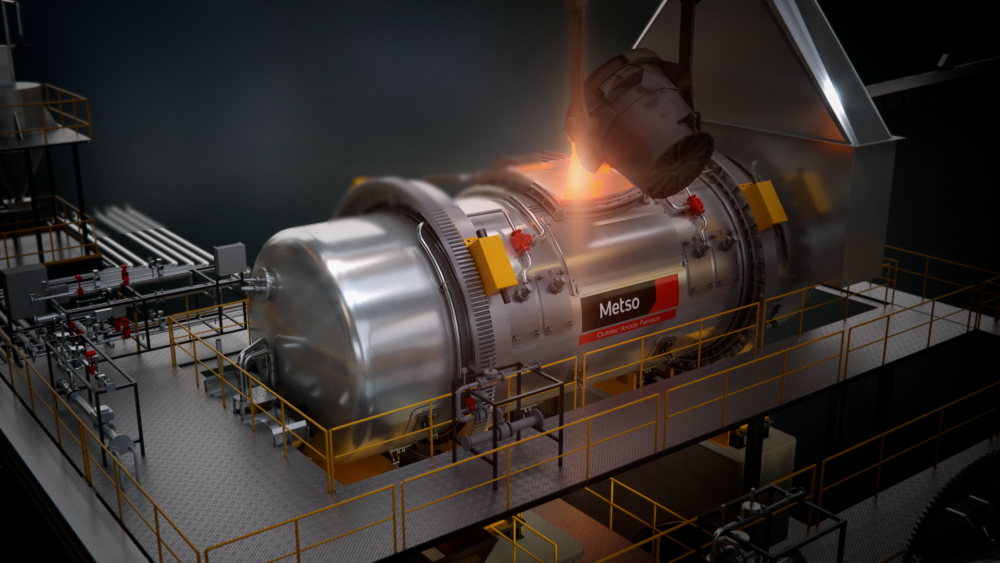

Metso launches modernised anode furnace

Metso is launching a next-generation Anode Furnace for reducing carbon dioxide emissions, improving impurity removal capabilities and bringing flexibility in treating secondary materials.

The upgraded Anode Furnace features the latest design, advances in process safety, and ease of maintenance. It also presents two exciting methods for reducing carbon dioxide emissions.

Metso anode casting and anode furnace technologies senior sales manager Miikka Marjakoski says this makes the new Anode Furnace unique.

“The process is fully prepared to utilise direct hydrogen reduction in the H2-ready variant,” he said.

“However, if the customer has no opportunity to switch to hydrogen use at present, Metso can also provide the technology to significantly increase the current gaseous hydrocarbon reductant efficiency with a steam-gas reduction system.

“Combining this with Oxyfuel combustion at the burners, the total reduction in carbon dioxide emissions is demonstrably significant compared with traditional processes. This has also been proved through LCA calculations.

“Raw materials pose both great challenges and opportunities for copper smelters today.

“Whether it is bringing in new primary concentrates, utilising existing ones with degrading quality, or integrating secondary raw materials into existing processes, the demand for flexibility in the unit processes is growing.

“At the same time, the smelters are looking to identify potential reduction sources for greenhouse emissions, while the evolving raw material base is not making this paramount task easier.

“Metso’s Outotec® Anode Furnace is a great fit for solving these challenges.

“With its innovative carbon dioxide emissions reduction solutions, improved impurity removal capabilities and the flexibility to treat secondary materials, it brings the long-trusted workhorse of the copper smelting industry into the modern era.”

The Anode Furnace delivery scope consists of all key equipment required for operating the furnace.

Metso’s Scrap Melting Furnace variant of the Anode Furnace presents further opportunity to treat a substantial amount secondary raw materials by utilising integrated burners for melting purposes.

“The Outotec® Scrap Melting Furnace yields great flexibility in treating any mixture of molten copper from upstream processes and high-grade secondary copper feed directly into the anode furnace,” Mr Marjakoski said.

“It can be used as a stand-alone melting furnace utilizing solely secondary raw materials, making the product a go-to choice for primary and secondary smelters alike.”