Revo Group bringing a high-tech approach to NDT solutions

Non-destructive testing (NDT) plays a critical role in the safe and reliable operation of many products, transportation systems and resource industry structures bring used every day around the world.

A range of industries now accept that NDT is a crucial part of quality control and is necessary wherever there is the need to be sure of the safety, reliability, and dependability of daily operations.

A local NDT specialist, Anthony Lima of Revo Group, says it can also save lives.

We caught up with Mr Lima recently and asked him what would be the worst-case scenario if an item failed after not being regularly inspected or tested.

“There are a number of really bad outcomes. And number one, obviously it that someone dies. That is literally what can happen. The second one is that there is a systemic failure in the infrastructure that results in massive environmental damage.

“There is also the cost to the bottom line through lost production and then there is reputational damage.”

Historic service

The history of NDT dates back to the early 1800s when visual inspection was used to detect surface cracks on metal parts. It is believed that the first non-destructive testing method used was magnetic particle inspection (MPI), which was developed in the 1860s.

Since then and now, non-destructive testing is carried out to ascertain that the components or materials being used are not damaged or faulty and are fit to be used by personnel. The results of testing can show whether the components need to be repaired or if they are safe for operation.

The global NDT market was estimated to be valued at around US$6.6 billion in 2022 and it is expected to hit around US$44.31 billion by 2032, registering a CAGR of 10.32% during the forecast period from 2023 to 2032.

The Asia-Pacific is region is predicted to expand at the fastest CAGR during the forecast period.

However, despite its importance, Mr Lima says that quite often companies are not testing as often as they should.

“One of the key problems a lot of businesses have is that they are either replacing assets too soon, or they are not replacing them soon enough, because they’re not being inspected properly.”

Mr Lima says one of the keys to overcoming this is the use of technology and NDT companies have a strong reputation for having been innovators for many years.

Mr Lima says one of the keys to overcoming this is the use of technology and NDT companies have a strong reputation for having been innovators for many years.

“For me it is about the best way of using the right technology that will help identify the areas of risk at the right time,” Mr Lima says.

A wide range of NDT technologies can be utilised for a wide range of industries to test a wide range of equipment.

“NDT is used to test oil and gas pipelines, examine power infrastructure – it can be used on a heap of different assets in a whole lot of different locations and situations.

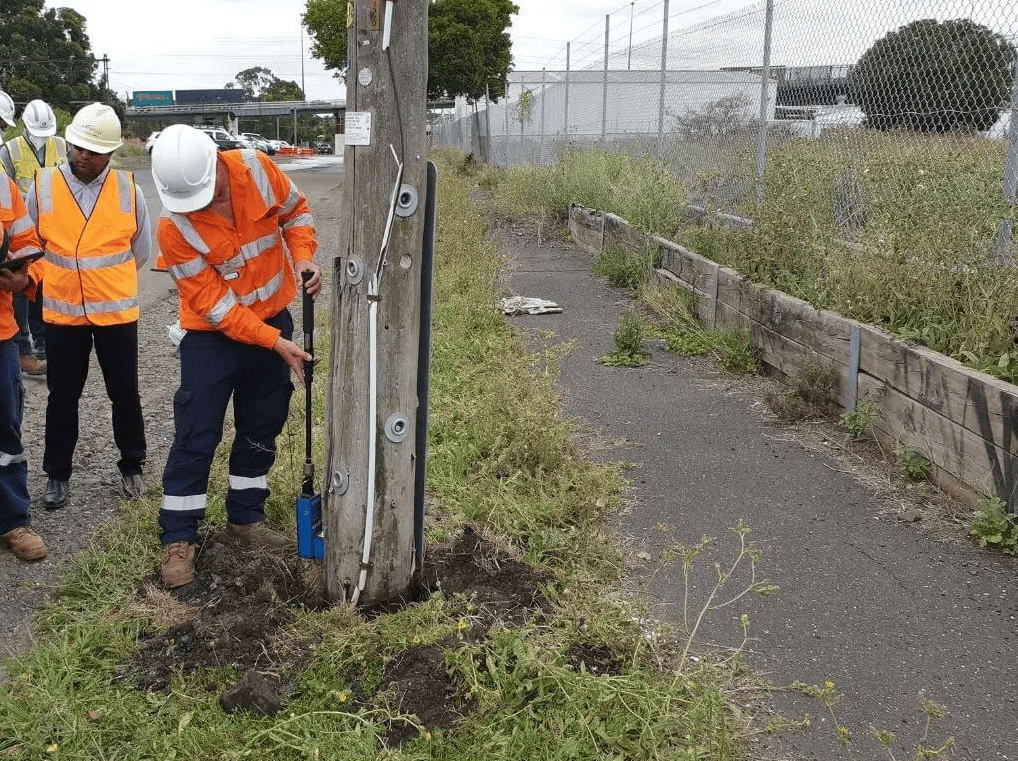

“For example, a mining a company may have timber that is below ground and you might wonder how are we going to assess the reliability of that item.

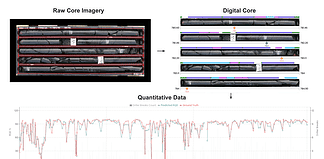

“Revo Group has developed our own PortaSCAN device which can check that timber and make sure that it’s okay before it fails, or in some cases, provide the evidence that it may need replacing.”

One of the real values of modern NDT technology is that it can be utilised when an asset is working, meaning a mine, or factory or oil and gas field ‘s production can still continue while testing is being conduct. And it is all done non-destructively.

“it’s very quick and it’s very thorough and by undertaking it you can get peace of mind that this piece of infrastructure is actually structurally safe, or if it may it need replacing.”

Along with being a leading provider of niche asset inspection equipment and services around the world, Revo Group’s highly experienced team also provide asset management, design, training and inspection services, software, and technology.

The company is also a designer and creator of highly specialised systems such the PortaSCAN and its own cutting-edge software.

“Revo Group has built a strong reputation with customers for safety, quality and dependability in Australia, New Zealand, and Southeast Asia,” Mr Lima says.

“We have built our approach around the idea of delivering customers with a full system review. This involves both modern and traditional inspection techniques, material inspection and assessment, calibration of design and inspection rules, and risk-based rules using engineering principles.

“It is really a pretty fascinating environment from the point of view of there are a number of ways we can prevent companies from having a catastrophic incident such as an oil spill or the release of something like high toxic fluid. Preventing incidents like that is a win-win for everyone.”

It is thanks to the dedication and innovation of companies like Revo Group that miners, oil and gas companies and civil firms can feel a lot more comfortable about the reliability and safety of their operations and that their workers can go home safely every day.

For more information visit www.revogroupau.com