Eagle Forklifts

Powering Australia’s mining logistics with smarter, safer machinery

As the Australian mining sector continues its evolution toward smarter, cleaner, and more efficient operations, one constant remains: the need for reliable, heavy-duty machinery that thrives in harsh environments. Whether in the iron-rich dust of the Pilbara or the high-altitude coal fields of the Bowen Basin, equipment downtime is not an option.

Driving Performance in Harsh Terrain: The Eagle Forklifts Advantage

That’s where Eagle Forklifts delivers a competitive edge. With nearly 30 years of industry expertise, this Queensland-based, 100% Australian-owned company has built a reputation for supplying durable, versatile material handling equipment backed by fast support and deep operational and technical understanding.

Serving everyone from sub-contractors to major mining companies, Eagle Forklifts is focused on helping logistics teams stay productive, compliant, and prepared for the future of Australian mining.

The Fleet: Equipment Built for Mine Sites

From pit-edge operations to parts warehouses, Eagle Forklifts offers a scalable fleet capable of supporting the full spectrum of mining logistics needs—on any terrain, in any climate.

Options include:

- Forklifts – Electric, Diesel, LPG (1.5 tonne to heavy-duty 48 tonne lift capacities).

- Telehandlers – For versatile lifting and site maintenance.

- Scissor Lifts & Boom Lifts – For access at height, or maintenance of tall mining machinery, designed for both indoors and outdoors use.

- Tracked EWPs – For sloped or soft ground conditions.

- Pallet Jacks & Warehousing Units – Designed for increasing warehousing efficiencies.

