Driving businesses forward with Duons

The mining industry continues to experience a rapid growth in the uptake of monitoring and control technology off the back of a rise in automation, electrification and digital transformation. The need to monitor critical plant equipment, machinery and people in real-time not only serves to improve safety and productivity, but helps drive process efficiencies and reduce costs through preventative maintenance and actionable insights.

This is particularly important for fleet managers and maintenance teams to improve asset utilisation and performance from informed decision making about plant and processes. These can have huge implications on an operation, allowing systems to be monitored remotely, therefore minimising risk to personnel, and enabling a faster response to potential incidents.

Predictive maintenance is one area where the right monitoring and control technology play a key role in an industrial mining environment. This is achieved by integrating specialised monitoring technology within specific plant components that alerts maintenance personnel in real-time when unexpected faults occur. Issues can be identified and rectified immediately, maximising equipment availability and operational continuity.

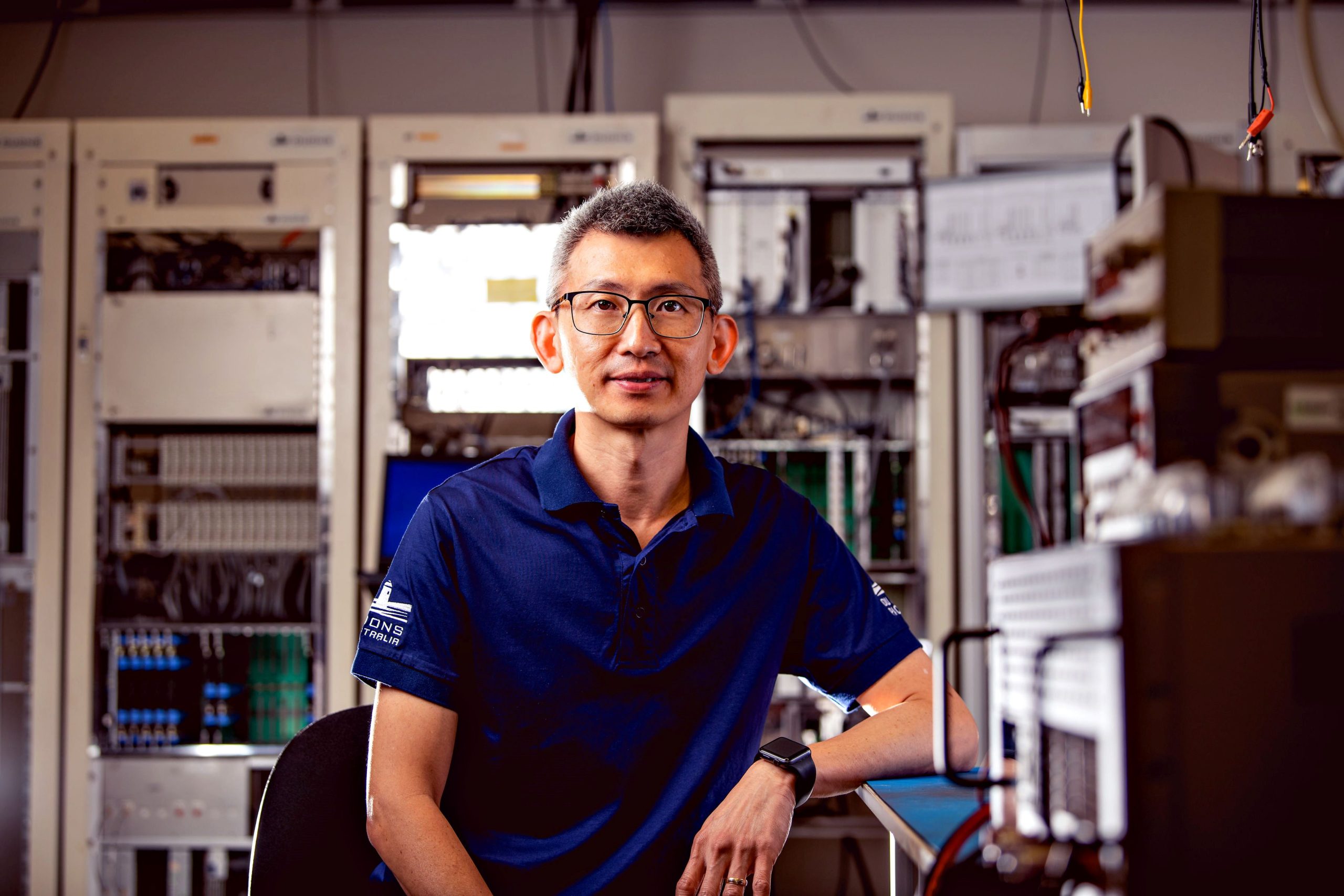

Global French-owned company Duons (part of the Vallee Group) is a telecommunications integrator and technology support partner to some of Australia’s major Government and manufacturing organisations.

