CTTW2025 highlights innovation and global partnerships

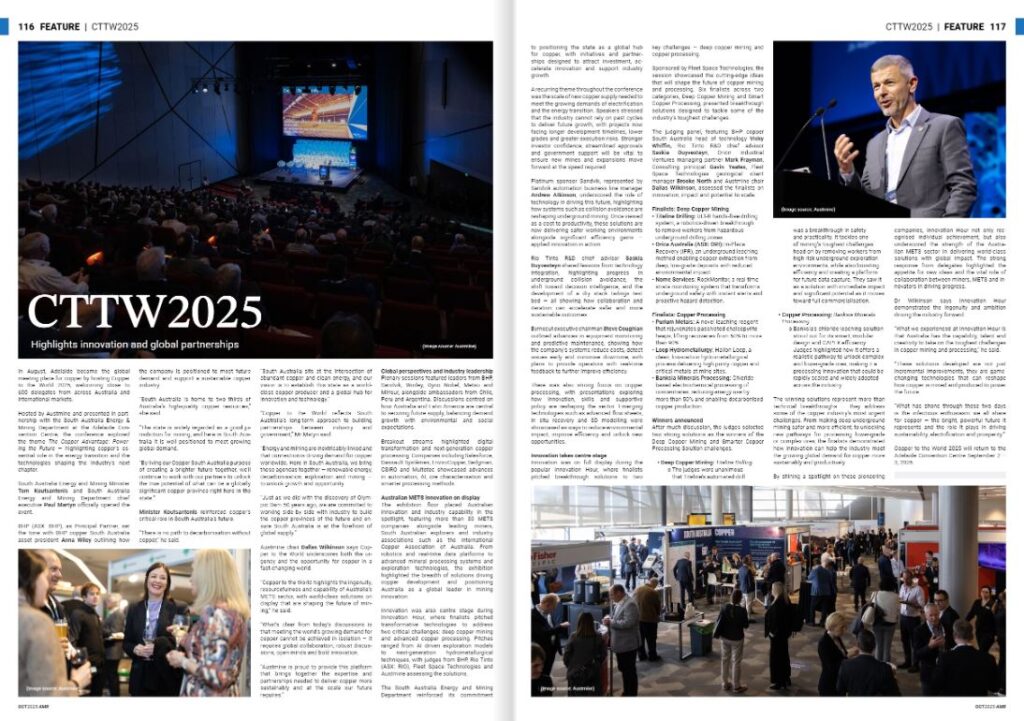

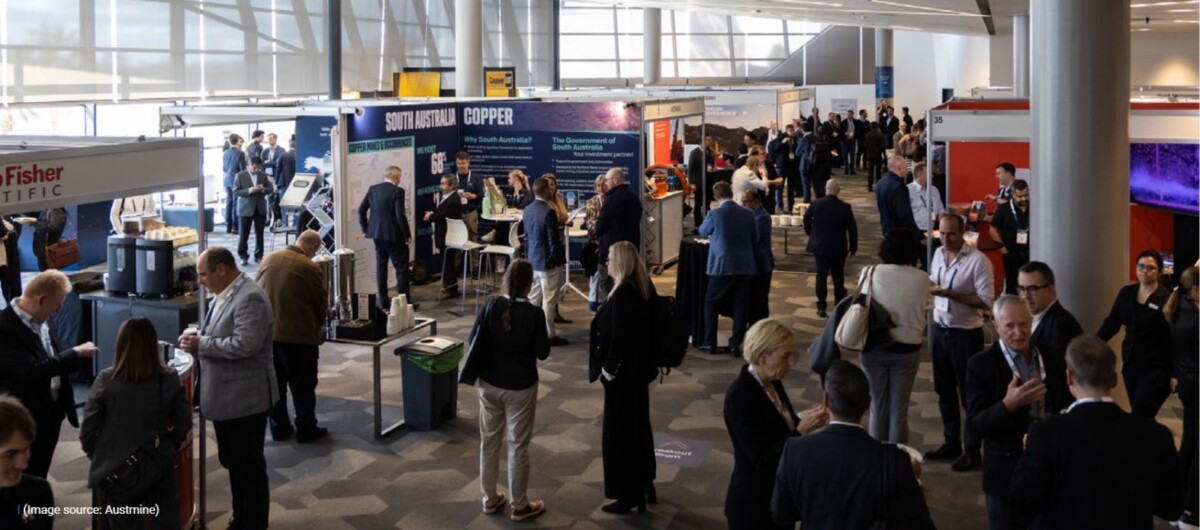

In August, Adelaide became the global meeting place for copper by hosting Copper to the World 2025, welcoming close to 600 delegates from across Australia and international markets.

