Water is Life | Aussie Pumps

It’s not an original concept but it was widely promulgated by Ion Idriess, who although is mainly famous as an author, was a prospector, stockman in the Light Horse Brigade in Palestine in the First World War and later became a journalist.

Idriess realised the potential of Australia.

He travelled over a lot of it on horseback or camel.

He understood the need for us to do something about water security for the Inland.

Not much has happened and that is why water is so precious for our industry.

The uses of water in mining are manifold.

Mines don’t want too much of it.

Floods can be extremely inconvenient, and they certainly don’t want too little either.

One thing is for sure, we wouldn’t have an industry without adequate water supply.

Imagine Kalgoorlie without the pipeline!

WHERE AUSSIE PUMPS FITS IN

“Here at Australian Pump Industries (Aussie Pumps) we study applications and try to learn more about those areas of the industry where we know we are proficient.

We never attempt to do everything but what we do, we do extremely well”, said Aussie Pumps Chief Engineer, John Hales.

KEEPING MINES DRY

Some of Aussie’s team had their early years as mine dewatering specialists. They come out of the old Pacific Pumps that introduced deep well submersibles to Australia back in the early 60’s.

What a difference that made to the coal mines in New South Wales.

The Hunter and the southern coal mines in NSW would have been very dangerous places without those pumps.

Today, deep well submersible pumps are common place and Aussie doesn’t get involved in that particular configuration.

What we do is specialise in self priming centrifugal pumps of various types for mine dewatering.

“We also focus on positive displacement piston pumps, mainly used in cleaning applications but can also be used for dust suppresion as well”, said Hales.

FLOOD RESCUE PUMPS

Aussie’s range of self priming centrifugal diesel drive trash pumps can be found on mines all over Australia and the South Pacific.

Aussie’s big 6” pumps saved the town of Juba, capital of South Sudan. A bank of 25 of these pumps shifted the direction of the Nile River when it was in flood in August last year.

“We haven’t done anything quite that dramatic in Australia”, said Hales.

“But certainly Local Government bodies and mines are buying our self priming centrifugal pumps in place of dry prime pumps now, and for very good reasons.”

One reason is they’re lower cost.

Most importantly the operating costs are minimal.

The pump has a big cast body that includes a priming tank.

Those big shoulders on the product enable it to be primed with water, enabling it to draft through a vertical lift of 7.6 metres.

That makes it ideal for moving floodwater from one place to another with 6,000 litres per minute flow rate.

That’s 360,000 litres per hour and almost nine million litres per 24 hour working day.

The big pumps have a huge open impeller that will pass solids in suspension, a heavy duty volute, and an oil lubricated tungsten titanium carbide mechanical seal.

Most importantly, they feature a front clean out port that only takes a matter of seconds to open up and clear any blockage the pump may encounter.

The company builds in a 152 litre fuel tank that will allow the pump to run for eleven hours before refuelling.

There is almost nothing to go wrong in the unit which is why Australian miners love them.

No compressors, no vacuum pumps, no valves to clog up or wear, no springs!

“They’re a masterful piece of simple engineering”, said Hales.

The pumps are driven with an 80 hp four cylinder Deutz air cooled diesel engine.

They do a mighty job.

Aussie chose Deutz’s air cooled drive because of that simple reason.

No radiator, no radiator hoses, but designed for operating in severe environments.

The engine is protected with a LOFA control panel to protect it from low oil pressure, high oil temperature and V-belt failure with the shutdown system.

The machine also has a shock mounted control panel with water resistant housing that includes an hourmeter, ammeter, tachometer and alternator failure light.

These big 6” pumps can be skid mounted or supplied on a heavy duty site trailer, both versions are fitted with an integrated lift bar!

IT’S REALLY IS DESIGNED TO MINE!

