Varnish removal made easy

Forget about expensive and complex filtration rigs — the latest technology from Triple R Filtration is making varnish removal in lube oil simple, inexpensive and efficient.

The varnish problem

Oil degradation lies at the heart of varnish build-up for both lubrication and hydraulic systems. This degradation primarily arises from oxidation, hydrolysis and thermal degradation. In many instances, it’s a combination of these three factors. Oxidation, hydrolysis and thermal degradation all lead to the formation of undesirable byproducts such as sludge and varnish. Understanding these processes is essential for effective maintenance and optimisation of lubrication and hydraulic systems.

Oxidation

Oxidation signifies the oil’s breakdown through its interaction with oxygen. This process involves a series of reactions that leads to the formation of acidic and polymerized compounds known as varnish. Varnish resulting from oxidation is an insoluble product that can precipitate as a thin film. This film can give an increase of varnish deposits on both hot and cold metal surfaces.

Hydrolysis

Hydrolysis involves the oil’s breakdown through its contact with water. Like oxidation, hydrolysis can generate acidic compounds and varnish.

Thermal degradation

Thermal degradation occurs when oil breaks down due to elevated temperatures. This commonly takes place in the system’s hot spots. Thermal degradation can also result in the formation of polymers and insoluble compounds, leading to varnish creation.

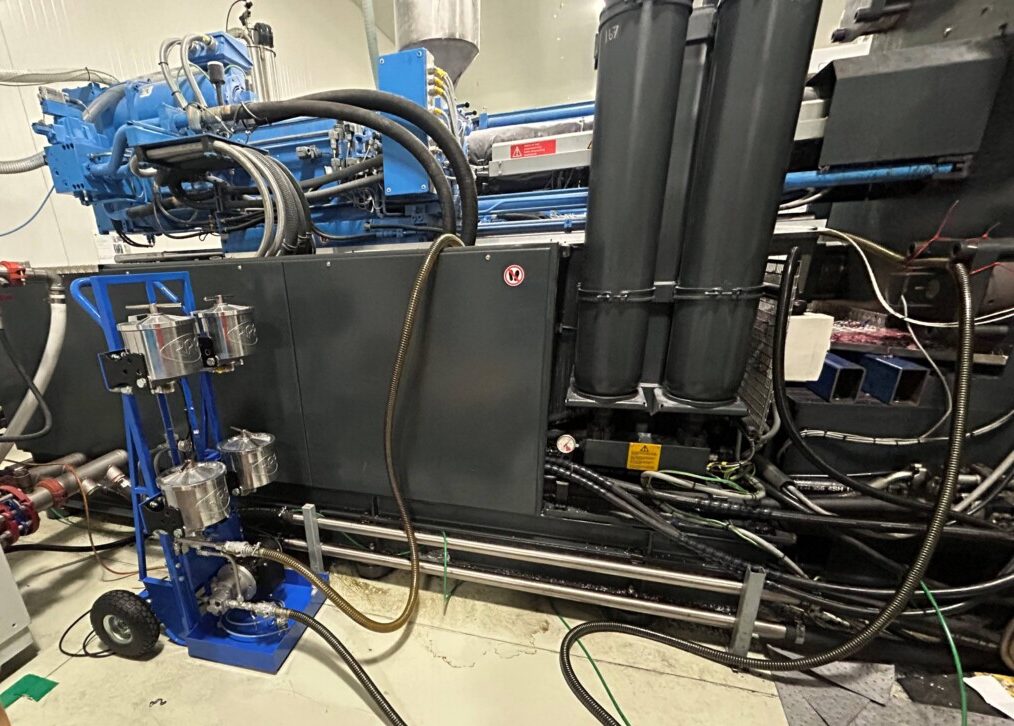

The Triple R Filtration Solution — V100 Varnish Removal Element

Over the course of four years of R&D and industrial trials, the V100 has been developed and proven to accelerate the elimination of varnish and oxidation byproducts.

Over four years of testing, the V100 element has achieved dropping MPC results from over 20 to below four in a single pass. These tests were conducted on the lubrication systems of well-known branded turbines in the power generation industry.

The V100 achieves varnish and oxidation byproducts absorption, hard contaminants filtration and water absorption all in a single element design. The technology simplifies the filtration process without needing to have a refrigerator to chill down the oil. The sludge and soft contaminants in oil are absorbed via the patented powder pack on top of a depth filter element.

The V100 Element fits into Triple R’s humble AL100 Filter Housings which have been integrated into many online and offline filtration systems for ease of use in maintenance.

Triple R Filtration Australia has a group of dedicated engineers providing custom solutions for your fluid engineering needs.