MINExpo – What Happened in Vegas…

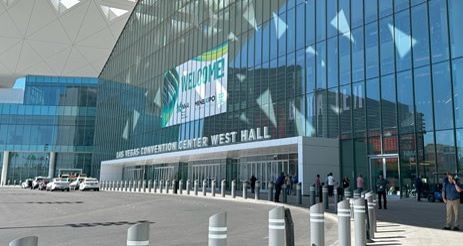

In the case of MINExpo International 2024, what happened in Vegas should definitely not stay in Vegas. This enormous expo brought together an eclectic mix of equipment, technology, innovation and sheer brute strength at an unprecedented scale.

To put that scale into perspective, the exhibition covered over 850,000 square feet. That may not mean a great deal to us in Australia but that equates to 7.8-hectares or over 19.5-acres. Spread across this vast floor area were over 2000 exhibitors representing every facet of the mining industry, from small businesses to huge multinationals.

To put that scale into perspective, the exhibition covered over 850,000 square feet. That may not mean a great deal to us in Australia but that equates to 7.8-hectares or over 19.5-acres. Spread across this vast floor area were over 2000 exhibitors representing every facet of the mining industry, from small businesses to huge multinationals.

The success of an exhibition is judged by its level of attendance and this did not disappoint either, with over 45,000 people passing through the doors over three days. Those attendees came from over 148 different countries, making the event a truly international affair.

One novel and very entertaining feature of the expo was the fleet of 35 Teslas that shuttled attendees through LED-lit underground tunnels from one convention hall to the other.

This free service was a welcome relief from having to make the walk outside in 37°C heat.

Monsters on Display

The Central Hall was home to the behemoths of the show, with Caterpillar, Komatsu, Liebherr and Hitachi showcasing some of their giants.

The Australian Mining Review was invited to Liebherr’s press conference where their team from Germany explained the many new innovations they have in the pipeline as well as their significant partnership with Fortescue to deliver 475 machines to the WA mining company and help them on their stratospheric trajectory towards zero emissions mining.

Fortescue Zero developed the battery technology and is working in conjunction with Liebherr to supply the powerplants for over 360 T264 battery-electric autonomous haul trucks.

Also in development and also utilising the battery power system, is a zero emission dozer – the PR 776. Once fully commissioned, Liebherr will supply 60 of these to Fortescue in Australia. In pride of place next to the exciting new T264 was the looming presence of Liebherr’s R 9400 E electric excavator. This machine took two weeks to assemble at the convention hall.

It sat on special steel plates to dissipate the massive weight over the floor, so as not to damage the concrete. The carpet was then laid over the steel and the construction of this impressive electric excavator began. Fortescue already have three of these machines operating in Australia.

Their sheer size is impressive, as is the technology that permits it to run through a massive electric cable and reel on the back of the machine. 55 more R 9400 Es will be supplied as part of the single largest order received by Liebherr in its 75-year history. The total value of the 475 machines and their respective battery power supplies is around US$2.8-billion. Dr Andrew Forrest and Dr Willi Liebherr were at MINExpo to celebrate this landmark partnership that is set to change the face of global mining.

An equally impressive monster was on display at the Komatsu stand. Their WE2350 is the largest wheel loader in the world, with 2300hp on tap and the ability to move up to 72.5-tonnes in a single 40m3 bucket.

The WE2350 cut an impressive silhouette, dwarfing the crowd that swarmed around and over it for a closer look. Designed to centre load ultra-class 400-tonne dump trucks, this 266-tonne beast is highly flexible in its application and more mobile than a tracked excavator.

The Caterpillar stand was the largest at the event and housed a host of machinery, multiple cinemas, merchandise huts, simulators, landscaped pathways and more.

In pride of place was Cat’s 798 haul truck, featuring their new Dynamic Energy Transfer (DET) system. This fully Caterpillar- developed system can transfer energy to both diesel-electric and battery-electric trucks while they are in operation.

It can also charge a machine’s batteries while operating with increased speed on an incline.

Cat DET incorporates a power module that converts energy from a mine site’s power source, an electrified rail system to transmit the energy and a machine system to transfer the energy to the truck’s powertrain.

Hitachi had their own monster EX5600 face shovel on display too, this machine boasts twin Cummins 1500hp engines, tips the scales at over half-a-million kilograms and has a 29m3 shovel bucket capable of filling a 296-tonne dump truck in only six passes. Speaking of dump trucks, Hitachi’s impressive EH4000 AC5 was parked nearby, making its debut at MINExpo.

This new model (upgraded from their AC3) has achieved the industry’s highest payload of 242-tonnes in the 400-tonne class,

according to Hitachi. There is also an option to run the AC5 with batteries and a trolley dynamic charging system