Open-cut mines find themselves at the mercy of changes in weather. The effectiveness of noise, vibration, dust and air quality monitoring can be the difference between continuing or suspending operations.

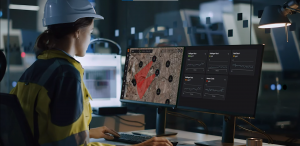

Today’s mining assets require highly accurate data and deep insights about changing environmental conditions to allow operators to use active situational awareness and make better informed decisions at any time.

Envirosuite is one company helping mines and heavy industrial operations unlock hidden asset value, while improving quality of life for both their workforce, and neighbouring communities.

As a pioneer in environmental management software, the company delivers real-time data modelling solutions that allow mines to forecast weather risk, plan blasting activities ahead of time, drive efficiency gains, and maintain environmental compliance.

Noise and vibration are two relatively complex risks associated with mining and industrial activities, which can lead to structural damage, operational stoppages, and regulatory fines, if unmanaged.

With over 40 years in applied noise and vibration management, it’s no surprise the company’s intelligent monitoring systems keep mines productive and profitable, without exceeding thresholds.

The Australian Mining Review recently caught up with Envirosuite’s Phil Stollery, Head of Environmental Intelligence Services, and Andres Quijano, Solution Design Engineer, to learn more about their revolutionary noise and vibration monitoring technology.

AMR: Can you tell me a little more about noise and vibration monitoring in the mining industry?

PS: Firstly, we’re a global company that services mines all over the world. Our mining customers all have one thing in common, and that’s how to manage noise and vibration to optimise operations while remaining compliant.

These are highly applicable in mining, particularly during blasting activities which can cause excessive ground vibration and blast overpressure in the air.

A great deal of planning is involved in blasting. The placement of charges is very important as it dictates the desired vibration response. So, vibration comes down to how to best optimise the blasting process, while minimising the environmental impact. You need consider surrounding communities and infrastructure.

Aside from optimising blasts, we provide both monitoring and predictive modelling of blast waves, which offers unique insight into its potential impact.

This impact is two-fold. First, the vibration wave traveling through the ground, potentially creates structural damage and through rattling windows for example, nuisance. Second, the airborne acoustic response, which is the blast overpressure. This is critical in mining due to the propagation of that overpressure, depending on weather conditions it can reflect back to ground rather than disperse. You can end up with an unexpected pattern when a blast occurs, and there’s no impact close to the mine. But, further out, it can cause nuisance and damage.

Essentially, the blast process is planned around the vibration wave, both from a blast optimisation perspective, but also in managing the potential impact from overpressure based on weather conditions.

So, weather conditions are key to whether blasting can be undertaken, and what type of blasting is selected. We leverage a suite of tools to support predictions, including a mix of both software and hardware.

AMR: What are some of the tools or technologies the company uses?

PS: We use modelling to predict the blast overpressure, and the vibration wave to ensure the projected impact will be suitable with respect to nearby people, buildings and sensitive receptors. Our systems will alert them as to what the expected impact will be in terms of noise and vibration based on the planned blast parameters and hyper local forecast weather conditions.

In the case of overpressure where the wave travels in ambient air, as weather conditions vary during the day, they change the refraction of that wave, particularly temperature inversions and wind conditions. If the model shows unfavourable prorogation than blasting can be postponing to a more favourable day/time.

We have forecasting metrological models that are run hourly to better understand the forecast for the scheduled blast time.

That’s the predictive side of things, and obviously where we want to add the most value. In doing so, we can actually avoid significant environmental risks.

AMR: Aside from predictive modelling, is there a secret to effective noise and vibration monitoring?

PS: Absolutely. Although data models are great, they’re not always precise, so that’s where monitoring comes into play. Although our software can integrate within a site’s existing hardware, we do actually supply dedicated monitoring terminals for use in noise and vibration monitoring. First, our permanent and portable noise monitoring terminals collect data in real-time. They capture noise data accurately and reliably, and can be operated by anyone needing to monitor noise levels and demonstrate regulatory compliance.

First, our permanent and portable noise monitoring terminals collect data in real-time. They capture noise data accurately and reliably, and can be operated by anyone needing to monitor noise levels and demonstrate regulatory compliance.

