Aussie’s stainless revolution

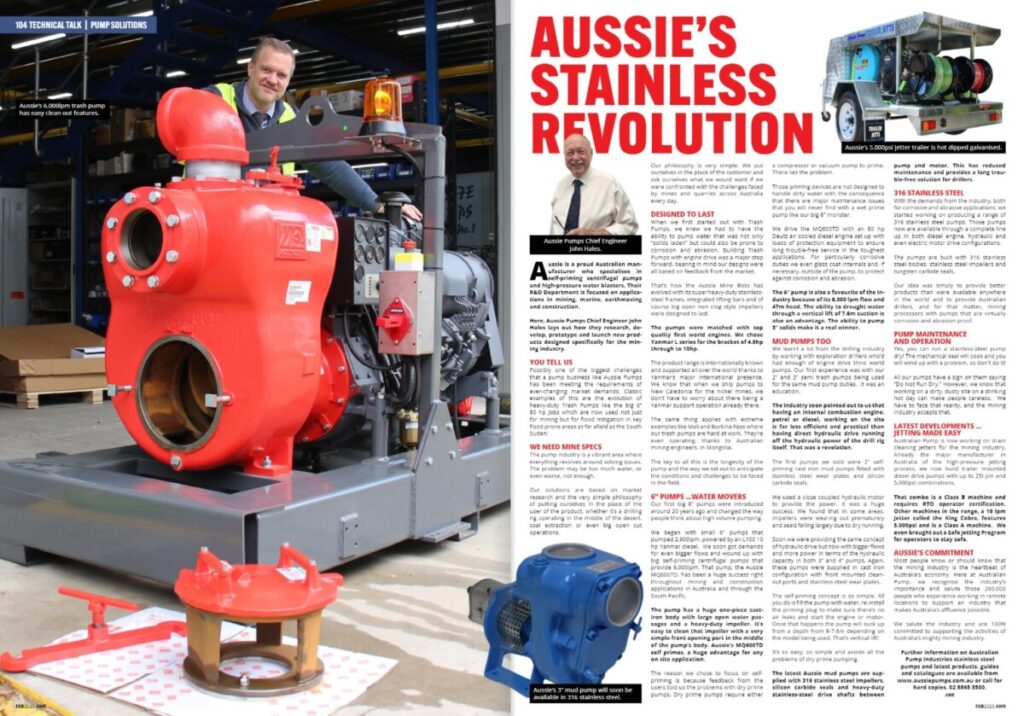

Aussie is a proud Australian manufacturer who specialises in self-priming centrifugal pumps and high-pressure water blasters. Their R&D Department is focused on applications in mining, marine, earthmoving and construction.

Here, Aussie Pumps Chief Engineer John Hales lays out how they research, develop, prototype and launch new products designed specifically for the mining industry.

You tell us

Possibly one of the biggest challenges that a pump business like Aussie Pumps has been meeting the requirements of ever-changing market demands. Classic examples of this are the evolution of heavy-duty Trash Pumps like the big 6” 80 hp jobs which are now used not just for mining but for flood mitigation in key flood prone areas as far afield as the South Sudan!

We need mine specs

The pump industry is a vibrant area where everything revolves around solving issues. The problem may be too much water, or even worse, not enough.

Our solutions are based on market research and the very simple philosophy of putting ourselves in the place of the user of the product, whether it’s a drilling rig operating in the middle of the desert, coal extraction or even big open cut operations.

Our philosophy is very simple. We put ourselves in the place of the customer and ask ourselves what we would want if we were confronted with the challenges faced by mines and quarries across Australia every day.

Designed to last

When we first started out with Trash Pumps, we knew we had to have the ability to pump water that was not only “solids laden” but could also be prone to corrosion and abrasion. Building Trash Pumps with engine drive was a major step forward, bearing in mind our designs were all based on feedback from the market.

That’s how the Aussie Mine Boss has evolved with its super heavy-duty stainless- steel frames, integrated lifting bars and of course big open non clog style impellers were designed to last.

The pumps were matched with top quality first world engines. We chose Yanmar L series for the bracket of 4.8hp through to 10hp.

The product range is internationally known and supported all over the world thanks to Yanmar’s major international presence. We know that when we ship pumps to New Caledonia for the nickel mines, we don’t have to worry about there being a Yanmar support operation already there.

The same thing applies with extreme examples like Mali and Burkina Faso where our trash pumps are hard at work. They’re even operating, thanks to Australian mining engineers, in Mongolia.

The key to all this is the longevity of the pump and the way we set out to anticipate the conditions and challenges to be faced in the field.

6” pumps …water movers

Our first big 6” pumps were introduced around 20 years ago and changed the way people think about high volume pumping.

