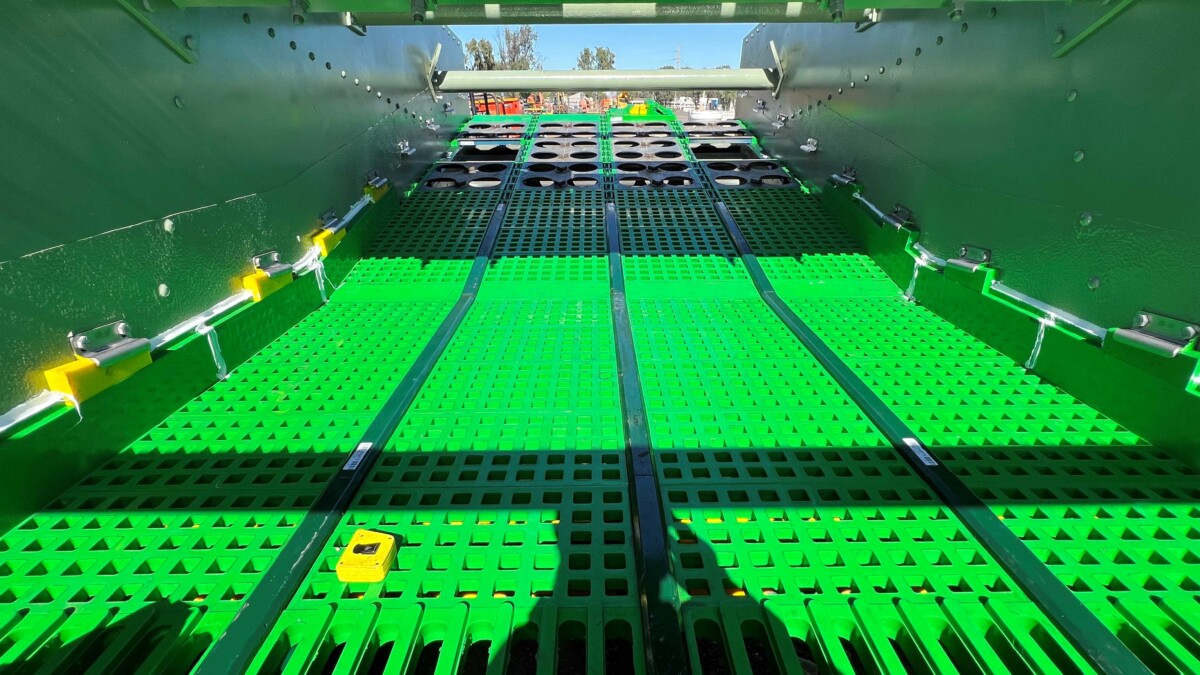

Originally introduced in 2019, the ACE system was developed to fill a critical gap in the market. Designed for fast, hassle-free installation, ACE maximises open area more effectively than traditional fastening systems.

Multotec undertook years of rigorous testing across various mineral types and international markets to ensure the ACE system is engineered for maximum performance, adaptability and simplicity that keeps profits high and your team safe.

Safe, easy and reliable

ACE is an ergonomic, safety-first design that protects your crew and speeds up installation.

The ACE solution requires zero hammers, meaning zero injury for your team.

ACE panels lock in place with just hand pressure so there is no impact risk and no pinch points. By reducing physical effort, it lowers the risk of strain or injury, creating a safer, more ergonomic work environment.

Once in place, ACE is engineered for unparalleled security and features a robust dual locking mechanism that ensures maximum reliability. When paired with the top locking strip, it becomes virtually fail-proof, staying securely in place even where other fastening solutions have failed. This exceptional resilience makes the system the most reliable solution on the market.

ACE is engineered for extreme conditions. The robust construction materials and design contribute to a longer service life, even under challenging operating conditions. A dual-locking system ensures ACE stays secure even in toughest environments.

When it comes time for removal, ACE requires no screwdrivers or pry bars. Multotec’s engineered, battery-powered tool makes panel removal simple, fast, and safe — the smarter way to get the job done.

Customisable (diverse material options and aperture config, panel dimensions)

The ACE system is designed to be fully customisable to meet diverse operational needs. Manufactured from high-quality rubber, polyurethane, and wedge wire, ACE panels offer excellent wear resistance, ideal for handling abrasive materials.

This innovative system is adaptable, with customisable apertures and a range of material options that align with individual process flow requirements, effectively reducing common problems like pegging and blinding. Plus, ACE’s modular design ensures seamless integration into various screening systems and can be manufactured to any configuration currently in use in the market.

ACE’s customisability extends to its capacity for multiple media types, including wedge wire, punch plate, rubber, and polyurethane, enabling it to adapt to any process, material and wear profile. ACE is suitable for various mineral processing tasks such as sorting, dewatering, and scalping.

Performance enhancing

Not only is ACE safe and long-lasting, but it can improve your operational efficiency.

The use of advanced polymers extends the component life, thereby reducing the frequency and cost of replacements. The improved clipping system ensures the panels are firmly in place, resulting in fewer failures and decreased unplanned maintenance.

By preventing material misplacement and short-circuiting, ACE panels maintain consistent screening performance, resulting in more precise product sizing. The panels’ modular nature allows only worn panels to be replaced, further reducing downtime and maintenance expenses.

By reducing replacement and failure rates, ACE reduces operational interruptions, leading to enhanced productivity.

The system also diminishes the total cost of ownership and life cycle costs, thereby reducing per ton consumption costs for clients. This, in turn, optimises profits by minimising downtime and operational costs.

All these benefits are supported by Multotec’s significant investment in the cutting-edge Berrinba facility for polyurethane screening media, amplifying production capacity and propelling efficiency across operations.

Proudly built at the state-of-the-art Berrinba facility in Australia, ACE is helping plants across the region crush production targets and cut costs.

Still using old-school panels? It’s time to change it up. To discover how ACE is transforming screening, call +61 7 3442 0100 or visit multotec.com.au.