Safer underground mines with environmental monitoring systems

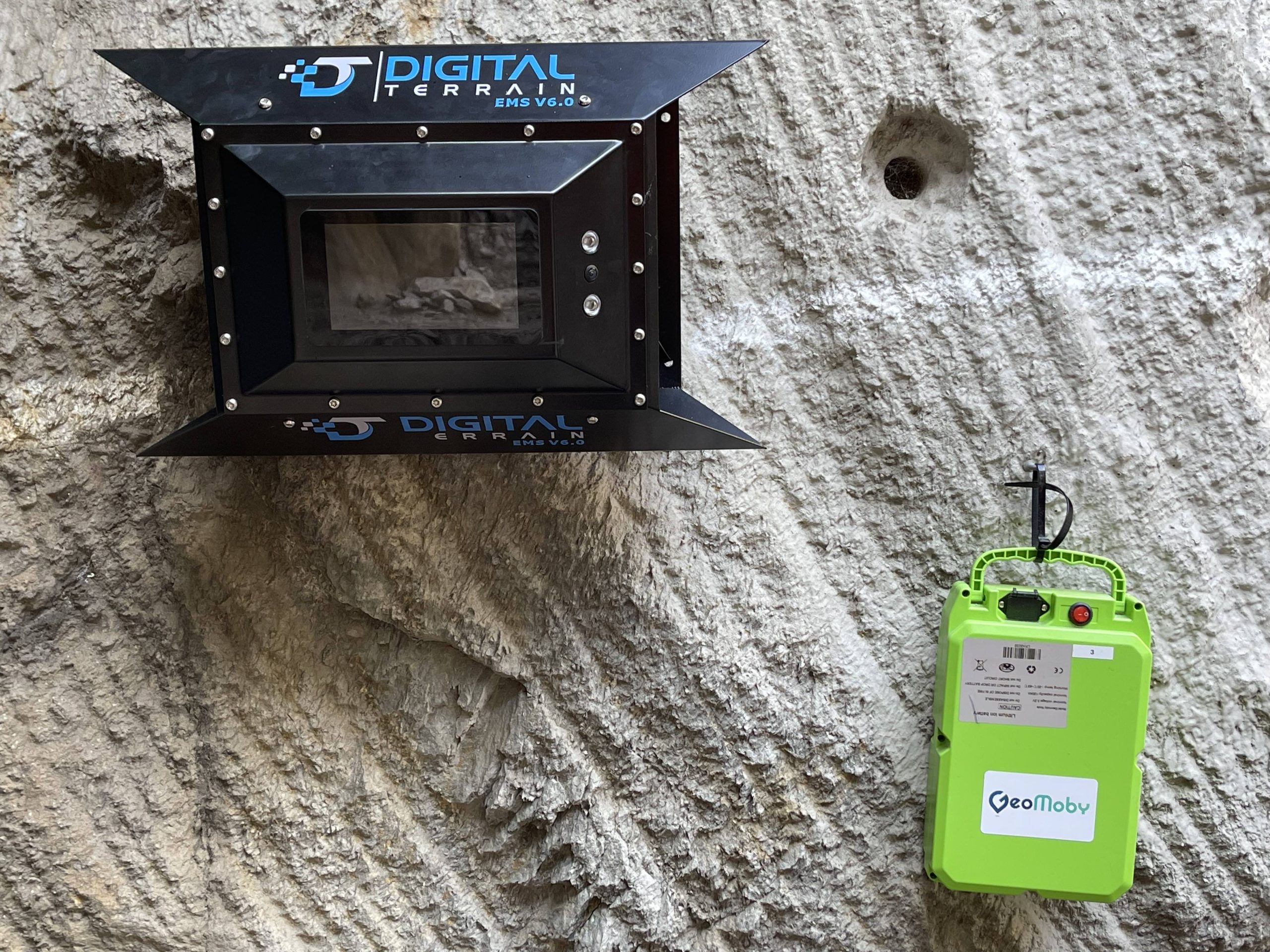

Australian mining location intelligence company GeoMoby has partnered with Sydney-based Digital Terrain to apply its real-time technology to monitoring environmental conditions in underground mines.

Underground conditions are hazardous and dangerous, with these fully-integrated technologies from GeoMoby and Digital Terrain providing environmental monitoring solutions that record a host of information, improving mining conditions and ultimately save lives.

GeoMoby director Mathieu Paul says temperature and potentially-lethal gases such as carbon monoxide or methane can easily be remotely monitored and recorded, with alerts triggered where required.

“Essentially Digital Terrain has the technology to monitor many conditions – from levels of gases, such as oxygen, to the temperature in underground mines – and GeoMoby has the technology to use Digital Terrain’s data, from its recording devices, to use that information to trigger alarms if necessary,” he said.

“We know this is the best, most accurate solution for environmental monitoring in underground mine sites in Australia right now.”

Mr Paul adds that both companies have successfully integrated their own solutions together, with the technology installed at several large Australian mines.

“For example, if Digital Terrain detects too much carbon monoxide or methane in the mine’s atmosphere, then GeoMoby real-time systems trigger alerts for management and an emergency response can be rolled out much faster and more efficiently,” he said.

GeoMoby chief executive and founder Chris Baudia says this is “another important adaption of our technology to help keep workers safe, so they can return to their families every single day”.

Digital Terrain’s RDI-EMS monitors temperature (wet and dry bulb), wide (speed and direction), humidity, gases and dust.

Gas sensors can detect oxygen, carbon monoxide, carbon dioxide, nitrogen dioxide, hydrogen sulphide, methane and ammonia.

It also detects a firing and sends a message to the blast crew when it is best to start conducting re-entries, saving valuable time, especially in single heading independent firing situations.

Underground Mine Collapse Inspires Technology

Mr Baudia was inspired to create GeoMoby’s technology more than a decade ago after hearing about an underground mine collapse in which lives were lost.

“Many underground mines – in WA and the world – still use employee monitoring systems that revolve around whiteboards, spreadsheets and tag boards,” he said.

“Mistakes concerning equipment and people can easily be made, especially at the change of shift crews or during an emergency.

“There are no excuses in 2023 – our technology can monitor workers at all times, making sure everyone returns home safely, every single day.

“It is a valuable, modern tool in the kitbag of any mine manager ensuring the health and safety of large teams, working underground.

“Companies always need to know where their people are underground otherwise – in an emergency – response times can lag.

“Too often, in underground mining, there can be an inability to quickly and accurately locate personnel involved in critical incidents so the relevant emergency response can be employed in a timely manner.”

GeoMoby has a patent for its underground location technology.