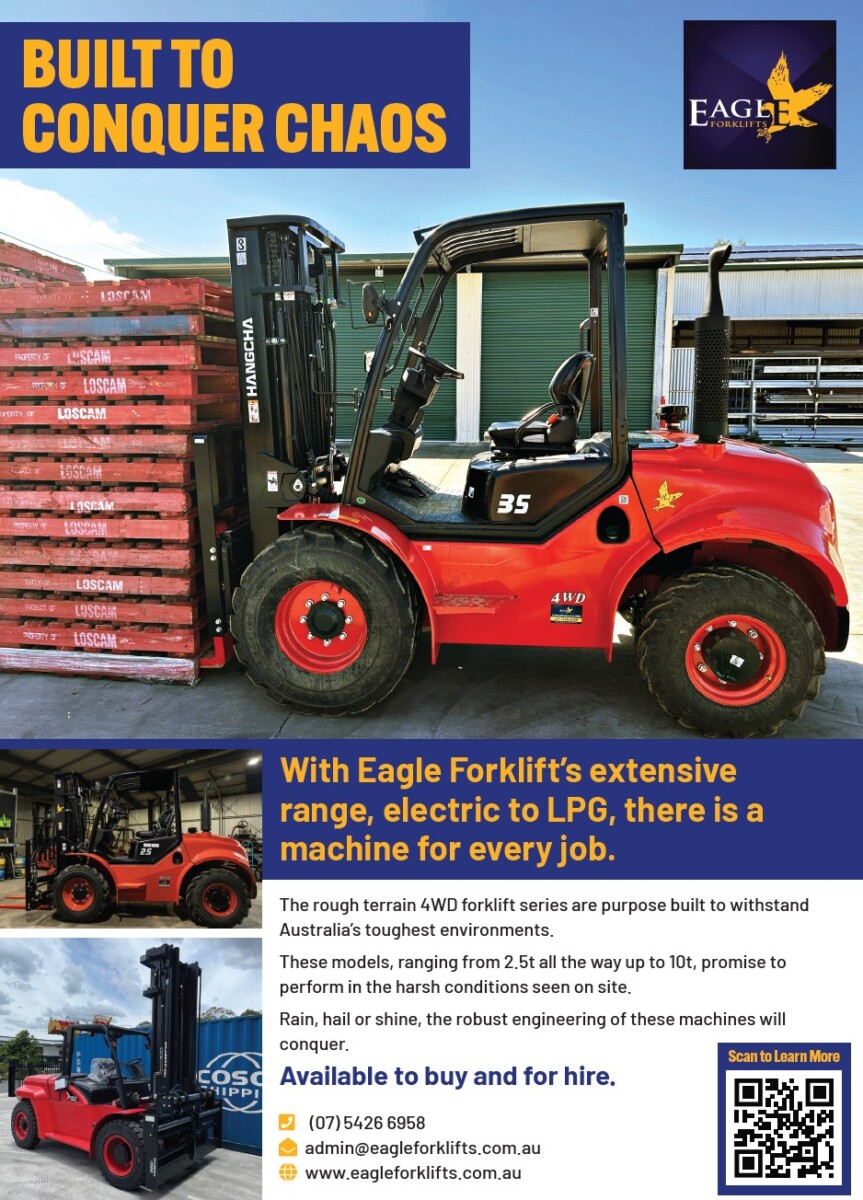

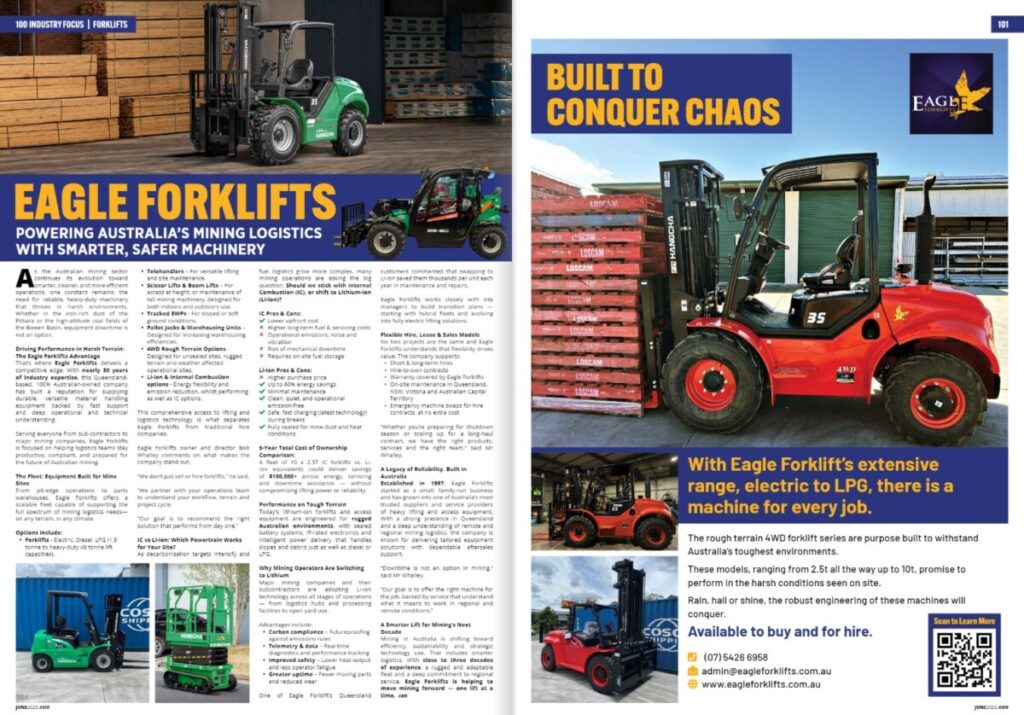

- 4WD Rough Terrain Options – Designed for unsealed sites, rugged terrain and weather affected operational sites.

- Li-ion & Internal Combustion options – Energy flexibility and emission reduction, whilst performing as well as IC options.

This comprehensive access to lifting and logistics technology is what separates Eagle Forklifts from traditional hire companies.

Eagle Forklifts owner and director Bob Whalley comments on what makes the company stand out.

“We don’t just sell or hire forklifts,” he said.

“We partner with your operations team to understand your workflow, terrain and project cycle.

“Our goal is to recommend the right solution that performs from day one.”

IC vs Li-ion: Which Powertrain Works for Your Site?

As decarbonisation targets intensify and fuel logistics grow more complex, many mining operations are asking the big question: Should we stick with Internal Combustion (IC), or shift to Lithium-ion (Li-ion)?

IC Pros & Cons:

- Lower upfront cost

- Higher long-term fuel & servicing costs

- Operational emissions, noise and vibration

- Risk of mechanical downtime

- Requires on-site fuel storage

Li-ion Pros & Cons:

- Higher purchase price

- Up to 60% energy savings

- Minimal maintenance

- Clean, quiet, and operational emission-free

- Safe, fast charging (latest technology) during breaks

- Fully sealed for mine-dust and heat conditions

5-Year Total Cost of Ownership Comparison:

A fleet of 10 x 2.5T IC forklifts vs. Li-ion equivalents could deliver savings of $100,000+ across energy, servicing and downtime avoidance — without compromising lifting power or reliability.

Performance on Tough Terrain

Today’s lithium-ion forklifts and access equipment are engineered for rugged Australian environments, with sealed battery systems, IP-rated electronics and intelligent power delivery that handles slopes and debris just as well as diesel or LPG.

Why Mining Operators Are Switching to Lithium

Major mining companies and their subcontractors are adopting Li-ion technology across all stages of operations — from logistics hubs and processing facilities to open yard use.

Advantages include:

- Carbon compliance – Futureproofing against emissions rules

- Telemetry & data – Real-time diagnostics and performance tracking

- Improved safety – Lower heat output and less operator fatigue

- Greater uptime – Fewer moving parts and reduced wear

One of Eagle Forklift’s Queensland customers commented that swapping to Li-ion saved them thousands per unit each year in maintenance and repairs.

Eagle Forklifts works closely with site managers to build transition plans — starting with hybrid fleets and evolving into fully electric lifting solutions.

Flexible Hire, Lease & Sales Models

No two projects are the same and Eagle Forklifts understands that flexibility drives value. The company supports:

- Short & long-term hires

- Hire-to-own contracts

- Warranty covered by Eagle Forklifts

- On-site maintenance in Queensland, NSW, Victoria and Australian Capital Territory

- Emergency machine swaps for hire contracts, at no extra cost

“Whether you’re preparing for shutdown season or scaling up for a long-haul contract, we have the right products, services and the right team,” said Mr Whalley.

A Legacy of Reliability, Built in Australia

Established in 1997, Eagle Forklifts started as a small, family-run business and has grown into one of Australia’s most trusted suppliers and service providers of heavy lifting and access equipment. With a strong presence in Queensland and a deep understanding of remote and regional mining logistics, the company is known for delivering tailored equipment solutions with dependable aftersales support.

“Downtime is not an option in mining,” said Mr Whalley.

“Our goal is to offer the right machine for the job, backed by service that understand what it means to work in regional and remote conditions.”

A Smarter Lift for Mining’s Next Decade

Mining in Australia is shifting toward efficiency, sustainability and strategic technology use. That includes smarter logistics. With close to three decades of experience, a rugged and adaptable fleet and a deep commitment to regional service, Eagle Forklifts is helping to move mining forward — one lift at a time.

Click here to Learn More www.eagleforklifts.com.au