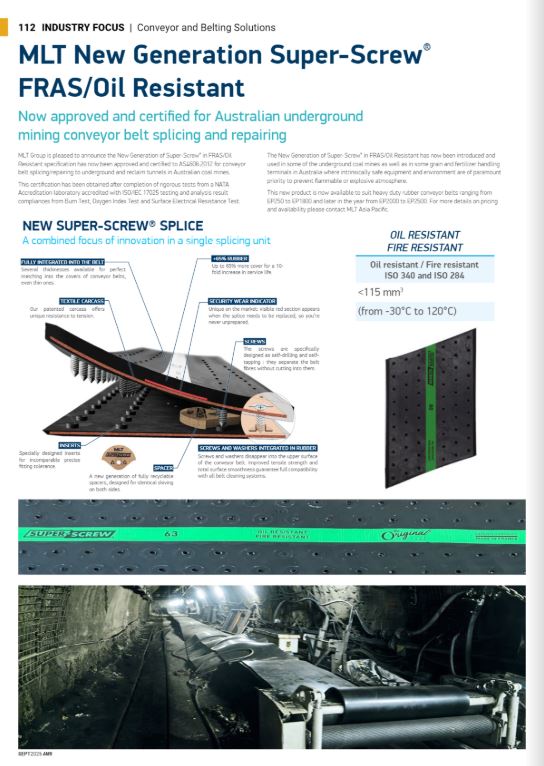

MLT New Generation Super-Screw® FRAS/Oil Resistant

Now approved and certified for Australian underground mining conveyor belt splicing and repairing

MLT Group is pleased to announce the New Generation of Super-Screw® in FRAS/Oil Resistant specification has now been approved and certified to AS4606:2012 for conveyor belt splicing/repairing to underground and reclaim tunnels in Australian coal mines.

This certification has been obtained after completion of rigorous tests from a NATA Accreditation laboratory accredited with ISO/IEC 17025 testing and analysis result compliances from Burn Test, Oxygen Index Test and Surface Electrical Resistance Test.

The New Generation of Super-Screw® in FRAS/Oil Resistant has now been introduced and used in some of the underground coal mines as well as in some grain and fertilizer handling terminals in Australia where intrinsically safe equipment and environment are of paramount priority to prevent flammable or explosive atmosphere.

This new product is now available to suit heavy duty rubber conveyor belts ranging from EP250 to EP1800 and later in the year from EP2000 to EP2500. For more details on pricing and availability please contact MLT Asia Pacific.