Weir unveils new ENDURON crushers

Weir, a global leader in mining technology, has launched a new range of ENDURON jaw and cone crushers, developed in close collaboration with customers to address their most pressing operational challenges.

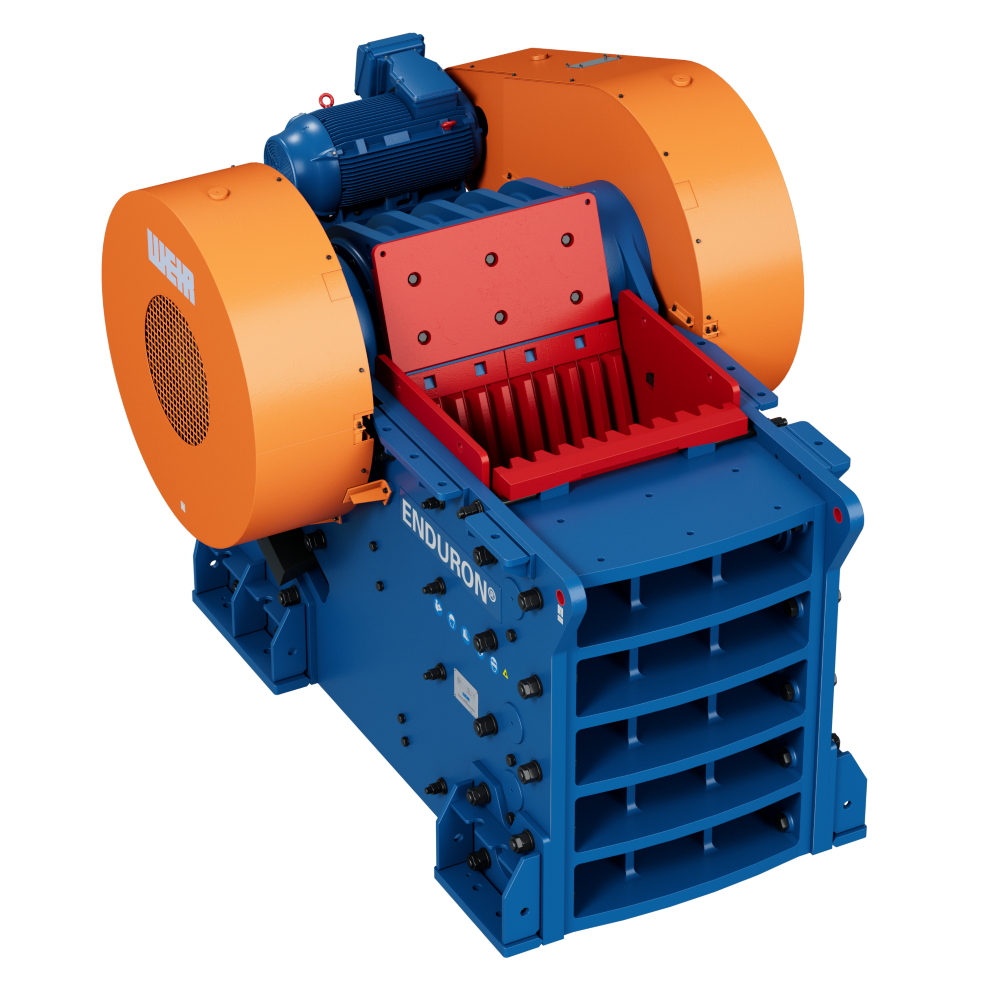

This customer-first approach has resulted in equipment that enhances safety, boosts productivity, simplifies maintenance, and supports sustainability goals. The updated ENDURON jaw crushers now feature a redesigned Hydraulic Power Unit (HPU), which allows for true push[1]button control of CSS adjustments. This innovation eliminates the need for manual intervention, significantly reducing safety risks for operators and maintenance teams. The new HPU also ensures consistent tensioning of the retraction springs at all times, improving reliability and ease of use across the full wear range of the jaw dies. The optimised motor power and oil tank capacity reduce the HPU’s carbon dioxide footprint and reduce environmental impact.

