Cape-ital gains

Amrun’s investment in the future of bauxite

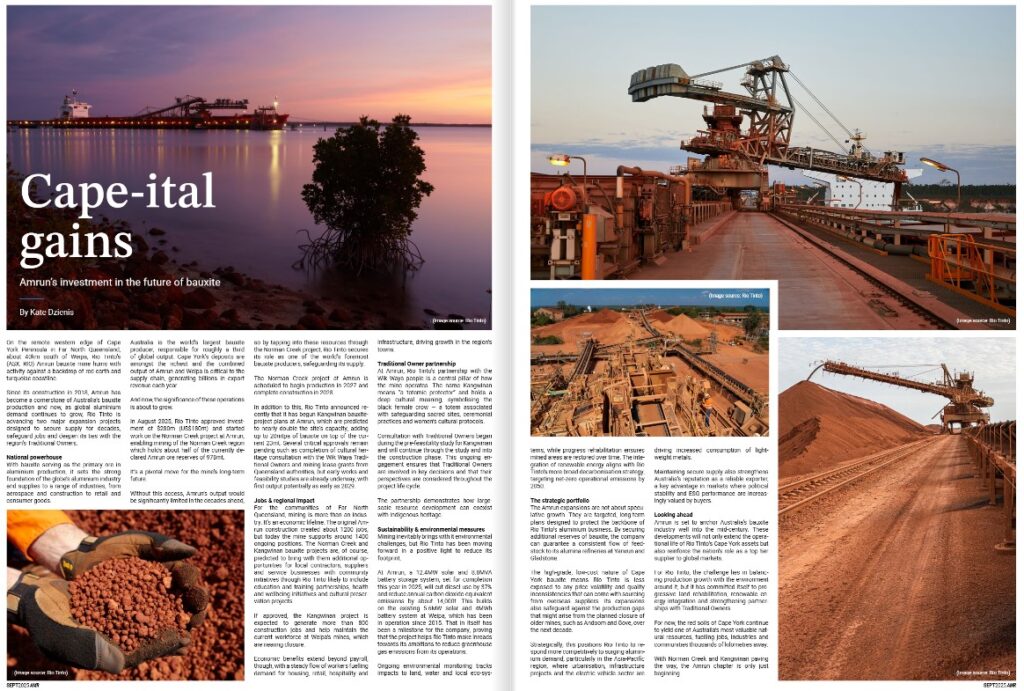

On the remote western edge of Cape York Peninsula in Far North Queensland, about 40km south of Weipa, Rio Tinto’s (ASX: RIO) Amrun bauxite mine hums with activity against a backdrop of red earth and turquoise coastline.

Since its construction in 2018, Amrun has become a cornerstone of Australia’s bauxite production and now, as global aluminium demand continues to grow, Rio Tinto is advancing two major expansion projects designed to secure supply for decades, safeguard jobs and deepen its ties with the region’s Traditional Owners.

National powerhouse

With bauxite serving as the primary ore in aluminium production, it sets the strong foundation of the globe’s aluminium industry and supplies to a range of industries, from aerospace and construction to retail and consumer goods.

Australia is the world’s largest bauxite producer, responsible for roughly a third of global output. Cape York’s deposits are amongst the richest and the combined output of Amrun and Weipa is critical to the supply chain, generating billions in export revenue each year.

And now, the significance of these operations is about to grow.

In August 2025, Rio Tinto approved investment of $180m and started work on the Norman Creek project at Amrun, enabling mining of the Norman Creek region which holds about half of the currently declared Amrun ore reserves of 978mt.

It’s a pivotal move for the mine’s long-term future.

Without this access, Amrun’s output would be significantly limited in the decades ahead, so by tapping into these resources through the Norman Creek project, Rio Tinto secures its role as one of the world’s foremost bauxite producers, safeguarding its supply.

The Norman Creek project at Amrun is scheduled to begin production in 2027 and complete construction in 2028.

