Coronado takes Mammoth steps at Curragh

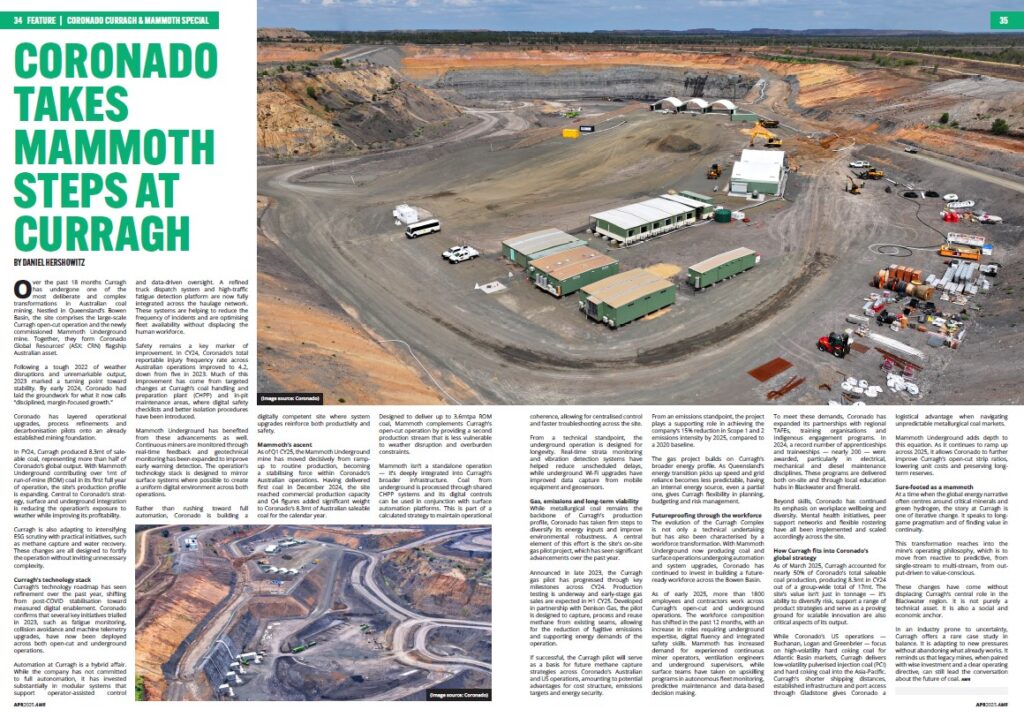

Over the past 18 months Curragh has undergone one of the most deliberate and complex transformations in Australian coal mining. Nestled in Queensland’s Bowen Basin, the site comprises the large-scale Curragh open-cut operation and the newly commissioned Mammoth Underground mine. Together, they form Coronado Global Resources’ (ASX: CRN) flagship Australian asset.

Following a tough 2022 of weather disruptions and unremarkable output, 2023 marked a turning point toward stability. By early 2024, Coronado had laid the groundwork for what it now calls “disciplined, margin-focused growth.”

Coronado has layered operational upgrades, process refinements and decarbonisation pilots onto an already established mining foundation.

In FY24, Curragh produced 8.3mt of saleable coal, representing more than half of Coronado’s global output. With Mammoth Underground contributing over 1mt of run-of-mine (ROM) coal in its first full year of operation, the site’s production profile is expanding. Central to Coronado’s strategy, surface and underground integration is reducing the operation’s exposure to weather while improving its profitability.

Curragh is also adapting to intensifying ESG scrutiny with practical initiatives, such as methane capture and water recovery. These changes are all designed to fortify the operation without inviting unnecessary complexity.

Curragh’s technology stack

Curragh’s technology roadmap has seen refinement over the past year, shifting from post-COVID stabilisation toward measured digital enablement. Coronado confirms that several key initiatives trialled in 2023, such as fatigue monitoring, collision avoidance and machine telemetry upgrades, have now been deployed across both open-cut and underground operations.

Automation at Curragh is a hybrid affair. While the company has not committed to full autonomation, it has invested substantially in modular systems that support operator-assisted control and data-driven oversight. A refined truck dispatch system and high-traffic fatigue detection platform are now fully integrated across the haulage network. These systems are helping to reduce the frequency of incidents and are optimising fleet availability without displacing the human workforce.

Safety remains a key marker of improvement. In CY24, Coronado’s total reportable injury frequency rate across Australian operations improved to 4.2, down from five in 2023. Much of this improvement has come from targeted changes at Curragh’s coal handling and preparation plant (CHPP) and in-pit maintenance areas, where digital safety checklists and better isolation procedures have been introduced.

Mammoth Underground has benefited from these advancements as well. Continuous miners are monitored through real-time feedback and geotechnical monitoring has been expanded to improve early warning detection. The operation’s technology stack is designed to mirror surface systems where possible to create a uniform digital environment across both operations.

Rather than rushing toward full automation, Coronado is building a digitally competent site where system upgrades reinforce both productivity and safety.

