Titanium prospects

Avonbank mineral sands project

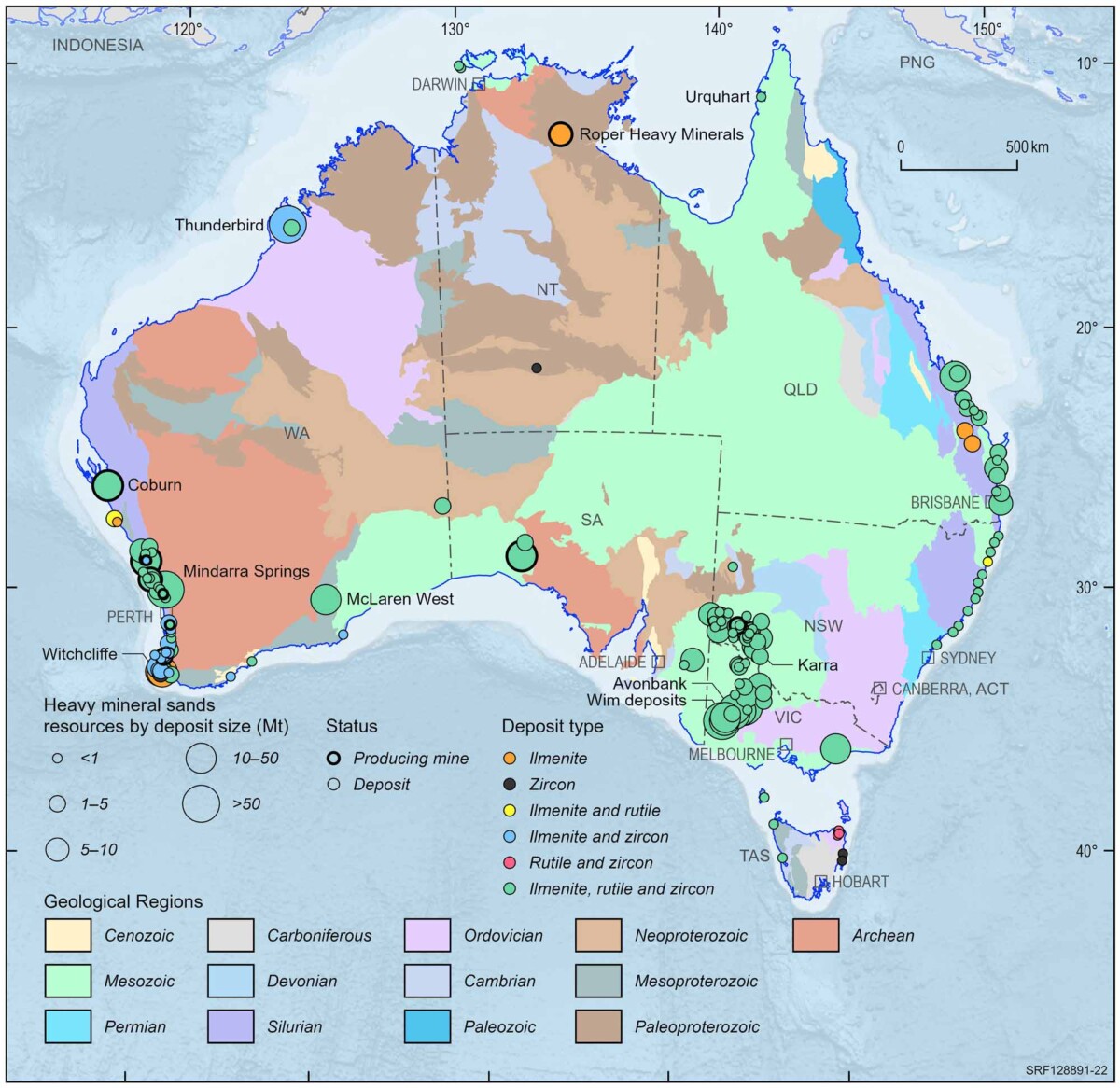

Overview: The Avonbank project is WIM Resource’s flagship project, with a proven and probable reserve of 311.8mt that underpins a 36-year project life. Avonbank is a tier one world-class zircon-rich heavy mineral sands project located near Horsham, Victoria.

10mtpa of ore will be mined from a shallow, low strip ratio, open pit mine using dry mining with a rapid rehabilitation method, that will return land back to its pre-mining state within four years

Status: WIM has completed successful phases of trial mining and trial demonstration-scale processing and rehabilitation. The Avonbank project definitive feasibility study completed in 2021 demonstrated attractive economics for the project. A favourable environmental effects statement (EES) assessment decision was provided in 2024, and Avonbank secondary approvals and engineering studies are on track to bring the project to a shovel-ready stage by late 2025. A trial mine & demonstration scale wet concentration plant has successfully confirmed that the ore is amenable to conventional mineral sands gravity separation to produce about 500ktpa heavy mineral concentrate containing zircon, titanium and rare earths elements (REE). Detailed downstream demonstration and product quality assessment trials have also been successfully completed.

