BarChip Fibre – Using Recycled Plastics in Deep Mine Ground Support System

Since BarChip introduced its R-Series fibre to market, they’ve recycled over 3,700 tonnes of plastic into mining ground support works, helping clients towards net zero in 2050.

The Mineral Council of Australia’s Climate Action Plan is working towards an ambitious target of net zero emissions by 2050. Achieving such a plan requires significant investment from all member companies within the mining industry.

A key initiative in the plan is the widespread deployment of low and zero emission technologies. A lot of attention is directed toward large-scale investments such as renewable energy, electrification and battery storage, but miners will need to look at low carbon technologies across their entire supply chain to meet the target and confirm their ESG credentials.

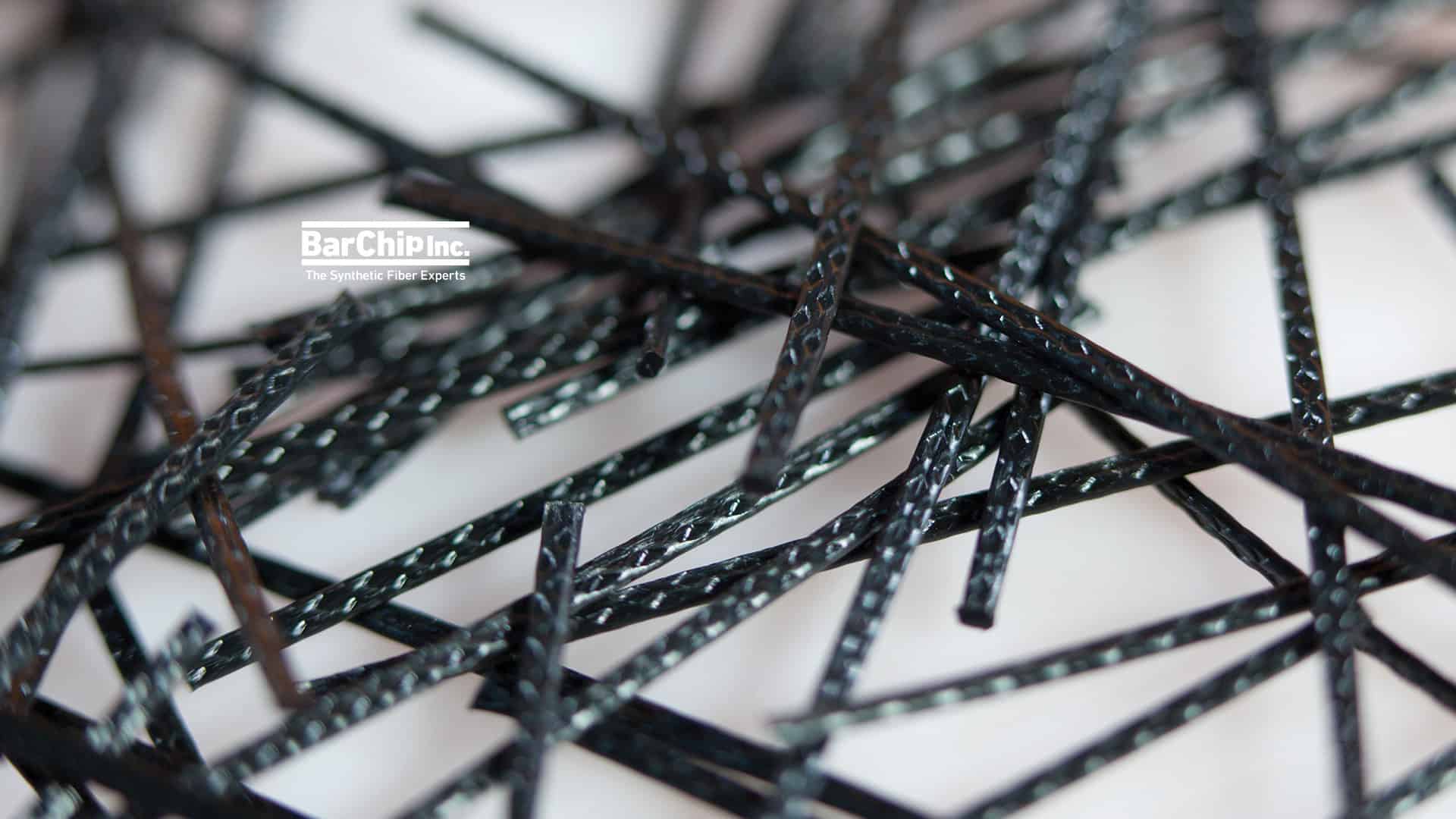

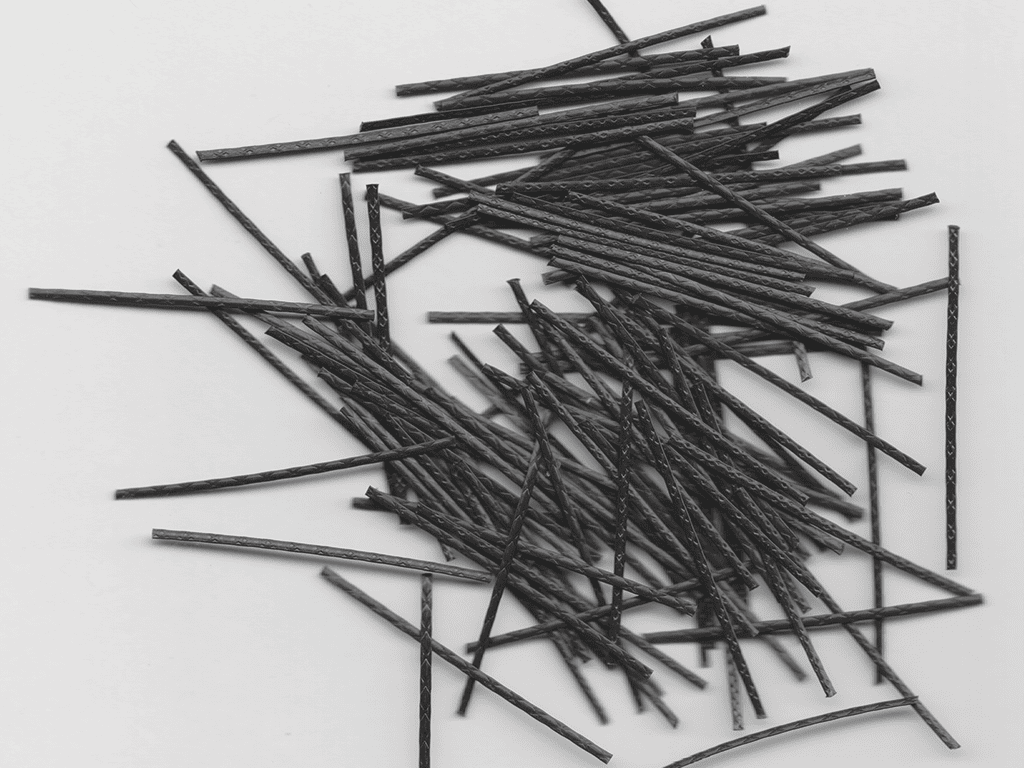

One technology available right now is recycled macro synthetic fibre (MSF) concrete reinforcement, which is used as part of the ground support system in underground excavations.

MSF was introduced to the local mining market by BarChip over 20 years ago. Synthetic fibres eliminated problems with corrosion of steel reinforcement, improved worker safety and reduced maintenance closures. A rapid adoption followed, and MSF is now used in nearly every underground mining operation across the country.

An unknown benefit of MSF at that time is that it’s the lowest carbon footprint reinforcement system on the market, which has only recently been confirmed with the publication of EPD’s.

Although many fibre products exist in the market today, BarChip’s R-Series fibre is the only one made with recycled plastic that can be used in deep mine ground support work.

BarChip Marketing Manager Geoff Sedgman explains the biggest issue with using recycled plastics is maintaining performance. “Every percentage point of impurity in the recycled plastic results in an increasing loss of ductility performance in the final product,” he said. “BarChip has found the right balance of recycled polypropylene (PP), virgin PP, and manufacturing processes, to ensure R-Series maintains-performance at large deflection.”

