Advanced Navigation’s autonomous mining breakthrough

Advanced Navigation’s Boreas D90 Inertial Navigation System (INS) and Laser Velocity Sensor (LVS) were successfully demonstrated at Europe’s deepest underground mine.

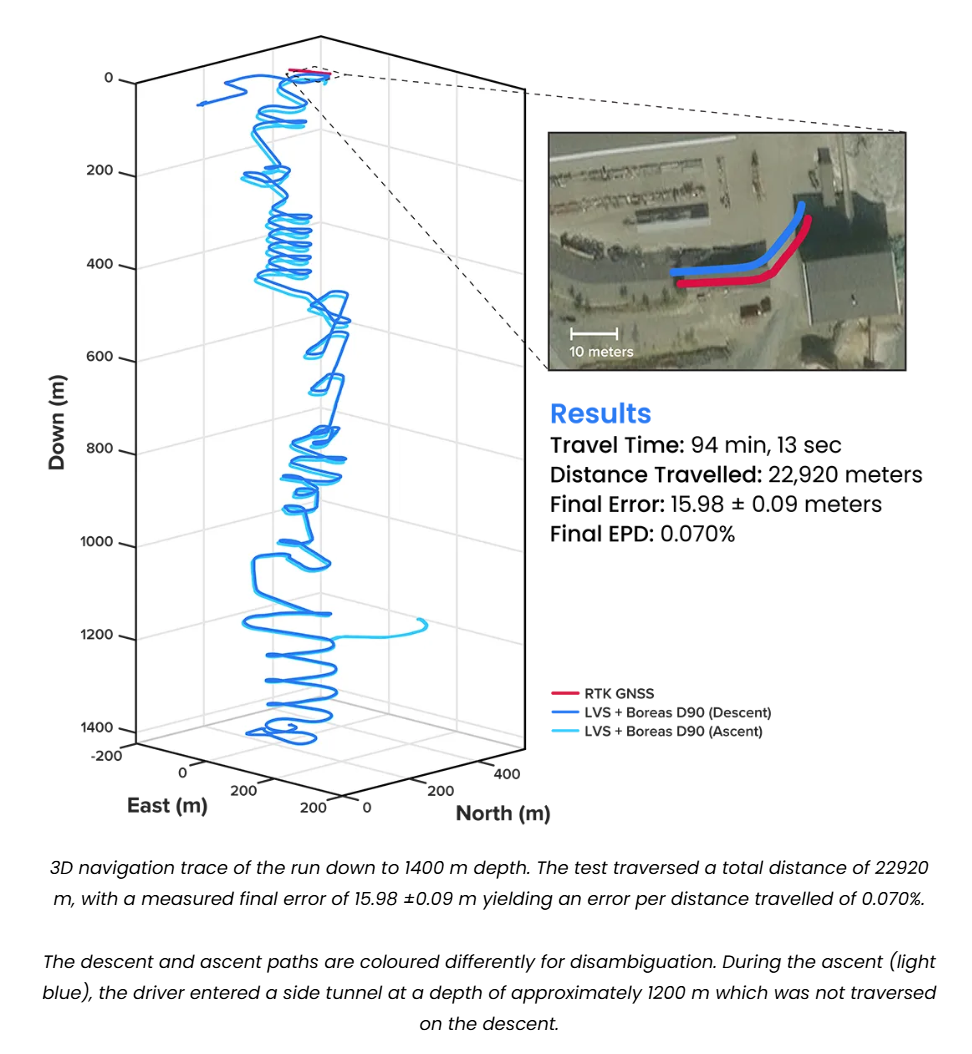

As part of BHP’s (ASX: BHP) deep mining challenge, the system was sent to the Pyhäsalmi zinc and copper mine in Finland and operated between 400m and 1,400m depth across 22km of tunnel.

The system maintained a position error of less than .1% of distance travelled and, in some instances, exceeded global navigation system (GNSS)-level accuracy.

The Hybrid Navigation System demonstrated long-range, infrastructure-free, real-time navigation in a deep, GPS-denied environment. A one-time surface calibration using RTK GNSS aligned the LVS and INS frames on a vehicle of opportunity, after which all trials were unaided within the underground environment.

Critical barriers to unlocking scalable autonomy within the mining sector include accurate real-time tracking, optimised haulage, predictive collision avoidance, material tracking, efficient ore extraction and tele-remote operations.

The successful results have consolidated the feasibility of fully autonomous mining in even the most challenging of environments that lack GNSS, fixed infrastructure or accurate mapping — including mining at depths too hostile for a human workforce.

All tests were performed without prior knowledge of the mine layout, or the use of any existing infrastructure. Position accuracy was maintained across all axes, with consistent performance across depth, loop closure and initialisation scenarios.

This performance marks a step change in underground navigation, unlocking new potential for fleet management, material tracking and scalable autonomy across underground mining operations.

Advanced Navigation senior product manager Joe Vandecar says unreliable navigation underground isn’t a minor technical constraint — it’s a major operational bottleneck.

“Maintaining precision over a 22.9km subterranean course in Europe’s deepest underground mine demonstrates a level of performance that few systems in the world can rival without any prior intelligence of the environment,” he said.

“These results prove we’re one step closer to unlocking scalable underground autonomy.”

While mines will continue to use fixed infrastructure, this technology significantly reduces dependency, enabling resilient, high-precision navigation in previously inaccessible or unmapped areas.

“Ultimately, this vehicle-based, inertial-centred architecture provides the resilient foundation required for the mining sector to achieve its long-term goal — efficient autonomous ore extraction at depths hostile to human activity,” Mr Vandecar said.

The system is anticipated to be commercially available in late 2025.