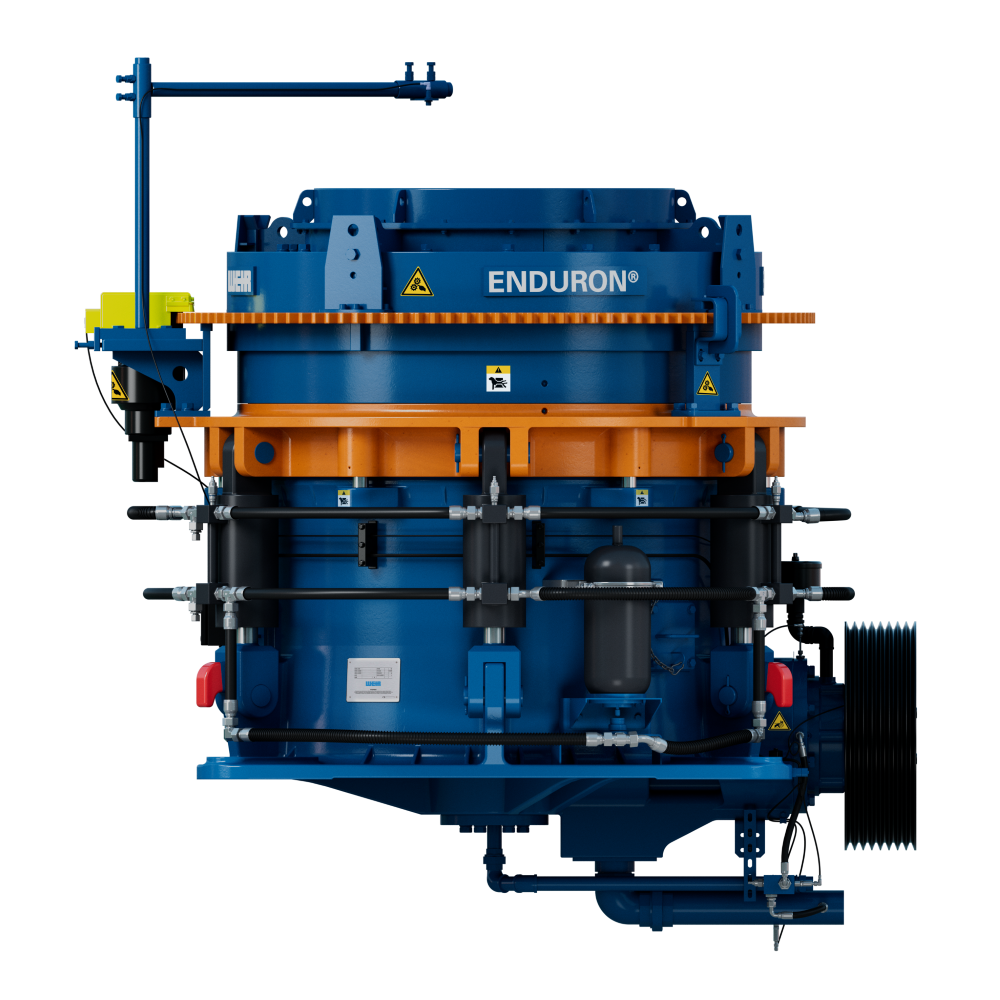

To further improve performance and reduce downtime, the entire range of ENDURON jaw crushers now includes ESCO wear parts. These components have been rigorously tested and proven to extend wear life, which means fewer maintenance interventions and increased equipment utilisation—translating to lower operating costs and more efficient production. The upgraded ENDURON cone crushers also benefit from ESCO wear liners and a newly designed Hydraulic and Lubrication Power Unit (H/LPU). This compact, plug-and-play system reduces the environmental footprint and simplifies installation, making it ideal for sites looking to streamline setup and minimise impact. Additionally, the automation platform across all cone crusher models has been enhanced to ensure consistent and reliable crushing operations. With IO-link digital sensors and Siemens PLC hardware, customers can expect seamless integration, easier troubleshooting, and intuitive control through a new Human-Machine Interface (HMI), which simplifies servicing and improves operational efficiency.

Weir’s new crusher range includes the ENDURON ET jaw crushers, as well as both the EP fixed-shaft and EC live-shaft cone crushers, offering tailored solutions to meet the specific needs of each site and application. This flexibility ensures that customers can select the ideal equipment for their unique operational requirements.

By complementing the existing ENDURON screens and HPGRs, the new crushers enable customers to build fully integrated flowsheets that reduce energy consumption and improve overall performance.

Weir crushers global product manager Magnus Skorvald emphasised the importance of customer feedback in shaping the new range.

“We’ve listened closely to our customers and designed this range to meet their evolving needs,” he said.

“From safety and sustainability to ease of installation and maintenance, every feature is built to deliver real value on site.

“Whether upgrading existing equipment or planning a new installation, the ENDURON range of comminution products is built to help customers operate smarter, safer, and more sustainably.”