The efficiencies of layflat hose systems for mine dewatering

Effective dewatering is critical for the smooth operation of mining activities, as excessive water accumulation in mines can hinder productivity, increase safety risks, and damage equipment. Traditional dewatering methods often involve rigid piping systems that, while functional, can present significant challenges regarding efficiency, portability, and cost. Layflat hose systems from Crusader Hose have emerged as a superior alternative, offering a range of benefits that make them ideal for mine dewatering operations.

1. Rapid Deployment and Recovery

One of the most significant advantages of layflat hose systems over rigid pipe is how easily and quickly layflat pipelines can be positioned. Designed to redefine efficiency and reliability, the Waterlord® Dewatering System guarantees quick deployment and retrieval, minimising downtime during setup or relocation. Their ease of handling enables teams to respond swiftly to changing water levels or shifts in dewatering requirements, ensuring uninterrupted operations.

One of the most significant advantages of layflat hose systems over rigid pipe is how easily and quickly layflat pipelines can be positioned. Designed to redefine efficiency and reliability, the Waterlord® Dewatering System guarantees quick deployment and retrieval, minimising downtime during setup or relocation. Their ease of handling enables teams to respond swiftly to changing water levels or shifts in dewatering requirements, ensuring uninterrupted operations.

2. Portability and Flexibility

Layflat hose is relatively lightweight and flexible in design. Unlike rigid pipes, which are bulky and cumbersome to transport, with the precision-engineered Hamersley reel drive unit, layflat hose can be easily rolled up, transported, and deployed in remote or rugged mining environments. Their flexibility allows them to navigate around obstacles, making them highly adaptable to the complex layouts of open-pit mines.

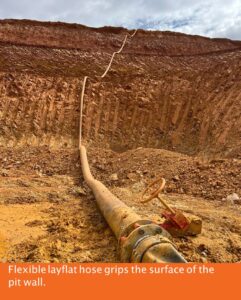

3. Defining feature vs poly

The surface friction of layflat hose against the pit wall is a key feature that highlights its efficiency. Layflat hose adapts to the contours of the pit wall and grips the surface at contact points, preventing it from sliding unless pulled. This frictional stability makes it safer and less risky to install layflat pipelines on high pit walls compared to using poly pipe. The layflat pipeline is deployed from the top of the pit by gently dragging it into position from the bottom of the pit via a winch or vehicle. This surface friction eliminates the need to anchor the hose at each bench.

4. Durability and Performance

Crusader Hose layflat hose is constructed from durable materials, featuring high-tensile polyester textile reinforcement and extruded thermoplastic polyurethane. This design allows the hoses to withstand harsh mining conditions, including abrasion, UV exposure, and chemical resistance. They can handle high-pressure flows and facilitate long-distance pumping without compromising performance. Manufactured in diameters up to 12”, they are ideal for high-volume dewatering tasks.

5. Cost Efficiency

Compared to rigid pipes, layflat hose systems are more cost-effective in several ways. Their lightweight design reduces transportation costs, while their flexibility eliminates the need for extensive welding and handling. With their state-of-the-art Boa clamps, couplings can be fitted on-site with minimum tools. Additionally, layflat hose can be retrieved and redeployed to other sites reducing replacement expenses over time.

6. Environmental Impact

In addition to being reusable and reducing plastic waste, layflat hose contributes to environmentally responsible mining practices. Rehabilitation costs to remove bulky poly pipes need to be factored in when comparing alternative layflat systems. Layflat hose can be easily wound up and redeployed.

7. Versatility

Layflat hose is compatible with a wide range of pumps and dewatering systems, making them a versatile choice for mining operations of all scales. They can handle varying flow rates and pressures, allowing operators to customise their dewatering solutions to specific site requirements.

Conclusion

Adopting layflat hose in mine dewatering operations can represent a significant step forward in efficiency, reliability, and cost-effectiveness. Their portability, durability, and adaptability make them a practical solution for managing water in high wall mining environments. As the mining industry continues to evolve, layflat hose is poised to play an increasingly important role in ensuring safe and profitable operations while minimising environmental impact.

By choosing layflat hoses, mining operators have the option to streamline their dewatering processes, reduce operational costs, and maintain a safer, more efficient work environment.

To find out more get in touch with the mine industry experts at Crusader Hose.

P: +61 3 9720 1100

E: sales@crusaderhose.com.au

W: www.crusaderhose.com.au