Making an Impact with SIMEX Twin Header Rock Grinders

Miners are regularly faced with undertaking earthmoving works in and around challenging structures and surfaces, both above and below ground. That’s why operators are increasingly turning to high performance earthmoving attachments like rock grinders that help cut through the toughest surfaces with little fuss. When conventional excavation systems are too weak and percussion tools have little impact, Simex twin header rock grinders (also known as rotary cutters) are the ideal solution for the most complex applications. Ideal for trenching in hard and compact ground, rock wall and concrete profiling, tunnelling, dredging, demolition, and quarrying, the Simex range is renowned for its work in finishing operations where high precision, minimum disturbance and aesthetic results are required. Simex twin header rotary cutters are available in a range of models to suit 2.5 to 75 tonne excavators, designed to meet the performance demands of mines, quarries and tunnels. The twin headers can be used to cut through varied degrees of rock hardness of up to 85 mPa. The rotary cutters showcase their full versatility in mining and quarry works, not only ensuring selective breaking of the rock mass for wall stability open pit extraction, but increasing profitability, producing a crushed material that often doesn’t require further crushing by additional equipment. In comparison to traditional rock grinding methods such as explosives or hydraulic rockbreakers, the Simex twin header range offers a number of unique advantages which make them the attachment of choice for hard surfaces – more accurate profiling and precise cuts, versatility in narrow and deep excavations, continuous operate on and greater efficiency, and minimisation of fractures within the rock mass. Their quiet operation and low vibration emission (<87 dB) also make them ideal when working near sensitive areas such as residential zones, hospitals, schools, bridges and other existing infrastructure.

Unrivalled Performance

The new generation Simex attachments are manufactured to the highest quality standards, and are the product of over 30 years of innovation combined with feedback from end users on the ground. The Simex twin header rotary cutters showcase the perfect balance between productivity and precision, making hard jobs easy and allowing operators to cut intocorners more efficiently than ever. Featuring patented technology, the direct drive high displacement hydraulic piston motor, offers high torque and high performance, enabling operators to consistently bore through the toughest materials without losing power. The direct drive motor does not require lubrication or other routine maintenance. A filter on the feed and drainage line are both integrated, protecting the hydraulic system from any external impurities, which can damage or reduce the performance of both the excavator and the equipment. Additional protection from pressure peaks is provided on drainage line by an accumulator and a fuse and on feed line by a flow limiting valve. The latter also allows easy coupling with various excavator models and sizes, facilitating installation and calibration operations. With replaceable anti-wear plates, and mechanical gaskets fitted on the drums, the equipment will also be safeguarded from dust, allowing the rotary cutters to work completely submerged either in the ground, or in water up to a maximum depth of 30 metres. The frame’s unique shape reduces the distance between the drums and improves the total working width. Furthermore, milled material is discharged from the trench without getting stuck in the structure due to the symmetry of the frame, which also allows hoses to be hooked up at sides and front. The rotary cutters can be rotated 90 degrees thanks to square holes in the coupling plate, which makes the equipment even more productive and versatile when it comes to different applications.

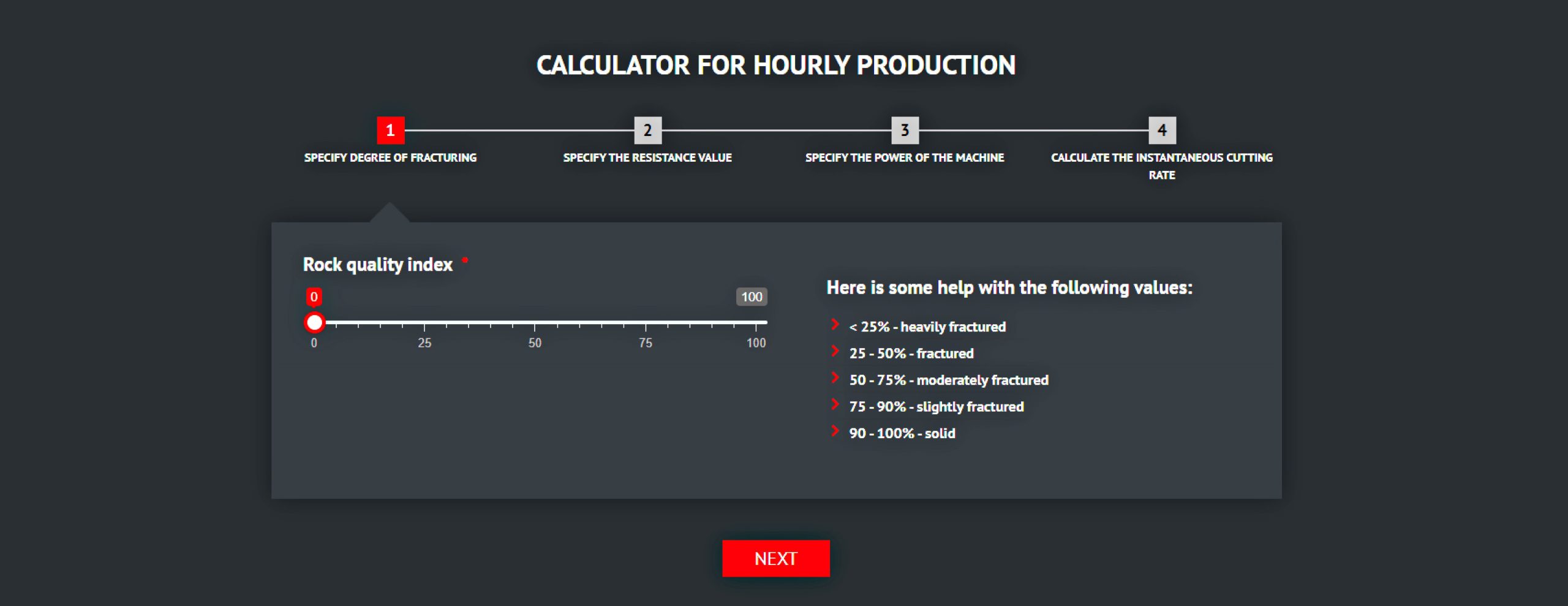

Estimate your hourly production with the new SIMEX calculator

Buying new equipment can be costly, and as with all important business decisions, it’s a good idea to seek the right advice. The team of experts at the Simex factory in Italy have launched a new tool that calculates the theoretical hourly production if using Simex high performance twin header rotary cutters. The calculator will recommend the most suitable model based on the material you need to work with. The versatile Simex twin header rotary cutters are designed to suit a range of applications, from trenching in the road sector, passing through the vertical profiling of concrete or rock walls in construction and infrastructure, up to the toughest quarrying or tunnelling work. The calculator can be accessed via https://simex-drumcutters.com/en-us/tf/

Contact your local SIMEX dealer

QLD/NT/PNG: QLD Rock Breakers

VIC/SA/TAS: Walkers Hammers

NSW: Groundtec

WA: Total Rockbreaking Solutions

For more information, visit: www.attachmentspecialists.com.au/simex