Potential: When developed, Avonbank will be the single largest zircon mine in Victoria, and will be a tier one zircon mine globally, based on its mine life, with exceptional revenue to cost ratio and return on investment, according to WIM.

The Project will support nearly 1000 full time equivalent jobs, generate $15b in gross revenue and $3.5b to the gross state product. WIM welcomes discussions regarding product offtake or financing of Avonbank.

WIM has built a strong social and environmental license, having successfully rehabilitated the Avonbank trial mine within two years of mining, back to a productive broad acre agricultural crop.

Copi

Overview: RZ Resources is developing the world-class Copi critical minerals project in southwest NSW, along with an upgrade of its downstream mineral separation and processing plant (MSP) in Brisbane. RZ is pursuing a strategic drilling program with a clear strategy to build reserves and resources to support a mine life to 20 or more years.

Located in a tier one mining jurisdiction in the Murray Basin, the Copi project will use proven dredge mining of about 24mtpa ore to be processed on site using gravity separation to produce a heavy mineral concentrate with certain separated minerals (ilmenite (primary), ilmenite (secondary) and rare earths ready for direct export and other minerals being transported to RZ’s MSP, currently under care and maintenance.

Non-magnetic concentrate will be upgraded at the MSP to produce high-value products for export. The MSP (previously owned/operated by Sibelco and CRL) will be upgraded to produce high-grade titanium and zircon products for export.

Status: Attractive returns are demonstrated by the Copi definitive feasibility study (DFS) completed in January 2024, with enhancements expected by Q4 CY25. Environmental approvals are expected by early 2026 (environmental impact statement lodged with no significant environmental issues) and no Native Title issues identified. RZ has a large proportion of production under memorandum of understanding and is exploring offtake and strategic opportunities.

Potential: RZ’s strategic resource, combined with its integrated final-product processing capabilities provide a competitive advantage over industry peers.

Cyclone zircon project

Overview: The ‘shovel-ready’ Cyclone zircon project is considered one of a handful of major zircon-rich discoveries of the past decade, according to Diatreme Resources (ASX: DRX). The project has significant potential as one of the largest undeveloped, zircon-dominant heavy minerals projects in the world-class Eucla Basin with a 13.2-year mine life. The 2018 feasibility study was based on shallow free-dig mining using a bulldozer and dozer trap and progressive rehabilitation, with sand processed in an on-site wet concentrator via several stages of gravity concentration to produce a life of mine production of 1.94mt of heavy mineral concentrate (HMC), containing 936kt of zircon and including 772kt of final zircon product. The project is currently being re-evaluated based on the production and export of HMC.

Status: Following completion of a feasibility study on the Cyclone zircon project in 2018, metallurgical test work using the latest processing technologies is underway using bulk samples from recent drilling. The project is well advanced with primary approvals and permitting in place, including environmental and First Nations approvals.

Diatreme is engaging in discussions with a range of potential project partners including offtakers and technical partners, with the aim of either selling the project or funding development of this high-grade zircon project located in WA’s zircon-rich Eucla Basin.

Potential: Cyclone is an attractive investment opportunity amid the lack of suitable high-grade zircon supply, according to Diatreme. With shrinking zircon supply and rising demand, Cyclone is an attractive opportunity for a development partner to advance Australia’s zircon production for the global market, supporting the growth of this critical mineral industry.

Cyclone has the potential to become a significant global supplier of zircon, accounting for an estimated 6% of global zircon supply. The project also contains titanium minerals such as leucoxene, rutile and ilmenite and has potential for supply of the rare critical mineral hafnium within the zircon component of HMC

Medcalf

Overview: Audalia Resources (ASX: ACP) is developing the Medcalf project located 470km east of Perth, WA. The July 2022 pre-feasibility study (PFS) on the Medcalf project was based on mining about 1.5mtpa ore from three shallow (<50m depth) open-pit mines over an initial 6-year life, with no dewatering requirements.

Ore will be crushed and screened to produce about 975ktpa high grade titanium lump ore (HTLO) (10-60mm sizing) at 12.4% titanium dioxide, .7% vanadium oxide, and 59.2% iron oxide, with about 65% lump recovery. HTLO product will be trucked 220km to Esperance Port for export to Asian markets.

Status: A PFS completed in July 2022, demonstrated attractive economics for the project, with start-up capex of less than $40m.

In late-2024, a step out drilling program was completed, increasing strike length by about 250m with results pending. An infill drilling program focused on conversion of Inferred to indicated mineral resources is planned for 2025, along with geotechnical drilling.

The next step will be defining a maiden ore reserve targeting a 10-year mine life to support the updated PFS.

The project has a granted mining lease, environmental approval granted by the WA EPA in July 2024 and an agreement in place with the Traditional Owners.

Potential: Medcalf sample products have been sent to potential customers for testing and offtake discussions have commenced.