Aquila mine named innovation award finalist

A breakthrough underground excavation guard at Anglo American’s Aquila coal mine has been named a finalist at the 2025 Prospect Awards.

The new system — dubbed The Armadillo for its unique shield design and first-of-its-kind industry adaptability in Bowen Basin coal mines — has been recognised in the Innovative Mining Solution category for its use on the site near Middlemount, Queensland.

Developed in partnership with the Jet Group in Mackay, The Armadillo was designed when the mine turned a complex engineering challenge into an opportunity to innovate. The Aquila team needed to retrofit a conveyor dewatering transfer installation underground but faced several constraints, including low seam height and the need to keep the conveyor running for production continuity.

Aquila Mine general manager Braedon Smith says a novel solution to protect the conveyor while allowing shot firing excavation overhead needed to be developed.

The resulting mobile conveyor excavation guard had redefined how mining operations could safely excavate above live infrastructure without compromising production or safety.

“The Armadillo has delivered significant downtime reductions, zero injuries and a blueprint for safer underground excavation across the industry,” Mr Smith said.

The system was trialled and refined through rigorous risk assessments, 3D tunnel scans for precision and stakeholder workshops.

“The transferability of this first-of-its-kind system make scaling the innovation and adapting to site specific needs a value-add development for the industry,” Mr Smith said.

“The Armadillo is already being considered for future applications across the mine site and other Anglo American mining operations in the Bowen Basin. Its modular design and transferability make it a standout for sites facing similar excavation challenges.”

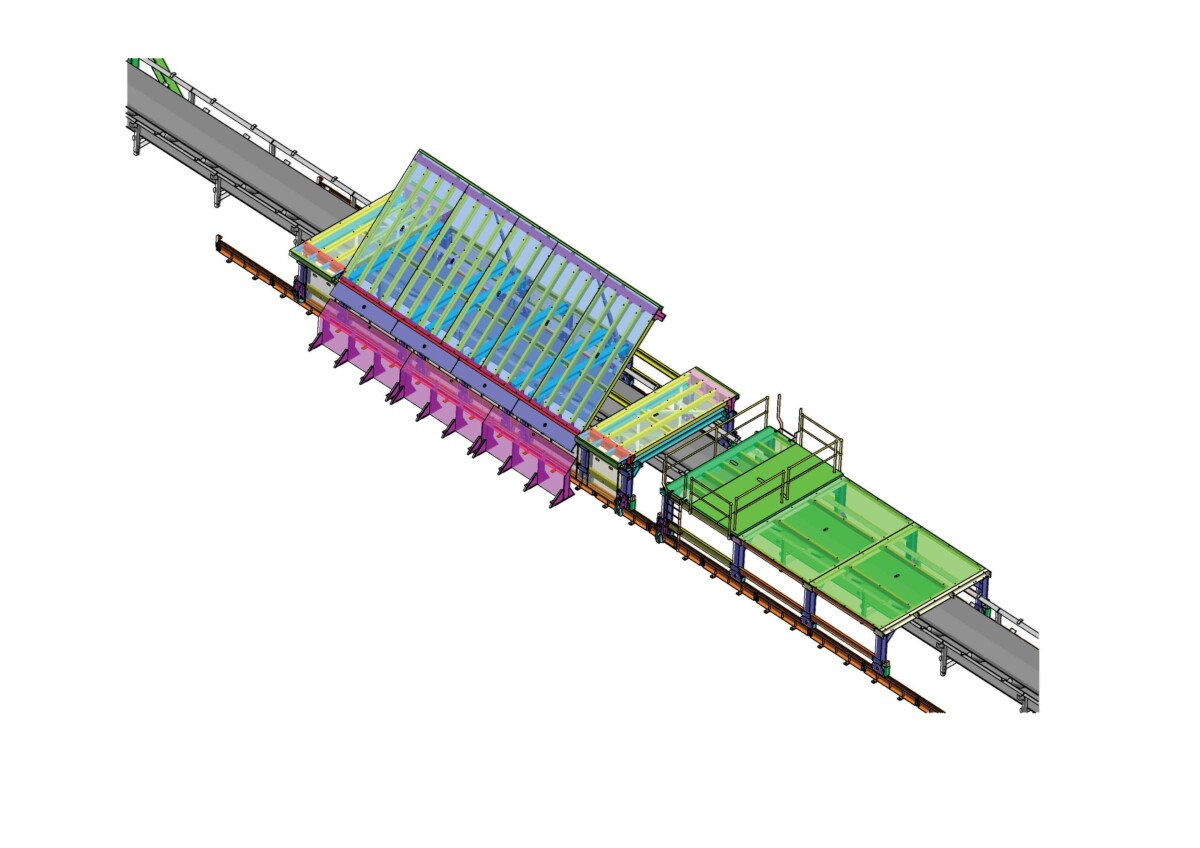

The Armadillo integrates rolling covers, a pivoting tipping platform, hydraulic controls and a custom rail system — all designed to shield the conveyor while enabling safe excavation and debris removal.

Anglo American Australia chief executive Dan van der Westhuizen says this project demonstrated the value of collaborative partnerships within the industry to achieve an innovative outcome.

“We are proud to be finalists but, more importantly, we’re proud of the collaboration and out-of-the-box thinking that made this solution possible,” he said.

“It’s a testament to what is achievable when safety, engineering and production teams come together.”

Key Armadillo features include:

- Rolling covers for flexible protection during blasting

- A tipping platform to safely transfer spoil to designated zones

- A bolting deck that doubles as a secondary safety layer

- Hydraulic cylinders for precise, low-risk tipping control

- Survey-guided installation for pinpoint accuracy

The 2025 awards will be held in Adelaide on September 24.