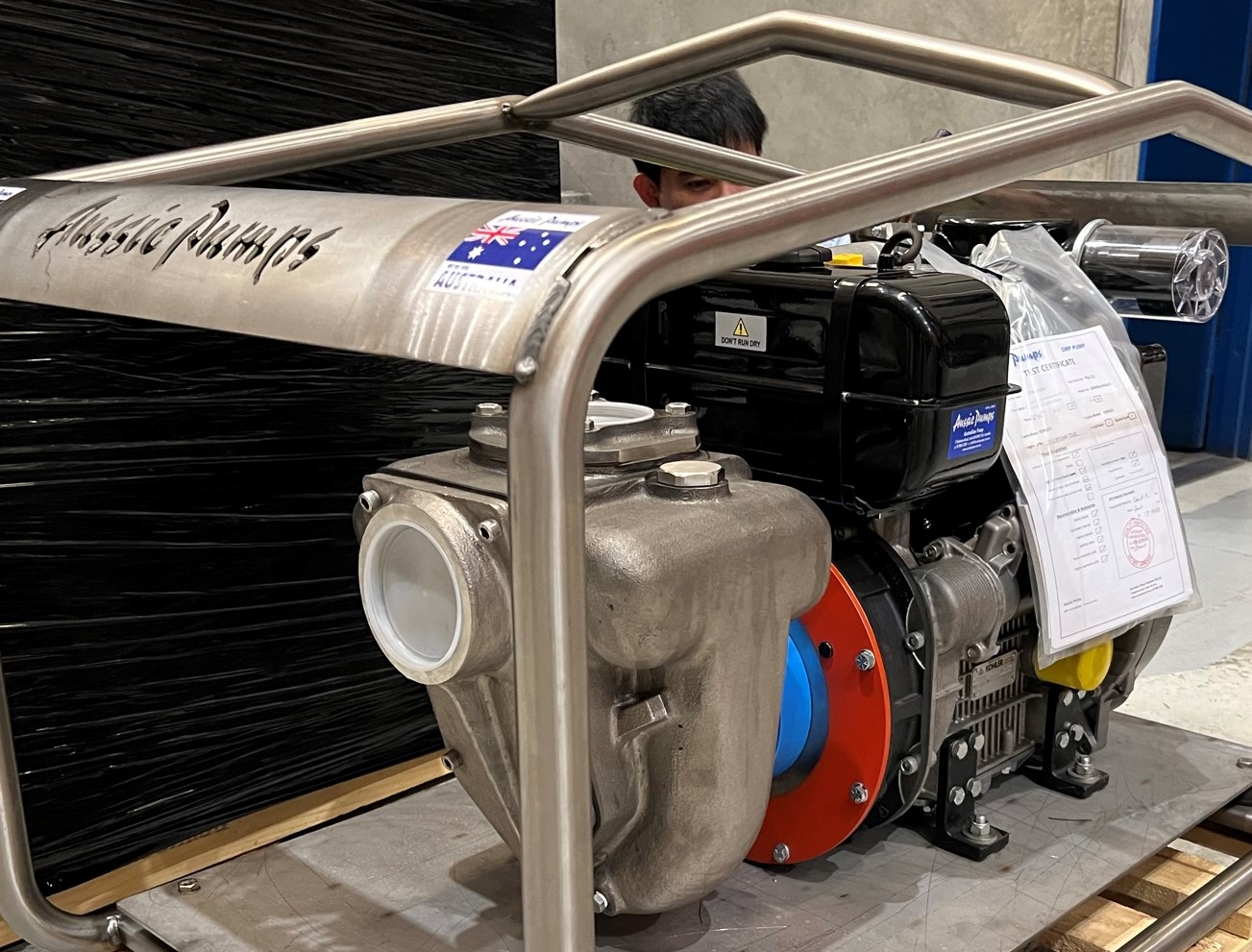

AUSSIE MINE BOSS TRASH PUMPS

Aussie’s Mine Boss range started out with 2”, 3” and 4” pumps, driven by Yanmar L series air cooled diesel engines.

These compact single cylinder diesels do a mighty job, even in the toughest conditions. The company sets them up in super heavy duty stainless steel ‘Mine Boss’ frames, capable of rough site operating conditions.

The machines are all designed with a front clean out port built into the bowl, heavy duty silicon carbide mechanical seals, and big open impellers to pump solids in suspension.

The 3” pump will pump 1” spherical solids, the 4” will do 1 ½”. They come equipped with E-stop, battery isolation, a fire extinguisher and fluro tape to make them very obvious on site, night or day.

The frames offer a stainless steel sub base, anti vibration mounts and a heavy duty integrated lift bar.

