Extending critical mineral deposit life with sensor-based sorting

TOMRA Mining’s sensor-based sorting technologies are transforming once-discarded material into a valuable resource, extending mine life and strengthening supply security for the energy transition.

Sensor-based sorting is emerging as a transformative technology, enabling more efficient recovery of minerals while reducing environmental impact, as mining operators face mounting pressure with declining ore grades, rising global demand for critical minerals and intensifying ESG expectations.

By separating barren material early in the process, miners can significantly reduce energy, water and chemicals required for downstream treatment, unlocking value from ore that was previously uneconomic. This shift enables operations to recover more from what they already mine, turning lower-grade and marginal deposits into viable resources.

As ore grades continue to decline and operational costs rise, it has become increasingly important for mining companies to extract maximum value from every tonne of material.

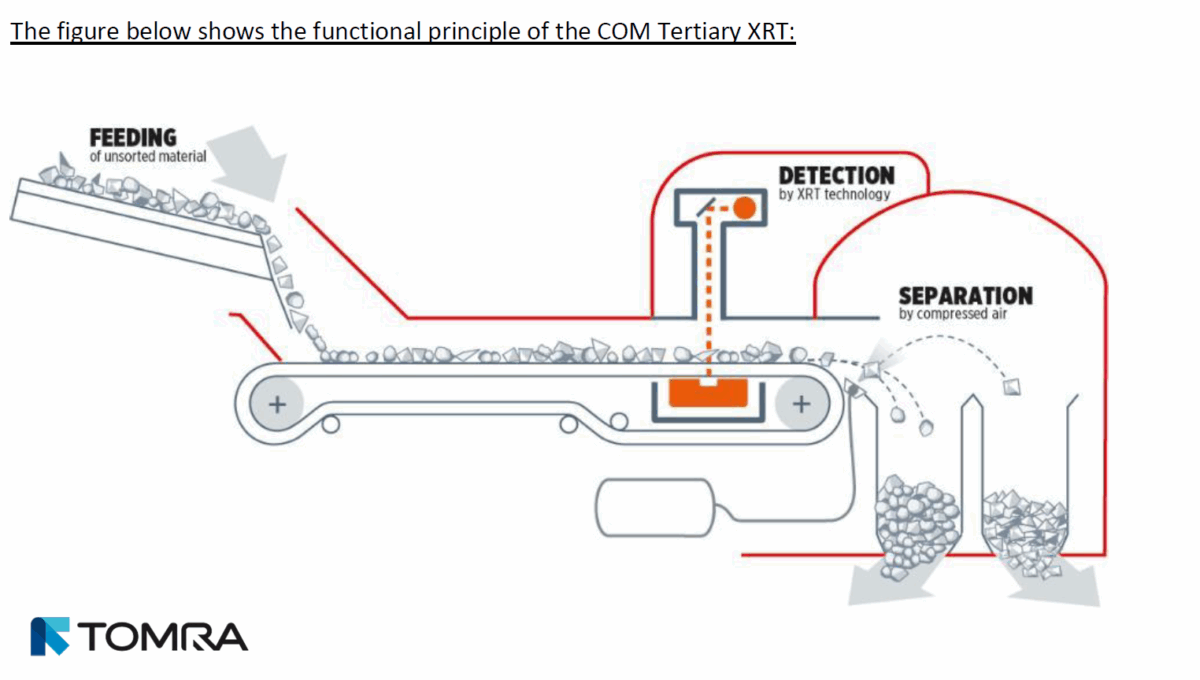

TOMRA Mining applies cutting-edge x-ray transmission (XRT), near-infrared (NIR) and laser sorting technologies to selectively separate valuable minerals from waste rock before processing. This early intervention reduces the need to crush, mill and chemically treat all mined material, lowering the use of energy and inputs, increasing recovery rates and substantially reducing tailings volumes.

TOMRA Mining global segment metals manager Rasoul Rezai says sensor-based sorting addresses one of mining’s greatest inefficiencies.

“We are able to recover more metal from the same amount of material,” he says.

“By rejecting waste early, operators feed higher-grade material into their mills, reduce operational expenditure, and improve overall efficiency. This is particularly crucial for critical minerals, where supply tensions are increasing worldwide.”

This approach has delivered tangible results in mines across the world. At Eloro Resources’ Iska Iska polymetallic project in southern Bolivia, TOMRA’s XRT ore sorting tests demonstrated the potential to reject significant quantities of sub-cut-off-grade waste, which dramatically reduces the capital and operating costs, permitting lower-grade ore blocks to be processed.

In Europe, TOMRA Mining is contributing its expertise to the Li4Life project, which aims to develop technologies that enable access to lithium from existing mining deposits and tailings, reducing pressure on primary supply. This collaboration highlights the growing recognition of sensor-based sorting as a vital technology for ensuring the long-term security of critical minerals supply chains.

Technology that redefines resource recovery

Recent AI-powered advancements have expanded the capabilities of TOMRA’s XRT sorters. OBTAIN can double sorting capacity without changing the machine’s size and mechanical design, while CONTAIN detects inclusion-type ores such as tin, tungsten, nickel, copper and sulfides, revealing even the smallest inclusions. Together, they form what Mr Rezai describes as “a new set of wings” for XRT technology.

Another breakthrough, the TS100 precision ejection system, reduces air consumption by up to 70%, lowering operational costs and increasing recovery even further. TOMRA’s portfolio of technologies allows operators to tailor solutions to the specific characteristics of each ore and deposit.

“Sensor-based sorting doesn’t just improve processing, it reshapes mining strategy,” Mr Rezai said.

“By increasing the grade of feed to the mill and rejecting waste early, operators can extract more value from the same deposit, increasing both the size and longevity of the mine.”

Driving the future of critical mineral supply

The role of sensor-based sorting in critical mineral production is gaining recognition across the mining industry. Pioneering projects such as the Pilbara lithium plant in WA have consolidated sensor-based sorting as a game changer in critical mineral processing, demonstrating both reliability and measurable economic and environmental benefits.

“Efficiency and recovery are paramount in an era of declining ore grades and rising demand,” Mr Rezai said.