20 years of excellence

From its foundation as experts in materials science and field services, the team at HAWC — Hard As Wear Components — believes in a different approach to maintenance. The team challenges industry standards by making products extremely wear resistant to suit real world conditions, delivered with boots-on-the-ground support.

Its success stems from reducing costs for customers and building lasting relationships. HAWC is fully backed by FMS Group — an Australian company offering engineering support, maintenance labour, condition monitoring, installation and speciality services such as jacking and machining.

This year, backed by more than 20 years of mining industry experience working on ultra-class excavators and shovels, FMS Group developed HAWC.

Combining advanced material engineering, precision design and cutting-edge heat treatment technology, HAWC delivers durable, high-performance wear components for mining and heavy industry applications. Offering a full suite of wear components under one roof, HAWC products are engineered to withstand the toughest conditions.

Specifically designed to enhance the efficiency and lifespan of equipment in the mining and industrial sectors, from undercarriage parts for excavators and shovels to milling and fixed plant solutions, HAWC sets the standard for reliability, durability and excellence. Supported by FMS Group’s multi-faceted business offerings, HAWC forms part of an end-to-end solution for clients.

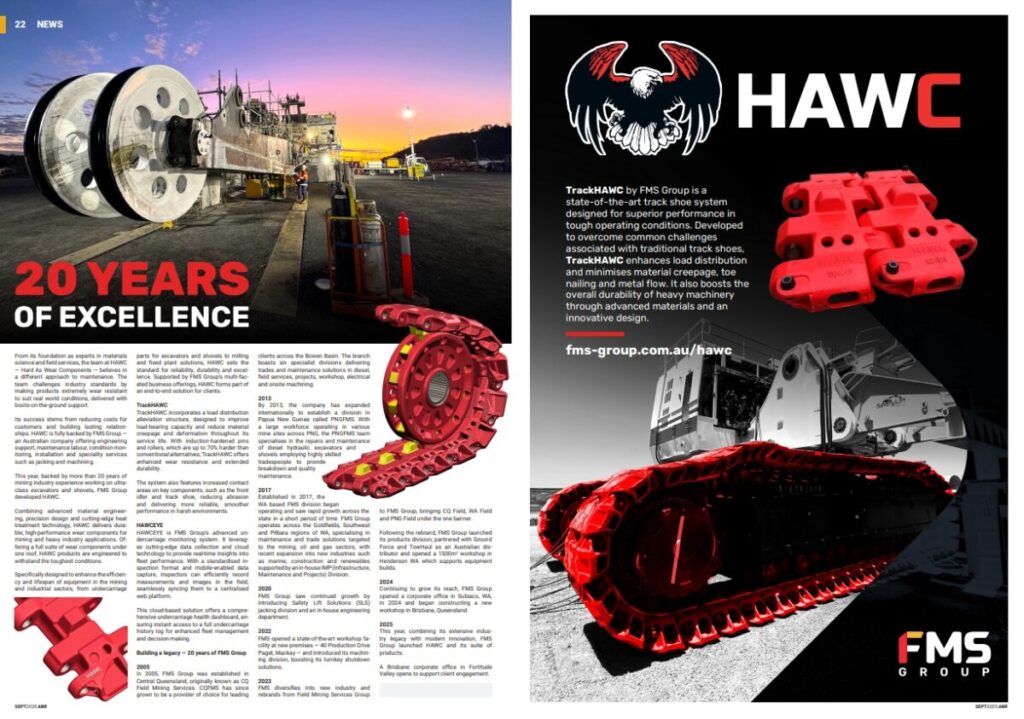

TrackHAWC

TrackHAWC incorporates a load distribution alleviation structure, designed to improve load-bearing capacity and reduce material creepage and deformation throughout its service life. With induction-hardened pins and rollers, which are up to 70% harder than conventional alternatives, TrackHAWC offers enhanced wear resistance and extended durability.

The system also features increased contact areas on key components, such as the front idler and track shoe, reducing abrasion and delivering more reliable, smoother performance in harsh environments.

HAWCEYE

HAWCEYE is FMS Group’s advanced undercarriage monitoring system. It leverages cutting-edge data collection and cloud technology to provide real-time insights into fleet performance. With a standardised inspection format and mobile-enabled data capture, inspectors can efficiently record measurements and images in the field, seamlessly syncing them to a centralised web platform.

This cloud-based solution offers a comprehensive undercarriage health dashboard, ensuring instant access to a full undercarriage history log for enhanced fleet management and decision-making.

Building a legacy — 20 years of FMS Group

2005

In 2005, FMS Group was established in Central Queensland, originally known as CQ Field Mining Services. CQFMS has since grown to be a provider of choice for leading clients across the Bowen Basin. The branch boasts six specialist divisions delivering trades and maintenance solutions in diesel, field services, projects, workshop, electrical and onsite machining.

2013

By 2013, the company has expanded internationally to establish a division in Papua New Guinea called PNGFMS. With a large workforce operating in various mine sites across PNG, the PNGFMS team specialises in the repairs and maintenance of diesel hydraulic excavators and shovels employing highly skilled tradespeople to provide breakdown and quality maintenance.

2017

Established in 2017, the WA based FMS division began operating and saw rapid growth across the state in a short period of time. FMS Group operates across the Goldfields, Southwest and Pilbara regions of WA, specialising in maintenance and trade solutions targeted to the mining, oil and gas sectors, with recent expansion into new industries such as marine, construction and renewables supported by an in-house IMP (Infrastructure, Maintenance and Projects) Division.

2020

FMS Group saw continued growth by introducing Safety Lift Solutions (SLS) jacking division and an in-house engineering department.

2022

FMS opened a state-of-the-art workshop facility at new premises — 40 Production Drive Paget, Mackay — and introduced its machining division, boosting its turnkey shutdown solutions.

2023

FMS diversifies into new industry and rebrands from Field Mining Services Group to FMS Group, bringing CQ Field, WA Field and PNG Field under the one banner.

Following the rebrand, FMS Group launched its products division, partnered with Ground Force and TowHaul as an Australian distributor and opened a 1500m2 workshop in Henderson WA which supports equipment builds.

2024

Continuing to grow its reach, FMS Group opened a corporate office in Subiaco, WA, in 2024 and began constructing a new workshop in Brisbane, Queensland.

2025

This year, combining its extensive industry legacy with modern innovation, FMS Group launched HAWC and its suite of products.

A Brisbane corporate office in Fortitude Valley opens to support client engagement.