MINE BOSS TRANSFER PUMPS

“Again we do these in self priming pumps in either lightweight aluminium, driven by Yanmar diesels, or alternatively, in heavy duty cast iron configuration and sometimes even in 316 stainless steel.

The pumps are capable of pumping significantly higher heads than the trash pump range.

They are fitted with closed impellers, offering extra pressure,” said Hales.

These machines are also built in Aussie’s unique Mine Boss configuration in super heavy duty frames.

They come in 3” and 4” sizes and can offer flows to 1500 lpm.

Cast iron versions have front clean out ports and are regarded by the company as being “semi trash pumps”.

FIRE IN THE HOLE

The company’s engineers realised that one of worst thing that can happen in an operating mine is a fire.

It doesn’t matter whether it’s underground, in which case it’s a massive issue, or in open cut applications, or even in processing plants.

Aussie’s fire pump range of pumps is designed to be lightweight and now come in Mine Boss configuration as well.

The Aussie Fire Chief, powered by L48 4.8HP Yanmar diesel engine weighs only 45 kilos and can

be deployed fast.

It’s often mounted on a ute with a tank.

“We call them Fast Attack vehicles.

We supply the pump and the specialists that build those rigs set them up with high pressure hose reels with sufficient hose and firefighting nozzles to be able to get the job done fast in the event of a fire”, said Hales.

They all come with battery isolation, E-stop, super heavy duty stainless steel frames and fire extinguisher.

They are a great extension to the Mine Boss range.

316 STAINLESS STEEL

These diesel drive machines are new to the company and provide real capability for pumping highly corrosive liquids.

The big 4” pump shown handles 2,200 lpm and is fitted up with Buna or Viton seals and elastomers.

The pump range is available in diesel drive, close coupled electric motor, even hydraulic drive.

You can see them being employed for pumping Ad Blue!

PUMPING FUEL

A lot of this company’s pumps are set up with Viton seals with diesel drive engines for handling fuel for various refuelling jobs.

Those diesel pumps are augmented by a unique range of fuel transfer pumps driven with electric motor.

They are fitted with Atex motors that are flame proof and designed operate in hazardous environments.

They are available in a range of 1 ½” port sizes through to 4”.

The pumps will handle fuel at the rate of up to 2,300 lpm with some Aussie models capable of handling long distance fuel transfer over hundreds of metres of line.

The pumps are heavy duty cast iron construction and all comply with EU directive 2014/34/UE.

CARVER FILTRATE PUMPS

The company has been duly appointed as a distributor for Carver pumps in Australia for a number of years.

Originally starting out in Defence applications for specialty pumps for warships, Australian Pumps now supply the complete range of filtrate pumps as part of the Carver Krogh line.

“It’s great to see these specialty filtrate pumps doing such a magnificent job in what can only be described as extremely abrasive applications”, said Hales.

KEEP IT CLEAN

Along with the Mine Boss range, Aussie developed a great range of top quality diesel drive high pressure cleaners, up to 500 bar (7,300 psi).

Those machines are built in the Mine Boss configuration, super heavy duty stainless steel frame.

That’s E-stop, battery isolation, lifting bar, and more recently heavy duty stainless steel hose reels with long length hoses, up to 50 metres long.

“Big reels on these units are a great advantage for the operator! It makes them safer, more efficient, with the ability to operate within a range of 30 m on the basic reel or 100 metres in total using the 50 m reel system.

“Miners love them, operators love them and we’re proud of the design work our engineers did”, said Hales.

THE PRIVILEGE OF WORKING IN MINING

“Knowing how vital the Australian Mining Industry is to the economy, it’s a great privilege for us to be involved in coal, bauxite, iron ore, copper and gold!

We’re even developing specialty pumps now for drillers to facilitate mud pump mixing.

We’re working with some of the best in the business to help develop that and the drilling industry is sitting up and taking notice.

“Imagine that, there wouldn’t be a mining industry without the prospectors and the drillers to find the material in the first place!”, said Hales.

For further information on Aussie’s great range of pumps, call 02 8865 3500 or visit aussiepumps.com.au.

Training courses are also available ABSOLUTELY FREE, on Safety, Pumpology and Drain Cleaning Jetter operation.