The same applies to vibration monitoring where we have terminals that offer accurate, uninterrupted monitoring of vibration levels. Each unit is designed for users to reduce the risk of structural damage, equipment failure and physical harm from excessive vibration.

The idea is to position the noise and vibration terminals in different locations around a mine. Aside from measuring vibration and overpressure in blasting, we typically position the monitors near sensitive receptors such as community buildings, hospitals or places that require protection. We can then use the collected data, and tune it the digital modelling as required.

The data tells us whether there was a breach, or if more noise and vibration than expected occurred at those specific locations, such as building damage or stakeholder complaints. We can also use this data to demonstrate that we didn’t create any subsequent noise or vibration events.

If we’re handling blast-related complaints from the community, then we can accurately report that blasting was carried out in a controlled manner, and any noise or vibrations were within regulatory thresholds.

Essentially, data insights help drive meaningful discussions with communities and stakeholders to show the mine is aware of its impact, and is taking effective measures to reduce its impact to acceptable or agreed levels.

AMR: What problems can arise in noise and vibration monitoring that impact mining?

PS: Blast waves can travel long distances, and in some cases we’re monitoring noise and vibration kilometres away from the actual blast site.

It’s not just about blasting. There are many other sources of noise and vibration in a mine. Noise disturbance is caused by earthmoving machinery, rock crushers, and even railway tracks and conveyors transporting material.

While levels are typically lower than blasting, these activities can be more of an issue as they generate constant noise rather than short bursts at specific time periods as in blasting.

Monitoring captures all sources of noise and vibration though, not just mining noise. It’s a real challenge to identify whether excessive noise and vibration are from mining activities, or if other sources are at play. In many cases regulations require us to monitor at the boundary of a mine – this can be several km from mining noise sources and adjacent to often much louder community noise sources such as road traffic.

We use analytics to determine if a noise or vibration is from the community background activity or the mine. If additional monitoring close to mining sources isn’t indicating mining activity, then clearly measurements in the community must be background. A more sophisticated approach is to look at the temporal and frequency characteristics of the measured noise and vibration classifying as background those that don’t match expected mining activity. This happens automatically in our system and ensures that mines are not penalised for exceedances that are not their responsibility.

AMR: Is there more of a focus in these areas lately because of ESG legislation?

AQ: Mining operations in particular can have a significant impact on surrounding neighbourhoods, buildings and infrastructure. We obviously understand the difficulty of operating under strict licence conditions and thresholds.

When it comes to the legislation side of things, we have acoustics engineers, supported by Envirosuite noise monitors that are considered one of the best products on the market.

Solid raw data gives you the necessary insights and ability to alter particular elements to ensure noise and vibration levels meet regulatory requirements. We want to be able to monitor vibration and noise at the same time. If we model a blast design as an example, although operators will only perform a blast on a specific day and time window, we would permanently position monitors throughout a mine. This allows us to create a workflow and gives the environmental team input in the planning and production process.

If we model a blast design as an example, although operators will only perform a blast on a specific day and time window, we would permanently position monitors throughout a mine. This allows us to create a workflow and gives the environmental team input in the planning and production process.

This real-time data benefits the mine and blasting as the environmental team can analyse and forecast patterns, then advise what the best blast window will be based on the conditions.

AMR: How do your monitoring solutions benefit customers from a compliance perspective?

AQ: As mine operations move closer to growing communities, there is an inherent risk of breaching environmental compliance regulations.

From an environmental point of view, mines need to future proof their operations, particularly to keep up with the changes in noise and vibration compliance obligations.

So, it’s our job to help them optimise the outcomes of their onsite blasting activities, minimise environmental risk and improve transparency. Whether it’s predictive insights or hyperlocal weather forecasting, real-time data is critical.

It’s essentially a matter of balancing production goals, community expectations, and regulatory compliance through situational awareness. Our real-time software solutions provide the valuable insight operations need to plan and respond quickly to limit any potential breaches and stoppages.

AMR: With so much at stake when it comes to managing a mining asset, it’s only logical that companies look to technology providers like Envirosuite. With proven noise and vibration monitoring, combined with mining environmental management solutions, it’s time to future proof your operation today.

To learn more about Envirosuite’s range of noise and vibration monitoring solutions, visit https://envirosuite.com/industries/mining