We began with small 6” pumps that pumped 2,900lpm, powered by an L100 10 hp Yanmar diesel. We soon got demands for even bigger flows and wound up with big self-priming centrifugal pumps that provide 6,000lpm. That pump, the Aussie MQ600TD, has been a huge success right throughout mining and construction applications in Australia and through the South Pacific.

The pump has a huge one-piece cast- iron body with large open water pas- sages and a heavy-duty impeller. It’s easy to clean that impeller with a very simple front opening port in the middle of the pump’s body. Aussie’s MQ600TD self primes, a huge advantage for any on site application.

The reason we chose to focus on self- priming is because feedback from the users told us the problems with dry prime pumps. Dry prime pumps require either a compressor or vacuum pump to prime.

There lies the problem.

Those priming devices are not designed to handle dirty water with the consequence that there are major maintenance issues that you will never find with a wet prime pump like our big 6” monster.

We drive the MQ600TD with an 80 hp Deutz air cooled diesel engine set up with loads of protection equipment to ensure long trouble-free service in the toughest applications. For particularly corrosive duties we even glass coat internals and, if necessary, outside of the pump, to protect against corrosion and abrasion.

The 6” pump is also a favourite of the in- dustry because of its 6,000 lpm flow and 47m head. The ability to draught water through a vertical lift of 7.6m suction is also an advantage. The ability to pump 3” solids make it a real winner.

Mud pumps too

We learnt a lot from the drilling industry by working with exploration drillers who’d had enough of engine drive third world pumps. Our first experience was with our 2” and 3” semi trash pumps being used for the same mud pump duties. It was an education.

The industry soon pointed out to us that having an internal combustion engine, petrol or diesel, working on the site is far less efficient and practical than having direct hydraulic drive running off the hydraulic power of the drill rig itself. That was a revelation.

The first pumps we sold were 2” self- priming cast iron mud pumps fitted with stainless steel wear plates and silicon carbide seals.

We used a close coupled hydraulic motor to provide the power. It was a huge success. We found that in some areas, impellers were wearing out prematurely and seals failing largely due to dry running.

Soon we were providing the same concept of hydraulic drive but now with bigger flows and more power in terms of the hydraulic capacity in both 3” and 4” pumps. Again, these pumps were supplied in cast iron configuration with front mounted clean- out ports and stainless-steel wear plates.

The self-priming concept is so simple. All you do is fill the pump with water, re-install the priming plug to make sure there’s no air leaks and start the engine or motor. Once that happens the pump will suck up from a depth from 6-7.6m depending on the model being used. That’s vertical lift!

It’s so easy, so simple and avoids all the

problems of dry prime pumping.

The latest Aussie mud pumps are sup- plied with 316 stainless steel impellers, silicon carbide seals and heavy-duty stainless-steel drive shafts between pump and motor. This has reduced maintenance and provides a long trou- ble-free solution for drillers.

316 stainless steel

With the demands from the industry, both for corrosive and abrasive applications, we started working on producing a range of 316 stainless steel pumps. Those pumps now are available through a complete line up in both diesel engine, hydraulic and even electric motor drive configurations.

The pumps are built with 316 stainless steel bodies, stainless steel impellers and tungsten carbide seals.

Our idea was simply to provide better products than were available anywhere in the world and to provide Australian drillers, and for that matter, mining processors with pumps that are virtually corrosion and abrasion proof.

Pump maintenance and operation

Yes, you can run a stainless-steel pump dry! The mechanical seal will cook and you will wind up with a problem, so don’t do it!

All our pumps have a sign on them saying “Do Not Run Dry.” However, we know that working on a dirty, dusty site on a stinking hot day can make people careless. We have to face that reality, and the mining industry accepts that.

Latest developments … jetting made easy

Australian Pump is now working on drain cleaning Jetters for the mining industry. Already the major manufacturer in Australia of the high-pressure jetting process, we now build trailer mounted diesel drive pumps with up to 25l pm and 5,000psi combinations.

That combo is a Class B machine and requires RTO operator certification. Other machines in the range, a 16 lpm Jetter called the King Cobra, features 5,000psi and is a Class A machine. We even brought out a Safe Jetting Program for operators to stay safe.

Aussie’s commitment

Most people know or should know that the mining industry is the heartbeat of Australia’s economy. Here at Australian Pump, we recognise the industry’s importance and salute those 260,000 people who experience working in remote locations to support an industry that makes Australia’s affluence possible.

We salute the industry and are 100% committed to supporting the activities of Australia’s mighty mining industry.

Further information on Australian Pump Industries stainless steel pumps and latest products, guides and catalogues are available from www.aussiepumps.com.au or call for hard copies. 02 8865 3500.