Hosted by Austmine and presented in partnership with the South Australia Energy & Mining Department at the Adelaide Convention Centre, the conference explored the theme The Copper Advantage: Powering the Future — highlighting copper’s essential role in the energy transition and the technologies shaping the industry’s next chapter.

South Australia Energy and Mining Minister Tom Koutsantonis and South Australia Energy and Mining Department chief executive Paul Martyn officially opened the event.

BHP (ASX: BHP), as Principal Partner, set the tone with BHP copper South Australia asset president Anna Wiley outlining how the company is positioned to meet future demand and support a sustainable copper industry.

“South Australia is home to two thirds of Australia’s high-quality copper resources,” she said.

“The state is widely regarded as a good jurisdiction for mining, and here in South Australia it is well positioned to meet growing global demand.

“By living our Copper South Australia purpose of creating a brighter future together, we’ll continue to work with our partners to unlock the true potential of what can be a globally significant copper province right here in the state.”

Minister Koutsantonis reinforced copper’s critical role in South Australia’s future.

“There is no path to decarbonisation without copper,” he said.

“South Australia sits at the intersection of abundant copper and clean energy, and our vision is to establish this state as a world-class copper producer and a global hub for innovation and technology.”

“Copper to the World reflects South Australia’s long-term approach to building partnerships between industry and government,” Mr Matyn said.

“Energy and mining are inextricably linked and that connection is driving demand for copper worldwide. Here in South Australia, we bring those agendas together — renewable energy, decarbonisation, exploration and mining — to unlock growth and opportunity.

“Just as we did with the discovery of Olympic Dam 50 years ago, we are committed to working side by side with industry to build the copper provinces of the future and ensure South Australia is at the forefront of global supply.”

Austmine chair Dallas Wilkinson says Copper to the World underscores both the urgency and the opportunity for copper in a fast-changing world.

“Copper to the World highlights the ingenuity, resourcefulness and capability of Australia’s METS sector, with world-class solutions on display that are shaping the future of mining,” he said.

“What’s clear from today’s discussions is that meeting the world’s growing demand for copper cannot be achieved in isolation — it requires global collaboration, robust discussions, open minds and bold innovation.

“Austmine is proud to provide this platform that brings together the expertise and partnerships needed to deliver copper more sustainably and at the scale our future requires.”

Global perspectives and industry leadership

Plenary sessions featured leaders from BHP, Sandvik, Worley, Dyno Nobel, Metso and Minsur, alongside ambassadors from Chile, Peru and Argentina. Discussions centred on how Australia and Latin America are central to securing future supply, balancing demand growth with environmental and social expectations.

Breakout streams highlighted digital transformation and next-generation copper processing. Companies including Salesforce, Dassault Systèmes, EnviroCopper, Sedgman, CSIRO and Multotec showcased advances in automation, AI, ore characterisation and smarter processing methods.

Australian METS innovation on display

The exhibition floor placed Australian innovation and industry capability in the spotlight, featuring more than 30 METS companies alongside leading miners, South Australian explorers and industry associations such as the International Copper Association of Australia. From robotics and real-time data platforms to advanced mineral processing systems and exploration technologies, the exhibition highlighted the breadth of solutions driving copper development and positioning Australia as a global leader in mining innovation.

Innovation was also centre stage during Innovation Hour, where finalists pitched transformative technologies to address two critical challenges: deep copper mining and advanced copper processing. Pitches ranged from AI driven exploration models to next-generation hydrometallurgical techniques, with judges from BHP, Rio Tinto (ASX: RIO), Fleet Space Technologies and Austmine assessing the solutions

The South Australia Energy and Mining Department reinforced its commitment to positioning the state as a global hub for copper, with initiatives and partnerships designed to attract investment, accelerate innovation and support industry growth.

A recurring theme throughout the conference was the scale of new copper supply needed to meet the growing demands of electrification and the energy transition. Speakers stressed that the industry cannot rely on past cycles to deliver future growth, with projects now facing longer development timelines, lower grades and greater execution risks. Stronger investor confidence, streamlined approvals and government support will be vital to ensure new mines and expansions move forward at the speed required.

Platinum sponsor Sandvik, represented by Sandvik automation business line manager Andrew Atkinson, underscored the role of technology in driving this future, highlighting how systems such as collision avoidance are reshaping underground mining. Once viewed as a cost to productivity, these solutions are now delivering safer working environments alongside significant efficiency gains — applied innovation in action.

