Celebrating 20 years since the installation of Gekko’s innovative processing plant at the Ballarat Gold Mine

Gekko Systems, an award-winning global leader in the design, development, manufacturing, and commercialisation of mineral processing technology and services, is celebrating two decades since the installation of its innovative mineral processing plant at the Ballarat Gold Mine, which is now owned by Victory Minerals.

Gekko Systems is known for its strong technical and client support capabilities, and has maintained significant collaboration with the Ballarat Gold Mine. Gekko’s success in delivering cutting-edge solutions has made it a trusted partner for the Ballarat Gold Mine and other mining companies around the world.

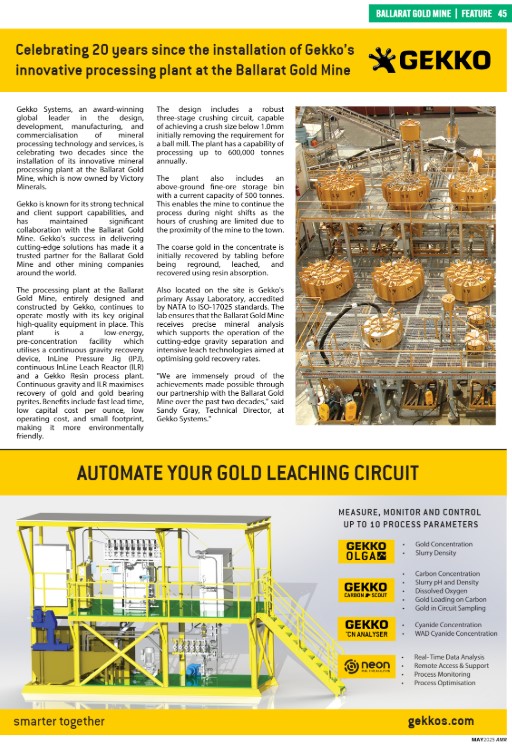

The processing plant at the Ballarat Gold Mine, entirely designed and constructed by Gekko, continues to operate mostly with its key original high-quality equipment in place. This plant is a low-energy, pre-concentration facility which utilises a continuous gravity recovery device, InLine Pressure Jig (IPJ), continuous InLine Leach Reactor (ILR) and a Gekko Resin process plant. Continuous gravity and ILR maximises recovery of gold and gold bearing pyrites. Benefits include fast lead time, low capital cost per ounce, low operating cost, and small footprint, making it more environmentally friendly.

The design includes a robust three-stage crushing circuit, capable of achieving a crush size below 1.0mm initially removing the requirement for a ball mill. The plant has a capability of processing up to 600,000 tonnes annually.

The plant at the Ballarat Gold Mine also includes an above-ground fine-ore storage bin with a current capacity of 500 tonnes. This enables the mine to continue the process during night shifts as the hours of crushing are limited due to the proximity of the mine to the town.

The coarse gold in the concentrate is initially recovered by tabling before being reground, leached, and recovered using resin absorption.

Also located on the site is Gekko’s primary Assay Laboratory, accredited by NATA to ISO-17025 standards. The lab ensures that the Ballarat Gold Mine receives precise mineral analysis which supports the operation of the cutting-edge gravity separation and intensive leach technologies aimed at optimising gold recovery rates.

“We are immensely proud of the achievements made possible through our partnership with the Ballarat Gold Mine over the past two decades,” said Sandy Gray, Technical Director, at Gekko Systems.”