Mammoth’s ascent

As of Q1 CY25, the Mammoth Underground mine has moved decisively from ramp-up to routine production, becoming a stabilising force within Coronado’s Australian operations. Having delivered first coal in December 2024, the site reached commercial production capacity and Q4 figures added significant weight to Coronado’s 8.3mt of Australian saleable coal for the calendar year.

Designed to deliver up to 3.6mtpa ROM coal, Mammoth complements Curragh’s open-cut operation by providing a second production stream that is less vulnerable to weather disruption and overburden constraints.

Mammoth isn’t a standalone operation — it’s deeply integrated into Curragh’s broader infrastructure. Coal from underground is processed through shared CHPP systems and its digital controls can be used in conjunction with surface automation platforms. This is part of a calculated strategy to maintain operational coherence, allowing for centralised control and faster troubleshooting across the site.

From a technical standpoint, the underground operation is designed for longevity. Real-time strata monitoring and vibration detection systems have helped reduce unscheduled delays, while underground Wi-Fi upgrades have improved data capture from mobile equipment and geosensors.

Gas, emissions and long-term viability

While metallurgical coal remains the backbone of Curragh’s production profile, Coronado has taken firm steps to diversify its energy inputs and improve environmental robustness. A central element of this effort is the site’s on-site gas pilot project, which has seen significant advancements over the past year.

Announced in late 2023, the Curragh gas pilot has progressed through key milestones across CY24. Production testing is underway and early-stage gas sales are expected in H1 CY25. Developed in partnership with Denison Gas, the pilot is designed to capture, process and reuse methane from existing seams, allowing for the reduction of fugitive emissions and supporting energy demands of the operation.

If successful, the Curragh pilot will serve as a basis for future methane capture strategies across Coronado’s Australian and US operations, amounting to potential advantages for cost structure, emissions targets and energy security.

From an emissions standpoint, the project plays a supporting role in achieving the company’s 15% reduction in Scope 1 and 2 emissions intensity by 2025, compared to a 2020 baseline.

The gas project builds on Curragh’s broader energy profile. As Queensland’s energy transition picks up speed and grid reliance becomes less predictable, having an internal energy source, even a partial one, gives Curragh flexibility in planning, budgeting and risk management.

Futureproofing through the workforce

The evolution of the Curragh Complex is not only a technical undertaking but has also been characterised by a workforce transformation. With Mammoth Underground now producing coal and surface operations undergoing automation and system upgrades, Coronado has continued to invest in building a future-ready workforce across the Bowen Basin.

As of early 2025, more than 1800 employees and contractors work across Curragh’s open-cut and underground operations. The workforce composition has shifted in the past 12 months, with an increase in roles requiring underground expertise, digital fluency and integrated safety skills. Mammoth has increased demand for experienced continuous miner operators, ventilation engineers and underground supervisors, while surface teams have taken on upskilling programs in autonomous fleet monitoring, predictive maintenance and data-based decision making.

To meet these demands, Coronado has expanded its partnerships with regional TAFEs, training organisations and Indigenous engagement programs. In 2024, a record number of apprenticeships and traineeships — nearly 200 — were awarded, particularly in electrical, mechanical and diesel maintenance disciplines. These programs are delivered both on-site and through local education hubs in Blackwater and Emerald.

Beyond skills, Coronado has continued its emphasis on workplace wellbeing and diversity. Mental health initiatives, peer support networks and flexible rostering have all been implemented and scaled accordingly across the site.

How Curragh fits into Coronado’s global strategy

As of March 2025, Curragh accounted for nearly 50% of Coronado’s total saleable coal production, producing 8.3mt in CY24 out of a group-wide total of 17mt. The site’s value isn’t just in tonnage — it’s ability to diversify risk, support a range of product strategies and serve as a proving ground for scalable innovation are also critical aspects of its output.

While Coronado’s US operations — Buchanan, Logan and Greenbrier — focus on high-volatility hard coking coal for Atlantic Basin markets, Curragh delivers low-volatility pulverised injection coal (PCI) and hard coking coal into the Asia-Pacific. Curragh’s shorter shipping distances, established infrastructure and port access through Gladstone gives Coronado a logistical advantage when navigating unpredictable metallurgical coal markets.

Mammoth Underground adds depth to this equation. As it continues to ramp up across 2025, it allows Coronado to further improve Curragh’s open-cut strip ratios, lowering unit costs and preserving long-term reserves.

Sure-footed as a mammoth

At a time when the global energy narrative often centres around critical minerals and green hydrogen, the story at Curragh is one of iterative change. It speaks to long-game pragmatism and of finding value in continuity.

This transformation reaches into the mine’s operating philosophy, which is to move from reactive to predictive, from single-stream to multi-stream, from output-driven to value-conscious.

These changes have come without displacing Curragh’s central role in the Blackwater region. It is not purely a technical asset. It is also a social and economic anchor.

In an industry prone to uncertainty, Curragh offers a rare case study in balance. It is adapting to new pressures without abandoning what already works. It reminds us that legacy mines, when paired with wise investment and a clear operating directive, can still lead the conversation about the future of coal.