In 2006, the company opened a repair and logistics centre in Brisbane to provide support for the maintenance of legacy equipment for the country’s largest telco, Telstra. Duons has since continued to leverage its global network and in-house expertise to expand its value and service offering to clients across Australia and the Asia-Pacific region.

The Australian Mining Review spoke with Duons Business Development Executive Benoit Hanne, to learn more about the company’s suite of monitoring and control technology, and the vital role they play in the maintenance of infrastructure and remote assets.

“At Duons, we’re proud to have represented AKCP in Australia since 2019. They commenced business in the USA in 1981, and have over 40 years’ experience in professional sensor solutions,” Mr Hanne said.

“AKCP essentially created the market for networked temperature, environmental and power monitoring in the IT sector. With over 150 employees and 250,000 installations, they are the world’s oldest and largest manufacturer of networked wired and wireless sensor solutions. This gives our customers the confidence they are receiving trusted technology that’s been tried and tested over decades.

“Their R&D centres specialise in SNMP-based networking and embedded device technology, employing the best and brightest from top universities to develop new products, whilst improving existing ones.”

AKCP created and still define the market for network-based environmental and security monitoring solutions. By setting the standards for technical achievement and innovation, the company remains at the front of the pack when it comes to industry standards in the field of SNMP-based monitoring.

As mining companies rely heavily on equipment reliability and worker safety, AKCP intelligent sensors, combined with a SP+ base unit, will monitor temperature, humidity, vibration or air velocity to help identify potential equipment failures before they occur, thus preventing potential hazards and safety incidents.

The impact on the environment is also an important consideration within the mining industry. In order to limit environmental factors such as air pollution or water damage, AKCP smoke detectors and water spot sensors offer a reliable solution to control and monitor these areas.

Mr Hanne says their monitoring solutions can help mining companies improve their operational and cost efficiencies.

“Implementing sensors such as an inline power meter, an AC voltage sensor, or an isolated DC voltage sensor, contributes to improved equipment performance, energy consumption, and other key metrics. Companies can identify areas where efficiencies can be improved, as well as opportunities to reduce waste.

“It’s not just the about the cost of your equipment, but the cost of not being able to supply products and services your company relies upon,” he said.

Aside from AKCP monitoring solutions, Duons also provide high-level complex electronic repairs to their clients.

As industrial electronics can breakdown at any given time, and the fact that equipment may be superseded, newly purchased replacements from a manufacturer may likely require modification in the machinery and infrastructure. This can prove very costly if production delays occur. Instead of replacing with new components, Duons can assess, repair, or refurbish any electronic process control or test equipment irrespective of function, age, manufacturer, or model.

The company aims to find the fault, then repair and replace the components that from experience are likely to fail in the future. Duons also offer a no obligation repair assessment as part of its component level electronics servicing, which can save customers in part replacement costs.

This consists of repairs to industrial electronic, process control and mining equipment, either onsite repair or unit despatch to its Geebung facility, and a quick turnaround to get machinery back into production.

“We offer a wide range of tailored options for our clients, from board swap to complex re-engineering including, but not limited to, PCBs, power supply boards, processor boards, PLCs, RF boards, serial communication boards, rectifier boards, and transformer boards,” Mr Hanne added.

“By delivering an extra edge in technical services and repair solutions, we are an integral part of Telstra’s continued success and responsible for key equipment critical to

Telstra’s Universal Service Obligation (USO)

– a legislated requirement to provide all people in Australia with access to Standard Telephone Services (STS).

“We’re proud to be the major repair centre for Telstra’s IRT & SWING for Australia and excited about expansion into other industries.” AMR

Duons Australia

P 1300 487 255

W https://www.duons.com.au/