Rio Tinto R&D chief advisor Saskia Duyvesteyn shared lessons from technology integration, highlighting progress in underground collision avoidance, the shift toward decision intelligence, and the development of a dry stack tailings test bed — all showing how collaboration and iteration can accelerate safer and more sustainable outcomes.

Byrnecut executive chairman Steve Coughlan outlined advances in equipment monitoring and predictive maintenance, showing how the company’s systems reduce costs, detect issues early and minimise downtime, with plans to provide operators with real-time feedback to further improve efficiency.

There was also strong focus on copper processing, with presentations exploring how innovation, skills and supportive policy are reshaping the sector. Emerging technologies such as advanced flow sheets, in situ recovery and 3D modelling were showcased as ways to reduce environmental impact, improve efficiency and unlock new opportunities

Innovation takes centre stage

Innovation was on full display during the popular Innovation Hour, where finalists pitched breakthrough solutions to two key challenges — deep copper mining and copper processing.

Sponsored by Fleet Space Technologies, the session showcased the cutting-edge ideas that will shape the future of copper mining and processing. Six finalists across two categories, Deep Copper Mining and Smart Copper Processing, presented breakthrough solutions designed to tackle some of the industry’s toughest challenges.

The judging panel, featuring BHP copper South Australia head of technology Vicky Whiffin, Rio Tinto R&D chief advisor Saskia Duyvesteyn, Orion Industrial Ventures managing partner Mark Frayman, Consulting principal Gavin Yeates, Fleet Space Technologies geological client manager Brooke North and Austmine chair Dallas Wilkinson, assessed the finalists on innovation, impact and potential to scale.

Finalists: Deep Copper Mining

- Titeline Drilling: ULT-R hands-free drilling system, a robotics-driven breakthrough to remove workers from hazardous underground drilling zones.

- Orica Australia (ASX: ORI): In-Place Recovery (IPR), an underground leaching method enabling copper extraction from deep, low-grade deposits with reduced environmental impact.

- Nome Services: RockMonitor, a real-time strata monitoring system that transforms underground safety with instant alerts and proactive hazard detection.

Finalists: Copper Processing

- Purium Metals: A novel leaching reagent that rejuvenates passivated chalcopyrite heaps, lifting recoveries from 50% to more than 90%.

- Loop Hydrometallurgy: Halion Loop, a clean, low-carbon hydrometallurgical process delivering high purity copper and critical metals at mine sites.

- Banksia Minerals Processing: Chloride-based electrochemical processing of concentrates, reducing energy use by more than 50% and enabling decarbonised copper production.

Winners announced

After much discussion, the judges selected two strong solutions as the winners of the Deep Copper Mining and Smarter Copper Processing Solution challenges.

- Deep Copper Mining: Titeline Drilling

- The judges were unanimous that Titeline’s automated drill was a breakthrough in safety and practicality. It tackles one of mining’s toughest challenges head-on by removing workers from high-risk underground exploration environments, while also boosting efficiency and creating a platform for future data capture. They saw it as a solution with immediate impact and significant potential as it moves toward full commercialisation.

- Copper Processing: Banksia Minerals Processing

- Banksia’s chloride leaching solution stood out for its smart, modular design and CAPEX efficiency. Judges highlighted how it offers a realistic pathway to unlock complex and lower-grade ores, making it a processing innovation that could be rapidly scaled and widely adopted across the industry.

The winning solutions represent more than technical breakthroughs — they address some of the copper industry’s most urgent challenges. From making deep underground mining safer and more efficient, to unlocking new pathways for processing lower-grade or complex ores, the finalists demonstrated how innovation can help the industry meet the growing global demand for copper more sustainably and productively.

By shining a spotlight on these pioneering companies, Innovation Hour not only recognised individual achievement, but also underscored the strength of the Australian METS sector in delivering world-class solutions with global impact. The strong response from delegates highlighted the appetite for new ideas and the vital role of collaboration between miners, METS and innovators in driving progress.

Dr Wilkinson says Innovation Hour demonstrated the ingenuity and ambition driving the industry forward.

“What we experienced at Innovation Hour is that Australia has the capability, talent and creativity to take on the toughest challenges in copper mining and processing,” he said.

“These solutions developed are not just incremental improvements, they are game-changing technologies that can reshape how copper is mined and produced to power the future.

“What has shone through these two days is the infectious enthusiasm we all share for copper — the bright, powerful future it represents and the role it plays in driving sustainability, electrification and prosperity.”

Copper to the World 2025 will return to the Adelaide Convention Centre September 2 – 3, 2026.