In addition to this, Rio Tinto announced recently that is has begun Kangwinan bauxite project plans, which are predicted to nearly double Amrun’s capacity, adding up to 20mtpa of bauxite on top of the current 23mt. Several critical approvals remain pending such as completion of cultural heritage consultation with the Wik Waya Traditional Owners and mining lease grants from Queensland authorities, but early works and feasibility studies are already underway, with first output potentially as early as 2029.

Jobs & regional impact

For the communities of Far North Queensland, mining is more than an industry. It’s an economic lifeline. The original Amrun construction created about 1200 jobs, but today the mine supports around 1400 ongoing positions. The Norman Creek and Kangwinan bauxite projects are, of course, predicted to bring with them additional opportunities for local contractors, suppliers and service businesses with community initiatives through Rio Tinto likely to include education and training partnerships, health and wellbeing initiatives and cultural preservation projects.

Economic benefits extend beyond payroll, though, with a steady flow of workers fuelling demand for housing, retail, hospitality and infrastructure, driving growth in the region’s towns.

Traditional Owner partnership

At Amrun, Rio Tinto’s partnership with the Wik Waya people is a central pillar of how the mine operates. The name Kangwinan means “a totemic protector” and holds a deep cultural meaning, symbolising the black female crow — a totem associated with safeguarding sacred sites, ceremonial practices and women’s cultural protocols.

At Weipa, Rio Tinto works side-by-side with the Wik Waya people to select and propagate ancient seed varieties that hold ecological, medicinal and ceremonial value. These plants help re-establish native ecosystems, but they also ensure the cultural identity of the land is protected for future generations.

The partnership demonstrates how large-scale resource development can coexist with Indigenous heritage.

Sustainability & environmental measures

Mining inevitably brings with it environmental challenges, but Rio Tinto has been moving forward in a positive light to reduce its footprint.

At Amrun, a 12.4MW solar and 8.8MVA battery storage system, set for completion this year in 2025, will cut diesel use by 37% and reduce annual carbon dioxide-equivalent emissions by about 14,000t. This builds on the existing 5.6MW solar and 4MWh battery system at Weipa, which has been in operation since 2015. That in itself has been a milestone for the company, proving that the project helps Rio Tinto make inroads towards its ambitions to reduce greenhouse gas emissions from its operations.

Ongoing environmental monitoring tracks impacts to land, water and local eco-systems, while progress rehabilitation ensures mined areas are restored over time. The integration of renewable energy aligns with Rio Tinto’s more broad decarbonisation strategy, targeting net-zero operational emissions by 2050.

The strategic portfolio

The Amrun expansions are not about speculative growth. They are targeted, long-term plans designed to protect the backbone of Rio Tinto’s aluminium business. By securing additional reserves of bauxite, the company can guarantee a consistent flow of feedstock to its alumina refineries at Yarwun and Gladstone.

The high-grade, low-cost nature of Cape York bauxite means Rio Tinto is less exposed to any price volatility and quality inconsistencies that can come with sourcing from overseas suppliers. Its expansions also safeguard against the production gaps that might arise from the planned closure of older mines, such as Andoom and Gove, over the next decade.

Strategically, this positions Rio Tinto to respond more competitively to surging aluminium demand, particularly in the Asia-Pacific region, where urbanisation, infrastructure projects and the electric vehicle sector are driving increased consumption of lightweight metals.

Maintaining secure supply also strengthens Australia’s reputation as a reliable exporter, a key advantage in markets where political stability and ESG performance are increasingly valued by buyers.

Looking ahead

Amrun is set to anchor Australia’s bauxite industry well into the mid-century. These developments will not only extend the operational life of Rio Tinto’s Cape York assets but also reinforce the nation’s role as a top tier supplier to global markets.

For Rio Tinto, the challenge lies in balancing production growth with the environment around it, but it has committed itself to progressive land rehabilitation, renewable energy integration and strengthening partnerships with Traditional Owners.

For now, the red soils of Cape York continue to yield one of Australia’s most valuable natural resources, fuelling jobs, industries and communities thousands of kilometres away.

With Norman Creek and Kangwinan paving the way, the Amrun chapter is only just beginning.