Ensuring cleanliness in bulk lube and oils

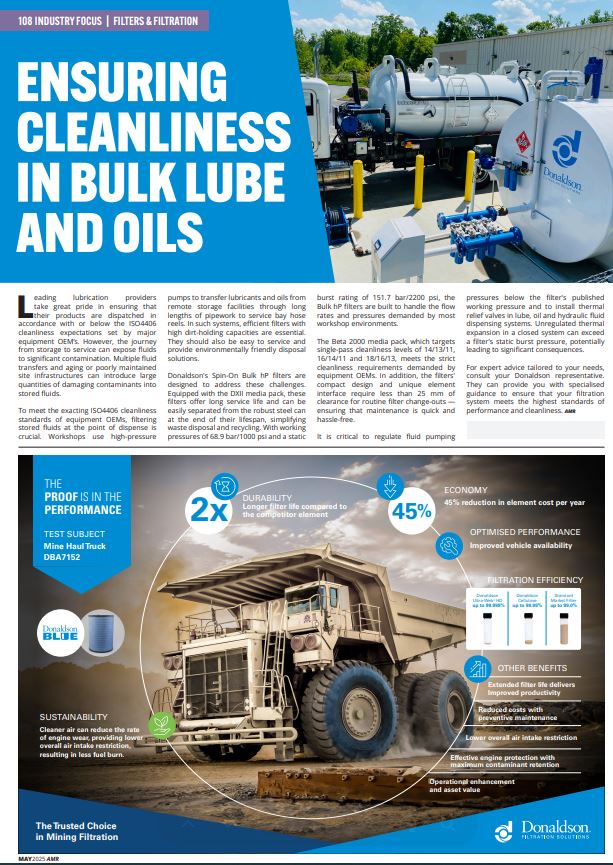

Leading lubrication providers take great pride in ensuring that their products are dispatched in accordance with or below the ISO4406 cleanliness expectations set by major equipment OEM’s. However, the journey from storage to service can expose fluids to significant contamination. Multiple fluid transfers and aging or poorly maintained site infrastructures can introduce large quantities of damaging contaminants into stored fluids.

To meet the exacting ISO4406 cleanliness standards of equipment OEMs, filtering stored fluids at the point of dispense is crucial. Workshops use high-pressure pumps to transfer lubricants and oils from remote storage facilities through long lengths of pipework to service bay hose reels. In such systems, efficient filters with high dirt-holding capacities are essential. They should also be easy to service and provide environmentally friendly disposal solutions.

Donaldson’s Spin-On Bulk hP filters are designed to address these challenges. Equipped with the DXII media pack, these filters offer long service life and can be easily separated from the robust steel can at the end of their lifespan, simplifying waste disposal and recycling. With working pressures of 68.9 bar/1000 psi and a static burst rating of 151.7 bar/2200 psi, the Bulk hP filters are built to handle the flow rates and pressures demanded by most workshop environments.

The Beta 2000 media pack, which targets single-pass cleanliness levels of 14/13/11, 16/14/11 and 18/16/13, meets the strict cleanliness requirements demanded by equipment OEMs. In addition, the filters’ compact design and unique element interface require less than 25 mm of clearance for routine filter change-outs — ensuring that maintenance is quick and hassle-free.

It is critical to regulate fluid pumping pressures below the filter’s published working pressure and to install thermal relief valves in lube, oil and hydraulic fluid dispensing systems. Unregulated thermal expansion in a closed system can exceed a filter’s static burst pressure, potentially leading to significant consequences.

For expert advice tailored to your needs, consult your Donaldson representative. They can provide you with specialised guidance to ensure that your filtration system meets the highest standards of performance and cleanliness