Gold, gold, gold

Measuring ore grade on conveyors

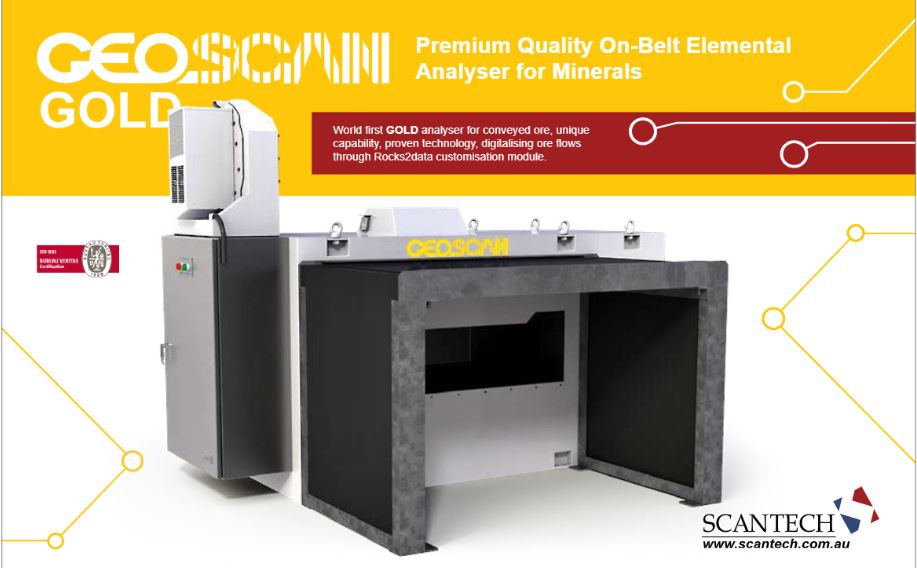

Scantech International’s GEOSCAN GOLD provides precise, direct gold measurement in conveyed primary crushed rock. It is the only one of its kind and becoming popular among leading gold producers.

Representative, precise and timely grade measurement in conveyed plant feed is combined with moisture and fragmentation data to provide new levels of plant control through improved ore management, early waste rejection, process improvements through reduced consumption of energy, water and reagents, and reduced fine tailings generation. Higher and more consistent feed grades result in higher metal recoveries and increased product for the same plant capacity generating major increases in revenue and reductions in costs. GHG emissions can be significantly reduced by processing less waste unnecessarily.

Primary crushed conveyed ore can be continuously measured in real time using high specification Prompt Gamma Neutron Activation Analysis (PGNAA). GEOSCAN is already proven in many challenging bulk ore sorting applications in base metals, industrial minerals and PGMs. GEOSCAN GOLD has been supplied to gold mines in North America, Latin America, Australia, Asia and Africa and is achieving expected performances. Leading gold companies are now measuring feed quality variability to develop a better understanding of its controls and consequences, and introducing systems to manage and improve it.

GEOSCAN GOLD measures a suite of elements over each 30 seconds of conveyed flow, including proxies for gold where available, as well as direct measurement of gold over 5-10 minute increments at precisions suitable for decision making (as low as 0.2 ppm Au). Decisions are made for ore blending changes, bulk increment diversion, and feed forward control. Measurement data is also used for metal accounting and ore reconciliation. The analyser measures elements in primary crushed rock in conveyed flows at <100 t/h to >10,000 t/h irrespective of belt speed, particle size, mineralogy, dust, moisture, or segregation/layering.

Digitalisation: Rocks2Data

Representative elemental analysis performance has been complemented with moisture and next-gen PSD analysis technologies. Scantech’s TBM200 series transmission microwave moisture analysers have proven the most reliable in the market with effective calibration within two days after commissioning. Ore reconciliation and metal accounting practices are improved with effective dry tonnage determination.

There is also strong interest in fragmentation data (particle size distribution – PSD) which the SizeScan produces using innovative 3D infrared camera technology and advanced proprietary algorithms. The SizeScan needs only a one off calibration after installation. Data from the SizeScan is produced every two seconds and transmitted directly to the plant control system and is owned by site without any access limitations or cost over its long life.

All Scantech analysers are supported through remote access which reduces customer costs. None of the systems have wear components and mechanical maintenance is virtually eliminated. Ongoing support is offered via qualified Scantech service engineers in each region backed up by a centrally located team of specialist calibration staff.

ESG

Measuring conveyed flow quality in real time can allow waste and low grade to be diverted from process feed, saving significant CO2 emissions from unnecessary processing and also reduces water, energy and reagent consumption and fine tailings generation.

Analysers in copper-gold and iron ore operations have proven successful in diverting short increments of flow (parcels) based on their quality, and some cut-off grade criteria effectively through an automated grade control to ensure the amount of waste processed is significantly reduced.

This in turn increases average feed quality and increases of 5 – 20+% have been achieved at a number of sites.

The process method can also benefit from product quality material bypassing unnecessary beneficiation in the case of iron ore where up to 33% of ore at one operation on average bypasses the jig plant.

Savings of 44,000t of CO2 emissions per year due to material diversion are being achieved. Analysers can be used at multiple stages in processing where material is conveyed and on waste flows. High sulphur waste can be separately stockpiled to inert waste to reduce acid drainage risk.

What to improve your process plant feed quality knowledge for incremental or step-change improvements? Contact us.