Natural dust suppression that saves money and lasts longer

The impact of airborne dust on infrastructure and the health of workers can’t be overlooked. In mines, construction sites, and agricultural land, dust particles generated by earthmoving and material handling equipment, stagnant stockpiles, vehicles, and windy conditions, can result in machine breakdown costly maintenance, and project delays.

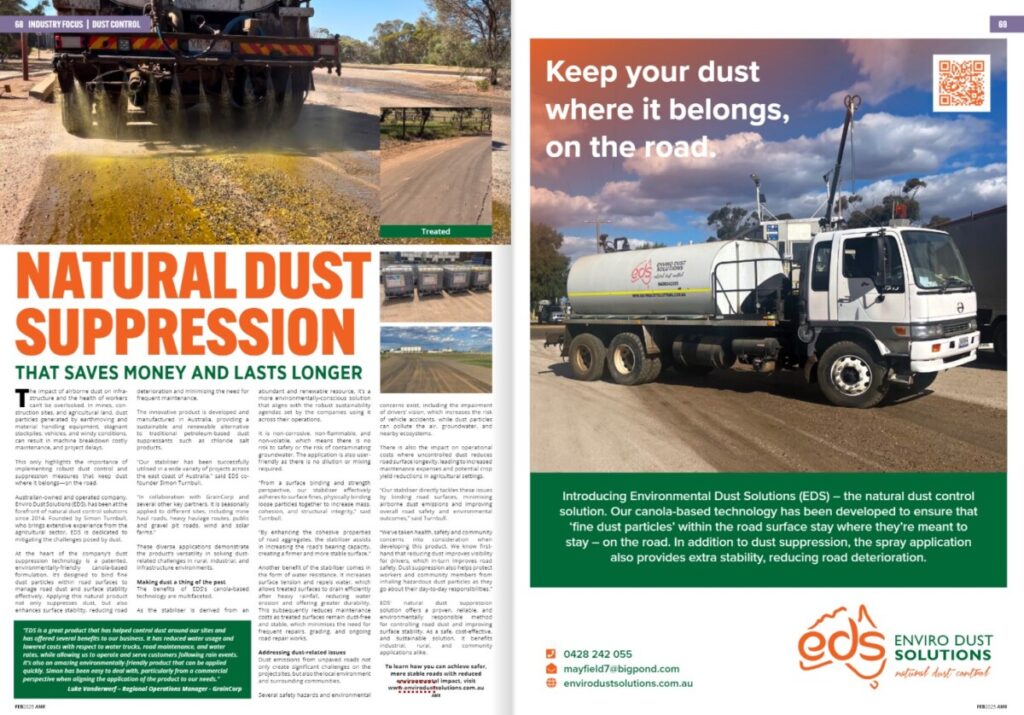

This only highlights the importance of implementing robust dust control and suppression measures that keep dust where it belongs—on the road.

Australian-owned and operated company, Enviro Dust Solutions (EDS), has been at the forefront of natural dust control solutions since 2014. Founded by Simon Turnbull, who brings extensive experience from the agricultural sector, EDS is dedicated to mitigating the challenges posed by dust.

At the heart of the company’s core service offering is a patented canola-based, environmentally friendly dust suppression technology. It’s designed to bind fine dust particles within road surfaces to manage road dust and surface stability effectively. Applying this natural product not only suppresses dust, but also enhances surface stability, reducing road deterioration and minimising the need for frequent maintenance.

The innovative product is developed and manufactured in Australia, providing a sustainable and renewable alternative to traditional petroleum-based dust suppressants such as chloride salt products.

“Our stabiliser has been successfully utilised in a wide variety of projects across the east coast of Australia,” said EDS co-founder Simon Turnbull.

“In collaboration with GrainCorp and several other key partners, it is seasonally applied to different sites, including mine haul roads, heavy haulage routes, public and gravel pit roads, wind and solar farms.”

These diverse applications demonstrate the product’s versatility in solving dust-related challenges in rural, industrial, and infrastructure environments.

Making dust a thing of the past

The benefits of EDS’s canola-based technology are multifaceted.

As the stabiliser is derived from an abundant and renewable resource, it’s a more environmentally-conscious solution that aligns with the robust sustainability agendas set by the companies using it across their operations.

It is non-corrosive, non-flammable, and non-volatile, which means there is no risk to safety or the risk of contaminating groundwater. The application is also user-friendly as there is no dilution or mixing required.

“From a surface binding and strength perspective, our stabiliser effectively adheres to surface fines, physically binding loose particles together to increase mass, cohesion, and structural integrity,” said Turnbull.

“By enhancing the cohesive properties of road aggregates, the stabiliser assists in increasing the road’s bearing capacity, creating a firmer and more stable surface.”

Another benefit of the stabiliser comes in the form of water resistance. It increases surface tension and repels water, which allows treated surfaces to drain efficiently after heavy rainfall, reducing water erosion and offering greater durability. This subsequently reduces maintenance costs as treated surfaces remain dust-free and stable, which minimises the need for frequent repairs, grading, and ongoing road repair works.

Addressing dust-related issues

Dust emissions from unpaved roads not only create significant challenges on the project sites, but also the local environment and surrounding communities.

Several safety hazards and environmental concerns exist, including the impairment of drivers’ vision, which increases the risk of vehicle accidents, while dust particles can pollute the air, groundwater, and nearby ecosystems.

There is also the impact on operational costs where uncontrolled dust reduces road surface longevity, leading to increased maintenance expenses and potential crop yield reductions in agricultural settings.

“Our stabiliser directly tackles these issues by binding road surfaces, minimising airborne dust emissions and improving overall road safety and environmental outcomes,” said Turnbull.

“We’ve taken health, safety and community concerns into consideration when developing this product. We know first-hand that reducing dust improves visibility for drivers, which in-turn improves road safety. Dust suppression also helps protect workers and community members from inhaling hazardous dust particles as they go about their day-to-day responsibilities.”

EDS’ natural dust suppression solution offers a proven, reliable, and environmentally responsible method for controlling road dust and improving surface stability. As a safe, cost-effective, and sustainable solution, it benefits industrial, rural, and community applications alike.

To learn how you can achieve safer, more stable roads with reduced environmental impact, visit www.envirodustsolutions.com.au/