Engineering Buoyancy – How Coerco redefines liquid control for mining success

In mining and civil infrastructure projects, liquid control is more than just a necessity, it’s a fundamental component of operational success. From the containment and transport of water to the stability of pipelines and pumps in volatile environments, the challenges are as complex as they are varied.

Enter Coerco, Australia’s leading specialist in liquid containment, flotation, and movement. From pipeline flotation in remote mines, slurry pipelines and dewatering systems to major hydro projects, Coerco’s engineered solutions are helping global industries master the challenge of liquid containment, movement, and treatment.

Coerco’s reputation spans the globe, built on quality engineering, advanced manufacturing, and an unrelenting commitment to problem-solving. Whether you’re designing an intricate dewatering system, managing tailings, or stabilising a floating pipeline in remote terrain, Coerco provides fit-for-purpose, modular, and scalable systems that redefine what liquid control can achieve.

Innovation that floats above the rest

In high-risk, liquid-intensive industries such as mining, civil construction, and water treatment, the need for reliable, durable, and adaptable liquid management solutions is critical. For more than 30 years, Coerco has provided engineered systems that help keep critical infrastructure stable, safe, and efficient — above and below the surface.

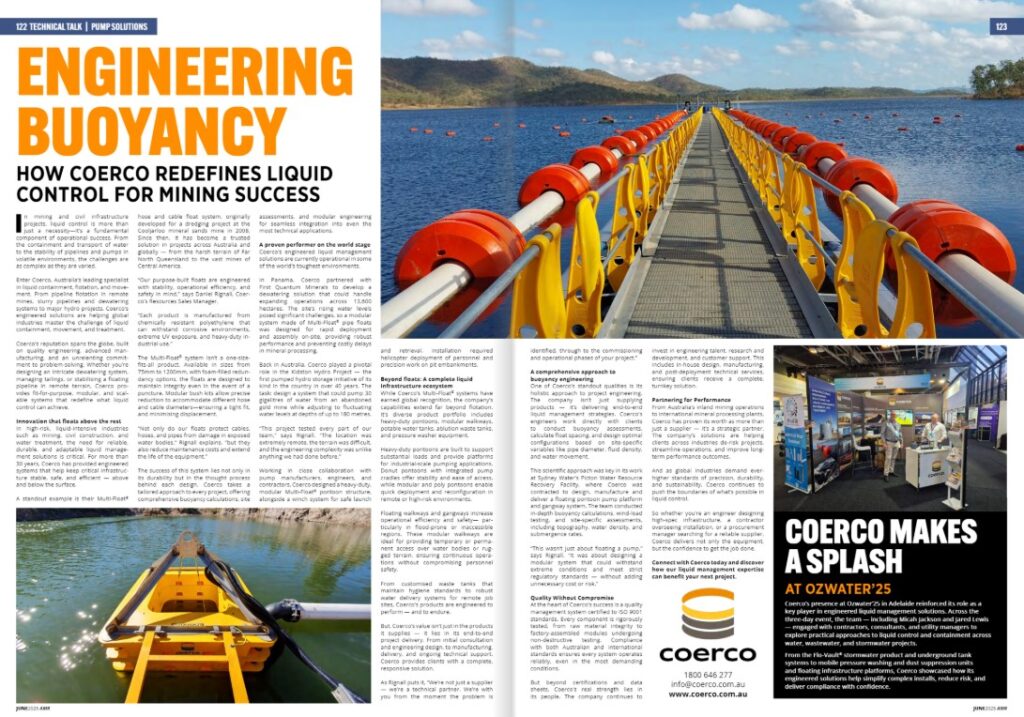

A standout example is their Multi-Float® hose and cable float system, originally developed for a dredging project at the Cooljarloo mineral sands mine in 2008. Since then, it has become a trusted solution in projects across Australia and globally — from the harsh terrain of Far North Queensland to the vast mines of Central America.

“Our purpose-built floats are engineered with stability, operational efficiency, and safety in mind,” says Daniel Rignall, Coerco’s Resources Sales Manager.

“Each product is manufactured from chemically resistant polyethylene that can withstand corrosive environments, extreme UV exposure, and heavy-duty industrial use.”

The Multi-Float® system isn’t a one-size-fits-all product. Available in sizes from 75mm to 1200mm, with foam-filled redundancy options, the floats are designed to maintain integrity even in the event of a puncture. Modular bush kits allow precise reduction to accommodate different hose and cable diameters—ensuring a tight fit, and minimising displacement.

“Not only do our floats protect cables, hoses, and pipes from damage in exposed water bodies,” Rignall explains, “but they also reduce maintenance costs and extend the life of the equipment.”

The success of this system lies not only in its durability but in the thought process behind each design. Coerco takes a tailored approach to every project, offering comprehensive buoyancy calculations, site assessments, and modular engineering for seamless integration into even the most technical applications.

A proven performer on the world stage

Coerco’s engineered liquid management solutions are currently operational in some of the world’s toughest environments.