BarChip Marketing Manager Geoff Sedgman explains the biggest issue with using recycled plastics is maintaining performance. “Every percentage point of impurity in the recycled plastic results in an increasing loss of ductility performance in the final product,” he said. “BarChip has found the right balance of recycled polypropylene (PP), virgin PP, and manufacturing processes, to ensure R-Series maintains-performance at large deflection.”

BarChip R-Series was EPD certified in 2020, which allows its environmental impact in comparison to alternative products to be accurately calculated.

Since the R-Series first hit the market, BarChip has recycled more than 3,700 tonnes of plastic for re-use in ground support works. That’s a saving of over eight million kilograms of carbon compared to non-recycled MSF products, enough to power more than 1,500 homes for a year.

Sedgman added that in Australian mining, the market for fibre is estimated to be around 300 tonnes per month. “With BarChip R-series, this represents an opportunity to recycle over 70 tonnes per month directly into ground support works. That’s a saving of over 1,800 tonnes of carbon each year, enough to power 350 homes, all from one material selection.”

While the benefit is comparatively small compared to larger investments like renewable energy or hydrogen cell batteries, the savings from low emission products like BarChip can be realised right now, with no investment required. The cumulative effect of products like BarChip across the entire supply chain can have a marked impact towards net zero by 2050.

Just like mining companies, BarChip is strongly focused on continuously improving its own supply chain and its subsequent environmental impact. This has flowed into the company’s product packaging, with product bags added directly to the concrete to eliminate waste and pallets made with recycled plastic. Once used, they can be delivered to the nearest recycling centre and given a ‘third life’.

In 2023, the company opened a new factory in Paraguay that is 100 percent powered by renewable energy, providing the lowest carbon footprint fibre reinforcement product on the market. BarChip now has manufacturing operations on three continents, ensuring a strong and stable product supply around the world.

For more information, call 1300 131 158, email [email protected], or visit https://barchip.com/