Conveyor Idler Failure got you (Shut)down?

Idler failure is one of the most costly and unpredictable issues facing bulk handling operations. Failed idlers form a belt damage risk, which can slice the belt along its entire length or bite chunks out of the contact surface, leading to a belt tear. Both belt tears (across the grain) and belt rips (along the grain) can bring your operation to an expensive standstill.

Further still, seized idlers are a major fire risk due to friction with the moving belt and have the potential of getting red hot. Stopping the idler in this condition can result in an open flame as the belt stops stationary on a red-hot roller. In the event this idler is not detected in this condition, the first warning of a potential issue is often smoke appearing over the horizon, as conveyors rarely have a source of fire detection along their length.

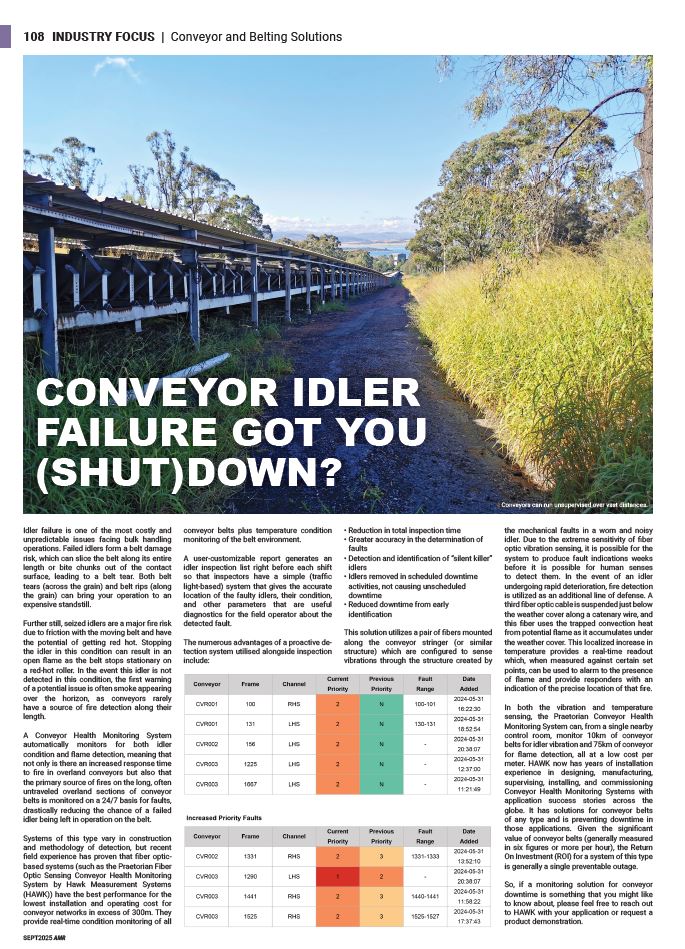

A Conveyor Health Monitoring System automatically monitors for both idler condition and flame detection, meaning that not only is there an increased response time to fire in overland conveyors but also that the primary source of fires on the long, often untraveled overland sections of conveyor belts is monitored on a 24/7 basis for faults, drastically reducing the chance of a failed idler being left in operation on the belt.

Systems of this type vary in construction and methodology of detection, but recent field experience has proven that fiber optic-based systems (such as the Praetorian Fiber Optic Sensing Conveyor Health Monitoring System by Hawk Measurement Systems) have the best performance for the lowest installation and operating cost for conveyor networks in excess of 300m. They provide real-time condition monitoring of all conveyor belts plus temperature condition monitoring of the belt environment.

A user-customizable report generates an idler inspection list right before each shift so that inspectors have a simple (traffic light-based) system that gives the accurate location of the faulty idlers, their condition, and other parameters that are useful diagnostics for the field operator about the detected fault.

The numerous advantages of a proactive detection system utilized alongside inspection include:

- Reduction in total inspection time

- Greater accuracy in the determination of faults

- Detection and identification of “silent killer” idlers

- Idlers removed in scheduled downtime activities, not causing unscheduled downtime

- Reduced downtime from early identification

This solution utilizes a pair of fibers mounted along the conveyor stringer (or similar structure) which are configured to sense vibrations through the structure created by the mechanical faults in a worn and noisy idler. Due to the extreme sensitivity of fiber optic vibration sensing, it is possible for the system to produce fault indications weeks before it is possible for human senses to detect them. In the event of an idler undergoing rapid deterioration, fire detection is utilized as an additional line of defense. A third fiber optic cable is suspended just below the weather cover along a catenary wire, and this fiber uses the trapped convection heat from potential flame as it accumulates under the weather cover. This localized increase in temperature provides a real-time readout which, when measured against certain set points, can be used to alarm to the presence of flame and provide responders with an indication of the precise location of that fire.

In both the vibration and temperature sensing, the Praetorian Conveyor Health Monitoring System can, from a single nearby control room, monitor 10km of conveyor belts for idler vibration and 75km of conveyor for flame detection, all at a low cost per meter. Hawk now has several years of installation experience in designing, manufacturing, supervising, installing, and commissioning Conveyor Health Monitoring Systems with application success stories across the globe. It has solutions for conveyor belts of any type and is preventing downtime in those applications. Given the significant value of conveyor belts (generally measured in six figures or more per hour), the Return on Investment (ROI) for a system of this type is generally a single preventable outage.

So, if a monitoring solution for conveyor downtime is something that you might like to know about, please feel free to reach out to Hawk Measurement Systems with your application or request a product demonstration.