In Panama, Coerco partnered with First Quantum Minerals to develop a dewatering solution that could handle expanding operations across 13,600 hectares. The site’s rising water levels posed significant challenges, so a modular system made of Multi-Float® pipe floats was designed for rapid deployment and assembly on-site, providing robust performance and preventing costly delays in mineral processing.

Back in Australia, Coerco played a pivotal role in the Kidston Hydro Project — the first pumped hydro storage initiative of its kind in the country in over 40 years. The task: design a system that could pump 30 gigalitres of water from an abandoned gold mine while adjusting to fluctuating water levels at depths of up to 180 metres.

“This project tested every part of our team,” says Rignall. “The location was extremely remote, the terrain was difficult, and the engineering complexity was unlike anything we had done before.”

Working in close collaboration with pump manufacturers, engineers, and contractors, Coerco designed a heavy-duty, modular Multi-Float® pontoon structure, alongside a winch system for safe launch and retrieval. Installation required helicopter deployment of personnel and precision work on pit embankments.

Beyond floats: A complete liquid infrastructure ecosystem

While Coerco’s Multi-Float® systems have earned global recognition, the company’s capabilities extend far beyond flotation. It’s diverse product portfolio includes heavy-duty pontoons, modular walkways, potable water tanks, ablution waste tanks, and pressure washer equipment.

Heavy-duty pontoons are built to support substantial loads and provide platforms for industrial-scale pumping applications. Donut pontoons with integrated pump cradles offer stability and ease of access, while modular and poly pontoons enable quick deployment and reconfiguration in remote or high-risk environments.

Floating walkways and gangways increase operational efficiency and safety—particularly in flood-prone or inaccessible regions. These modular walkways are ideal for providing temporary or permanent access over water bodies or rugged terrain, ensuring continuous operations without compromising personnel safety.

From customised waste tanks that maintain hygiene standards to robust water delivery systems for remote job sites, Coerco’s products are engineered to perform — and to endure.

But, Coerco’s value isn’t just in the products it supplies — it lies in its end-to-end project delivery. From initial consultation and engineering design, to manufacturing, delivery, and ongoing technical support, Coerco provides clients with a complete, responsive solution.

As Rignall puts it, “We’re not just a supplier — we’re a technical partner. We’re with you from the moment the problem is identified, through to the commissioning and operational phases of your project.”

A comprehensive approach to buoyancy engineering

One of Coerco’s standout qualities is its holistic approach to project engineering. The company isn’t just supplying products — it’s delivering end-to-end liquid management strategies. Coerco’s engineers work directly with clients to conduct buoyancy assessments, calculate float spacing, and design optimal configurations based on site-specific variables like pipe diameter, fluid density, and water movement.

This scientific approach was key in its work at Sydney Water’s Picton Water Resource Recovery Facility, where Coerco was contracted to design, manufacture and deliver a floating pontoon pump platform and gangway system. The team conducted in-depth buoyancy calculations, wind-load testing, and site-specific assessments, including topography, water density, and submergence rates.

“This wasn’t just about floating a pump,” says Rignall. “It was about designing a modular system that could withstand extreme conditions and meet strict regulatory standards — without adding unnecessary cost or risk.”

Quality Without Compromise

At the heart of Coerco’s success is a quality management system certified to ISO 9001 standards. Every component is rigorously tested, from raw material integrity to factory-assembled modules undergoing non-destructive testing. Compliance with both Australian and international standards ensures every system operates reliably, even in the most demanding conditions.

But beyond certifications and data sheets, Coerco’s real strength lies in its people. The company continues to invest in engineering talent, research and development, and customer support. This includes in-house design, manufacturing, and post-deployment technical services, ensuring clients receive a complete, turnkey solution.

Partnering for Performance

From Australia’s inland mining operations to international mineral processing plants, Coerco has proven its worth as more than just a supplier — it’s a strategic partner. The company’s solutions are helping clients across industries de-risk projects, streamline operations, and improve long-term performance outcomes.

And as global industries demand ever-higher standards of precision, durability, and sustainability, Coerco continues to push the boundaries of what’s possible in liquid control.

So whether you’re an engineer designing high-spec infrastructure, a contractor overseeing installation, or a procurement manager searching for a reliable supplier, Coerco delivers not only the equipment, but the confidence to get the job done.

Coerco makes a splash at Ozwater’25

Coerco’s presence at Ozwater’25 in Adelaide reinforced its role as a key player in engineered liquid management solutions. Across the three-day event, the team — including Micah Jackson and Jared Lewis — engaged with contractors, consultants, and utility managers to explore practical approaches to liquid control and containment across water, wastewater, and stormwater projects.

From the Flo-Vault® stormwater product and underground tank systems to mobile pressure washing and dust suppression units and floating infrastructure platforms, Coerco showcased how its engineered solutions help simplify complex installs, reduce risk, and deliver compliance with confidence.

Connect with Coerco today and discover how our liquid management expertise can benefit your next project.

Tel: +61 1800 646 277

Email: info@coerco.com.au

Wed: www.coerco.com.au